High Pressure Rubber Air Hose High Temperature 3 Steel Layer

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

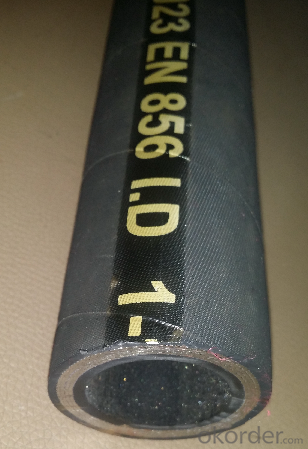

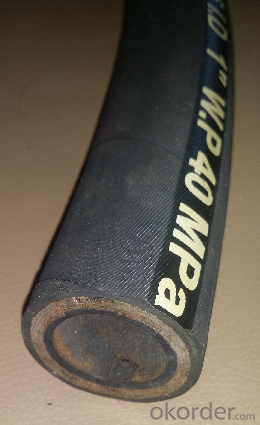

Place of Origin: | Hebei, China (Mainland) | Brand Name: | CMAX | Model Number: | R13 |

Name: | R13 rubber & Hydraulic Hose | Material: | rubber & steel wire | Inner tube: | Nitrile |

Cover: | Black neoprene blend | Reinforcement: | four , six spiralled of high-tensile steel wire | Color: | Black/Red/Green/Yellow |

Temperature range: | -40°Fto 212°F(-40°C-100°C) | Applicable standards: | GB/T 10544 R13, EN 856 R13, SAE J517 R13 | Application: | Used for petroleum and Watrer-based hydraulic fluids |

Factory or not: | Factory |

Packaging & Delivery

Packaging Details: | Spiral hose Plastic packing or according to the customer's requirement |

Delivery Detail: | usually 5-30 days. |

High Pressure/coal/oil Hydraulic Hose

Product Description

Structure

The hydraulic hose consists of an inner tube of liquid resistant synthetic rubber, middle rubber layer, four layers spiral wire reinforcement, and superior weather resistant synthetic rubber cover.

1. Inner Tube: Neoprene

2. Reinforcement: four or six alternating layeers of spiral high tensile steel wire

3. Cover: Black neoprene blend that meets MT98 and GB/T 15907 Flame resistance

4. Application Standards: GB/T 10544 R13, EN 856 R13, MT98 R13.

Application

hydraulic hose is a medium pressure hose that can be used in mobile, machine tool, agricultural application and other hydraulic systems.

It can also be used in conveying petroleum or water based hydraulic fluids which under specific pressure and temperature.

Working Temperature : Oil: -40°C to +100°C, Air: -30°C to 50°C, Water Emulsion under +80°C

Features

1. It provides superior oil resistance, heat resistance and aging resistance by using special synthetic rubber.

2. It provides high pressure resistance and superior impulse resistance.

3. It provides superior bonding in hose internal, soft use and small deformation under pressure.

4. It provides superior kink resistance and fatigue resistance and longer services life.

FAQ

Q1. Do you produce smooth or cloth wrapped cover?

1. A. Both, we can produce both cover, which depends on customer’s request.

Q2. Do you produce embossed marking?

1. A. Yes, we do provide embossed and printing markings with different color.

Q3. Can you produce product with my own brand?

1. A. Yes, we have been offering OEM services for 20 years.

Q4. Does your product have different color hose?

1. A. Yes, we currently provide black, grey, red, blue and yellow.

Q5. How long does my order take to be delivered?

1. A. It usually takes 5 to 30 days, which generally depends on the quantity of your order and our storage.

- Q: What is the function between the rubber pipe joint and the installing pipe?

- The action of the rubber pipe joint on the installation of pipes:1. Small size, light weight, good elasticity, easy installation and maintenance.2. After installation, the transverse, axial and angular displacement of the pipe vibration can be absorbed. The pipe is not concentric and the flange is not parallel.3 、 after installation, it can reduce the noise caused by vibration of pipes, pumps and so on, and has strong vibration absorption ability.

- Q: The difference between the rubber pipe and PE pipe

- PE is the most basic plastic of polyethylene plastics, plastic bags, plastic film and so on are PE, HDPE is a high crystallinity, non-polar thermoplastic resin. The appearance of the native HDPE is milky white and is somewhat translucent in the narrow cross section.

- Q: What is a rubber core pulling method?

- The hose shall be filled with water or gas at a pressure of 0.5 0.8N / mm before pouring concrete. At this point, the hose diameter can be increased by about 3mm. When pouring concrete, the vibrating bar should not touch the hose, and should check the pressure of the water meter regularly. If there is any change, the pressure must be filled.Smoke tube longer than tube core pulling slightly later. Before the pipe is pumped, the water is lowered and the pipe section is reduced, and the pipe can be drawn away from the concrete. The order of pumping is usually first, then first, then first, then straight.

- Q: The engine cylinder head cover behind the drop rubber tube what reason (Xichai 490 engine) (note the valve chamber cover tube)

- The valve chamber of the engine cylinder head cover counterclockwise with 8~10 open wrench counterclockwise unscrew rocker screw. Place the piston at the top dead center, turn the rocker head wire clockwise until the hand can not be moved, then back half a circle, then lock the nut.

- Q: Can the rubber hose for the LPG cooker and gas cooker be general?

- The rubber hose for the gas cooker and the gas cooker can be used as long as the size is the same.

- Q: What are the types of cable metal hose connections?

- The utility model is mainly used for connecting the metal hose and the steel pipe, and the installation of the clamping sleeve is not required to be sheathed on the steel pipe

- Q: Which is better for binding files with rubber tubes and cotton threads?

- In fact, the most suitable binding file is the file department I twine, such units are preserved, just to have you asked, hope to adopt

- Q: High pressure hose crimping connector, pressed on what position can effectively prevent the head off?

- If the withholding at the blasting, the main reason is the hose and the joint has not reached the best fit, in the areas of improvement should be mainly in joint selection and press on.

- Q: Do you know the inner diameter of the hose for household shower hose is the same? Can different brands of shower and hose mix?

- The shower hose interface is the same, 4 interface is Water Leakage washer, and shower hose can be mixed, Plumbing Hardware stores generally have washer, preferably with silicone rubber, durable, no, poor quality

- Q: The rubber is sheathed on the metal cylinder. How can it be connected?

- If you describe it, it is recommended that a soft binder such as 704 silicone gel will be used to prevent shock absorption and separation. Metal surface to rust treatment, clean can be coated adhesive, rubber cover surface is best polished, degreasing treatment effect is good!

Send your message to us

High Pressure Rubber Air Hose High Temperature 3 Steel Layer

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords