American Style Heavy Duty Pipe Wrench Plastic Powder Spray-painted

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

American style heavy duty pipe wrench,plastic powder spray-painted

1. Model No:236108

2. Color:green handle

3. Size:8",10"12",14",18",24",36",48"

Samples:

1. Customer have to bear samples charge and courier cost.

2. Samples time: please check with service person if you need samples.

Advantage and Innovation:

1.American style

2. Heavy duty

3.Plastic powder spray-painted

Package and size:

| Model.No. | Spec. | Pcs/ctn. | G.W.(kg) | Mesa.(mm) |

| 236108 | 8"(200mm) | 24 | 12.7 | 250*225*150 |

| 236110 | 10"(250mm) | 24 | 17.4 | 275*255*150 |

| 236112 | 12"(300mm) | 18 | 17.7 | 295*135*210 |

| 236114 | 14"(350mm) | 12 | 15.2 | 330*145*165 |

| 236118 | 18"(450mm) | 12 | 23.6 | 415*305*165 |

| 236124 | 24"(600mm) | 6 | 18 | 525*245*140 |

| 236136 | 36"(900mm) | 5 | 30 | 785*132*250 |

| 236148 | 48"(1200mm) | 3 | 29 | 1090*165*150 |

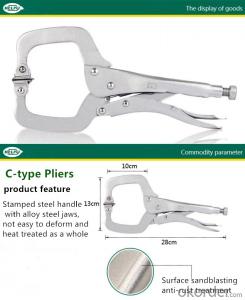

Pictures of pictures:

Order guide:

General Order Information

We take great pride in our work and in the wide variety of products that we offer.

We are experienced in servicing the US market, European market and Asia market .Please be aware that our production lead times depend on specific items and item quantities.

Our success has been based on our professinal for hand tools market.

Check below for more information on placing an order

- Q: How to select the type of pneumatic wrench?

- Compressed air is the most common source of power, but there are also electric or hydraulic applications. In recent years, the use of batteries is also very popular.

- Q: How can the heat treatment process be formulated?

- Because the hardenability of 45 steel is low, the 10% brine solution should be used at a high cooling rate. The workpiece into the water, should be hardened, but not cold, if the workpiece in the brine cold, it is possible to make the workpiece cracking, this is because when the workpiece is cooled to about 180 DEG C when austenite transforms into martensite rapidly caused by excessive stress caused by. Therefore, when the quenched workpiece is cold to the temperature zone, a slow cooling method should be adopted. As the water temperature is difficult to grasp, we must rely on experience to operate, when the workpiece shaking in the water stopped, you can water out of air cold (such as oil, cold better). In addition, the workpiece into the water should be moving, not static, should be in accordance with the geometry of the workpiece, regular movement. The stationary cooling medium plus the stationary workpiece causes uneven hardness and uneven stress, causing the workpiece to become deformed and even crack.45 pieces of quenched and tempered steel after quenching hardness should reach HRC56~59, the possibility of large section low, but not less than HRC48, otherwise, the work has not been fully quenched sorbite, appear even ferrite may in the organization, the organization through tempering, is still retained in the base body, not up to quality objective.

- Q: How to choose torque wrench precision?

- If you learned the quality management and statistics, should know that the accuracy is very simple: take bolt wrench requirement of tolerance of 50%, 5% with a wrench to guarantee the precision of the torque wrench with 10% accuracy, 10% accuracy 20% accuracy of torque, no problem.

- Q: What brand of torque wrenches is best?

- What is the best, this depends on their own needs, the fit is the best. But I personally recommend strong SVETRUCK torque wrench, is a Canadian import brand, cost-effective, comprehensive consideration of the selection of strong SVETRUCK or very suitable.

- Q: Manufacturing process of inner six angle wrench

- Say so complicated, don't die ah, very simple selection of high manganese steel forged six edges, the corresponding length of heating, bending, pickling rinse, dark red (500--700) oil quenching, nonscale is natural black, here is the finished product, the high cost of plating is not good to sell, because people are feeling good is black, here we have a factory is doing business good, very cheap to sell a few dollars a kilogram

- Q: 24, six angle screw with a big wrench?

- M24 inner six corner screw, usually use 12 or 14 wrench, specific needs according to the type of screw to determine.

- Q: Is the inner six angle spanner bent with six angles carbon steel?

- The inner six angle spanner is made of six edges of steel bending, and can also be made of round bar material and six ends milling;Good, six angle wrench, hardness of 45-50, with 45 steel bending and then quenching, attention should be paid to the hardness of quenching.

- Q: Inside the six angle wrench, if required to black appearance, generally do what processing, wear and rust prevention effect will be better? How about the cost?

- In addition, the plating black nickel or black chromium can also achieve your appearance and wear-resistant effect, but the cost is very high, I have not seen such products.

- Q: What problems do sleeve wrenches use?

- Caution with torque wrench:1., pay attention to waterproof, mud, sand and other debris into the wrench handle, torque wrench is strictly prohibited when the use of hammer.2. when using the wrench head to be leveled, force should be uniform, not too hard or exert impact force.3. when the torque wrench issued a "click" sound, to immediately stop the wrench, wrench force to prevent damage to the part of the 4 set to zero in the wrench is strictly prohibited to use, because in this state after no sound signal, easy to overload damage wrenchWhen the 5. wrench is not suitable for a long time, the wrench scale shall be set on the zero position so as to avoid the fatigue failure of the force measuring element.6. during the process of use, if the wrench does not sound, the signal should be stopped immediately for maintenance. After maintenance, the wrench needs to be calibrated and can be used before calibration.

- Q: How can you adjust the guitar chord distance with six angle spanner?

- debuggingThe strings all loose, the best string off.Inner six angle wrench is inserted into the hole at the bottom of the neck Neiqin adjusting holes, clockwise rotation can reduce the chord length, counterclockwise rotation can raise the chord length.

Send your message to us

American Style Heavy Duty Pipe Wrench Plastic Powder Spray-painted

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords