Raw Materials for Refractory:High Grade Refractory Material/SiC Powder - Black Silicon Carbide 97

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 150000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Grade Refractory Material/SiC Powder--Black Silicon Carbide 97

1.Structure of Silicon Carbide Description

Black Silicon Carbide is produced with high temperature in a electric resistant furnace from a mixture of quartz sand and petroleum coke.

Black silicon carbide is typically used for working on cast iron ,non-ferrous metals, stone, leather, rubber, and other materials which requires sharp cutting characteristics. The mineral is also used widely as a refractory material and metallurgical additive.

2.Main Features of Silicon Carbide

Its hardness is between that of fused alumina and synthetic diamond and mechancial intensity of it is also greater than that of fused alumina. It is brittle and very sharp and has a certain degree of electrical and heat conductivity.

3.Main usage of the Silicon Carbide

1.Grinding non-ferrous materials, rock, stone, leather, rubber, finishing tough and hard materials

2.Bonded abrasive tools, lapping and polishing

3.Widely used as a metallurgical additive and refractory material

4.Refractory

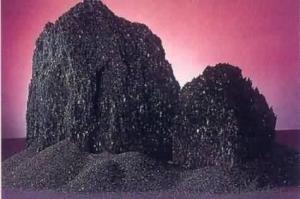

4. Silicon Carbide Images

5.FAQ of Silicon Carbide

1). Q: Are you a factory or trading company?

A: We are a factory.

2). Q: Where is your factory located? How can I visit there?

A: Our factory is located in Ningxia, China. You are warmly welcomed to visit us!

3). Q: How can I get some samples?

A: Please contact me for samples

- Q: A chemical problem with refractory materials

- No, in junior high school may be exposed to AlN aluminum nitride, high temperature resistant new ceramic, water will react...

- Q: Who knows about the fire endurance of A grade fireproofing glass doors?

- The fire endurance of grade A fire resistance rolling shutter doors should be no less than three hours. Fire doors can be divided into A, B and C grades according to their fire endurance which should be no less than 1.20 h, 0.90 h and 0.60h respectively. Places where are difficult to set fire-proof bulkheads can use fire resisting shutters as partitions of fire?compartments. The fire endurance of fire resisting shutters that include unexposed surface temperature rise as judging condition should be no less than 3 h. Fire resisting shutters that exclude unexposed surface temperature rise as judging condition should set up independent protection of closed automatic water spray system on both sides of shutters, and the duration of water spray system should be no less than 3.0 h.

- Q: What is the function of refractory in ceramics?

- Refractory is used as materials of kiln,sagger and kiln car for ceramic sintering. Its refractoriness is higher than ceramics, and the essential material and tool for ceramic sintering.

- Q: The difference between refractory and thermal insulation material

- Refractory refers to inorganic non-metallic material, whose refractoriness is not less than 1,580℃, but refractory is not necessarily insulated material. Inorganic thermal insulated material also belongs to refractory as long as its refractoriness is higher than 1,580℃.

- Q: What things and cement mixed can act as refractory?

- Cement building, portland cement, refractory grade, calcium aluminate. Cement acts as refractory need to use calcium aluminate cement.

- Q: What's the refractoriness and how to measure the refractoriness?

- Bottom each side length is 8 mm and upper side length is 2 mm. Under a certain temperature-rising speed, when heating, refractory's resistance to high temperature from melting is called refractoriness. The properties of cross section into an equilateral triangle and height is 30 mm. When it bends down until the vertex and chassis contact temperature is the refractoriness of sample. It bends due to the influence of its weight. Make the will-measured material into standard pyrometric cone.

- Q: How many types of fire-resistant material?

- 1. Acid fire-resistant material refers to one with more than 93% SiO2. It is featured by resistance to the corrosion of acidic slag ad high temperature and easy to react with alkaline molten slag. 2. Alkaline refractory material generally refers to one with magnesium oxide or magnesium oxide and calcium oxide as the main component. It has high refractoriness and strong resistance to basic slag. 3. Silicate aluminum refractory material refers to one with SiO2, Al2O3 as the main component. According to the content of Al2O, it can be divided into three categories: half siliceous (15-30% Al2O3), clay (Al2O3 30 ~ 48%), high aluminum (more than 48% of Al2O3). 4. Fused cast refractory material refers to shaped refractory products made by high temperature melting and casting.

- Q: What kind of materials are needed to make refractory bricks?

- Refractory materials generally refer to inorganic non-metallic materials with fire resistance above 1580℃. It plays an important role in metallurgy, nonferrous metals, chemical engineering, ceramics, and industrial production. Different industry needs different materials. You can turn to the knowledgeable internet.

- Q: Introduction to refractory material

- Refractory material refers to inorganic non-metallic materials with refractoriness of no less than 1580℃. Refractoriness refers to the centigrade temperature of refractory cone sample in the case of no load when resisting high temperature without softening. But the refractoriness alone cannot descript the refractory material, thus 1580℃ is not absolute. Now refractory material is defined as material used in high temperature allowed by its chemical properties. Refractory material is widely used in metallurgy, chemical industry, petroleum, machinery manufacturing, silicate and power industrial area, of which the application in metallurgy accounts for the largest part of 50% ~ 60% of total output.

Send your message to us

Raw Materials for Refractory:High Grade Refractory Material/SiC Powder - Black Silicon Carbide 97

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 150000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords