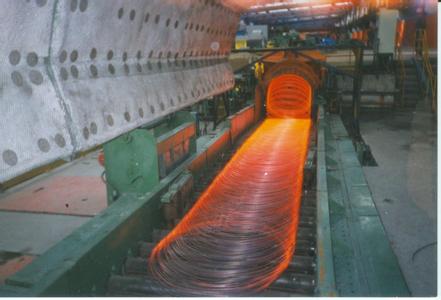

High grade hot-finished rod

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Wire is 5-22 mm diameter hot rolled round steel, or rather the cross section of special-shaped steel. Due to the delivery of the goods in the form of wire rod, so it is also known as wire rod.

Wire cross-section circumference is small, common specifications for 5-13 mm diameter. According to the different can be divided into the high speed wire rod mill (line) and ordinary wire line (at) two kinds.

Generally made from ordinary carbon steel and high quality carbon steel wire rod. According to the directory and USES different steel distribution, mild steel wire including ordinary hot rolled plate, the high quality carbon steel wire rod, carbon electrode wire rod, conditioning threaded rod, wire rope with wire rod, piano wire with wire rod and stainless steel wire rod, etc.

1. Ordinary low carbon steel hot rolled plate (GB701-65), normal low carbon steel hot rolled plate by low carbon ordinary carbon structural steel or the carbon structural steel rolling of low yield point, is dosage the biggest, the most widely used in varieties of wire rod, also known as the cord.

Main use: general line is mainly used in construction of reinforced concrete structure for reinforcement, can also be made steel wire, cold drawn to pull for strapping, etc.

2. Ordinary no twist accused of cold, hot rolled low carbon steel wire rod (ZBH4403-88), no twist accused of cold, hot-rolled wire rod by no twist to control cooling after rolling in high speed wire-rod mill, material is the same as the general line, but no twist accused of cold, hot-rolled wire rod with high dimensional accuracy, good surface quality and higher mechanical properties, etc.

Main application: no twist accuracy of cold, hot-rolled wire rod size control points A, B, C level 3. A, B, C level precision is applicable to drawing, construction, packaging and electrode and other purposes, B, C level accuracy is suitable for processing into bolts, screws and nuts, etc.

3. Quality carbon steel wire rod (GB4354-84), high quality carbon steel wire rod is made of high quality carbon structural steel rolling. Is one dosage larger varieties of wire rod variety.

Main application: high quality carbon steel wire rod is mainly used for processing and manufacturing carbon spring steel wire, oil quenching tempering carbon spring steel wire, prestressed steel wire, high strength and high quality carbon structural steel wire, galvanized steel wire, galvanized wire rope, etc.

4. Quality carbon steel no twist accused of cold, hot-rolled wire rod (ZBH44002-88), no twist accused of cold, hot-rolled wire rod quality carbon steel by the high-speed wire mill rolling with no twist, disposed of by controlled cooling after rolling. Compared with the high quality carbon steel wire rod, high dimensional accuracy, good surface quality, have higher mechanical properties.

Main USES: the main purpose is the same as the high quality carbon steel wire rod. Often used in the manufacture of carbon spring steel wire, oil quenching tempering carbon spring steel wire, prestressed steel wire, high quality carbon structural steel wire, galvanized steel wire, etc.

5. Wire rope with wire rod (YB349-64), wire rope with wire rod is one of the high quality carbon structural steel hot rolled plate.

Main application: wire rope with wire rod available 35 and 40, 45, 55, 60, 65, 70, 75, 80 and 85 steel grade high quality carbon structural steel manufacture. Chemical composition meet GB699 (high quality carbon structural steel technical conditions).

6. Wire rope with no twist accused of cold, hot-rolled wire rod (ZBH44004-88), wire rope with no twist charged with hot and cold rolled plate and with high quality carbon structural steel, in the absence of torsion wire mill rolling, controlled cooling after rolling. This rolling of wire rod, high dimensional accuracy, good surface quality, superior mechanical properties.

Main application: mainly used for drawing steel and steel strand steel wire rope.

7. Carbon electrode steel wire rod (GB3429-82), carbon electrode made by high quality carbon structural steel hot rolled low carbon steel rod.

Main application: mainly used in the manufacture of manual arc welding welding core.

8. No twist accused of cold, hot rolled carbon electrode steel wire rod (ZBH44005-88), no twist accused of cold, hot rolled carbon electrode steel wire rod is rolling on blockade twist wire mill, and made controlled cooling after rolling. Its high dimensional accuracy, good surface quality, superior performance, is a kind of high quality welding rod steel wire rod.

Main application: mainly used in the manufacture of a coated electrode steel reinforced carbon steel hot rolled plate.

9. Alloy structural steel hot-rolled wire rod (GB3077-82), alloy structural steel hot-rolled wire rod by alloy structural steel rolling material. Alloy structural steel with a total of 26 steel group, the 78 steel grades. Each manufacturer according to buyer's requirements and different USES to choose brand for production.

Main use: alloy hot rolled wire rod structure is mainly used for drawing wire, metal products and components.

10. Carbon tool steel hot-rolled wire rod (GB1298-86), carbon tool steel by high quality or high quality high carbon steel rolling. Processing performance and wear-resisting performance is good, the price is cheap.

Main USES: mainly used in drawn steel ratio and making tools, etc.

11. Alloy tool steel hot-rolled wire rod (GB1299-77)

Alloy tool steels is in chrome is joined on the matrix carbon tool steel, tungsten, molybdenum, vanadium, silicon, manganese, nickel and cobalt alloy elements and tempered steel. Compared with the carbon tool steel. It has good hardenability, small heat cracking tendency, the characteristics of high wear resistance and heat resistance. Alloy tool steel hot-rolled wire rod by 33 five steel group steel grade of alloy tool steel material and rolled. Respectively by the dalian steel, benxi steel mills and steel mills and other unit production in shaanxi province.

Main use: is suitable for measuring tool, cutting tool and cold and hot die, shock resistant, etc.

12. Spring steel hot-rolled wire rod (GB1222-84)

Spring steel is used in the manufacture of springs or other steel grade of elastic element. Springs and elastic element mainly USES the elastic degeneration absorb and store energy, alleviate vibration, shock, or make parts to complete some action for the purpose. Since it is in shock, vibration or even under the working conditions of periodic alternating stress for a long time, so the spring steel with high yield strength, especially must have higher showed (the ratio of yield strength to tensile strength) and fatigue strength of high elastic, high resistance to high temperature and corrosion resistant performance. The surface of spring steel shall also have the good quality.

Spring steel with carbon spring steel and alloy spring steel, a total of 17 brands.

Main use: spring steel hot-rolled wire rod is mainly used in the production of various USES of helical spring.

13. Ball bearing steel hot-rolled wire rod (YB9-68), referred to as "bearing steel, ball bearing steel is used in the manufacture of various types of rolling bearing ring (sleeve) and steel rolling body (the ball). Due to the particularity of its USES for bearing steel has high and even hardness and wear resistance, high elasticity and fatigue strength. Enough toughness and hardenability, at the same time in the atmospheric environment or lubricant has certain corrosion resistant ability. Some special use of the rolling bearing also require high temperature resistance, corrosion resistance, nonmagnetic, ultra-low temperature, high precision, long life and other performance. So the choice of bearing steel and steel than ordinary steel strict quality.

Bearing steel is usually refers to the high carbon chromium steel, there are also carburizing bearing steel, high carbon chromium stainless bearing steel. Commonly used in rolling bearing steel hot-rolled wire rod steel grade five.

Main use: ball bearing steel hot-rolled wire rod is mainly used in the manufacture of bearing steel ball (ball), etc.

14. Stainless steel wire rod (GB4356-84), stainless steel wire rod was organized by a variety of brand different size of stainless steel hot rolling.

Main use: stainless steel wire rod is mainly used in the manufacture of stainless steel wire, stainless spring steel wire, stainless wire upsetting and stainless steel wire. According to the main industrial USES for to distinguish, stainless steel wire rod are stainless steel and stainless acid-resistant steel wire rod.

15. Welding of stainless steel wire rod (GB4241-84), welding of stainless steel wire rod and stainless steel wire rod is different in chemical composition. In order to guarantee its excellent welding performance, improve the quality of weld, welding of stainless steel wire rod in composition marked characteristics are low carbon, phosphorus, sulfur, less toxic impurities, such as nickel, chromium content is higher.

Main application: mainly used in the manufacture of welding electrode wire and steel core.

- Q: What are the common material specifications for steel wire rod?

- The common material specifications for steel wire rod are typically determined by the specific requirements of the industry or application in which the wire rod will be used. However, there are some general material specifications that are commonly found in steel wire rod. One of the most important material specifications for steel wire rod is its chemical composition. Steel wire rod is typically made from carbon steel, which contains varying amounts of carbon and other alloying elements such as manganese, silicon, and sulfur. The exact composition of the steel wire rod will depend on the desired mechanical properties and the intended application. Another important material specification for steel wire rod is its size and shape. Steel wire rod is generally produced in coils with diameters ranging from a few millimeters to several centimeters. The specific size and shape of the wire rod will depend on the requirements of the end product, such as the desired strength, flexibility, and conductivity. Furthermore, the mechanical properties of the steel wire rod are also specified. These properties include the tensile strength, yield strength, and elongation, which determine the wire rod's ability to withstand forces and deformations without breaking. The mechanical properties are typically achieved through specific manufacturing processes and heat treatments. Other common material specifications for steel wire rod may include surface quality requirements, such as smoothness, cleanliness, and absence of defects. Additionally, certain industries or applications may have specific requirements for corrosion resistance, electrical conductivity, or thermal conductivity, which would also be specified. It is important to note that the exact material specifications for steel wire rod can vary significantly depending on the specific industry or application. Therefore, it is crucial to carefully review the requirements and consult industry standards or experts to ensure the appropriate material specifications are met for the intended use of the steel wire rod.

- Q: How does the fatigue strength of steel wire rod vary with different wire drawing processes?

- The fatigue strength of steel wire rod can vary with different wire drawing processes. The fatigue strength generally increases with the reduction in wire diameter achieved through wire drawing. This is because the wire drawing process helps to align the grain structure of the steel wire, leading to improved mechanical properties and increased resistance to fatigue failure. Additionally, the wire drawing process can also eliminate surface defects and impurities, further enhancing the fatigue strength of the steel wire rod.

- Q: How is steel wire rod used in the production of conveyor belts?

- Conveyor belts rely heavily on steel wire rod, an essential component in their manufacturing process. Its primary function is to reinforce and strengthen the structure of conveyor belts, ensuring their durability and reliability. To create conveyor belts, steel wire rod undergoes a series of mechanical processes, including hot rolling, cold drawing, and annealing, to transform it into thin, elongated wires. These wires are then twisted and braided together, forming a robust and flexible steel cord. The steel cord is embedded within the core of the conveyor belt, providing exceptional tensile strength and resistance to stretching. This reinforcement allows conveyor belts to bear heavy loads and endure high tension without breaking or deforming. Furthermore, the steel cord enhances the conveyor belt's ability to withstand impact, abrasion, and tearing. Aside from their structural advantages, steel wire rods used in conveyor belts offer additional benefits. They possess high thermal stability, ensuring that the conveyor belt can operate safely even in extreme temperatures. Additionally, the steel cord is highly resistant to corrosion, preventing premature deterioration of the conveyor belt. Overall, steel wire rod plays a vital role in the production of conveyor belts, furnishing the necessary strength and durability for efficient operation. It guarantees that conveyor belts can transport materials smoothly and reliably across various industries, such as mining, manufacturing, and logistics.

- Q: How is steel wire rod used in the production of wire mesh for filtration?

- Steel wire rod is an essential component in the production of wire mesh for filtration as it is used to create the individual wires that are woven or welded together to form the mesh. The wire rod is drawn or rolled to the desired diameter, and then it undergoes various processes to ensure its strength and durability. These wires are then woven or welded together in a specific pattern to create the wire mesh, which is widely used in filtration applications to effectively separate solids from liquids or gases.

- Q: What are the different types of steel wire rod coatings used for high-temperature resistance?

- There are several types of steel wire rod coatings that are used for high-temperature resistance. These coatings are designed to protect the steel wire rod from oxidation, corrosion, and other forms of damage that can occur at elevated temperatures. One common type of coating used for high-temperature resistance is zinc. Zinc coatings provide excellent corrosion protection at high temperatures and are often used in applications where the steel wire rod will be exposed to extreme heat. Another type of coating that is commonly used for high-temperature resistance is aluminum. Aluminum coatings can withstand high temperatures and provide a barrier against oxidation and corrosion. Additionally, there are specialized coatings that are specifically designed for high-temperature resistance. These coatings often contain materials such as ceramic, refractory metals, or silicone-based compounds. Ceramic coatings, for example, are known for their ability to withstand extremely high temperatures and provide excellent thermal insulation. Refractory metal coatings, such as tungsten or molybdenum, are used in applications where the steel wire rod will be exposed to extremely high temperatures and harsh environments. Silicone-based coatings are known for their heat resistance and can provide a protective barrier against oxidation and corrosion. The choice of coating depends on the specific application and the desired level of high-temperature resistance. It is important to consider factors such as the operating temperature, the environment, and the level of protection required when selecting a coating for steel wire rod used in high-temperature applications.

- Q: What are the different types of steel wire rod surface defect monitoring and reporting systems?

- There are various types of steel wire rod surface defect monitoring and reporting systems, including visual inspection systems, automated optical inspection systems, ultrasonic inspection systems, and electromagnetic inspection systems. These systems utilize different technologies and methods to detect and analyze surface defects on steel wire rods, providing accurate and detailed reports for quality control and process improvement purposes.

- Q: What are the environmental considerations of steel wire rod production?

- The environmental considerations of steel wire rod production include the extraction and processing of raw materials, such as iron ore and coal, which can contribute to habitat destruction and greenhouse gas emissions. The energy-intensive manufacturing process can also generate air and water pollution, as well as waste materials that require proper disposal. Additionally, the transportation of steel wire rods adds to carbon emissions. However, efforts are being made to reduce the environmental impact through the use of more sustainable practices, such as recycling steel scrap and implementing cleaner production technologies.

- Q: What are the different sizes and dimensions of steel wire rod?

- Steel wire rods come in various sizes and dimensions to cater to different industrial and commercial applications. The sizes and dimensions of steel wire rods are typically determined by their intended use and manufacturing standards. The diameter of steel wire rods can range from as small as 0.1 millimeters (mm) to as large as 60 mm or more. The most common sizes available in the market are typically between 5 mm and 20 mm in diameter. However, specialized applications may require wire rods with larger or smaller diameters. The length of steel wire rods can vary significantly depending on the requirements. They are often produced in coils, which can range in length from a few meters to several kilometers. The length of wire rods can be customized based on the customer's needs or industry standards. In terms of dimensions, steel wire rods are typically produced in a round shape. However, they can also be manufactured in other shapes such as square, rectangular, or hexagonal, depending on the specific application. The most common shape is round, as it offers excellent strength and flexibility for various uses. Additionally, the weight of steel wire rods can vary depending on the diameter and length. The weight is usually measured in kilograms (kg) or pounds (lb). The weight per unit length is determined by the specific gravity of the steel and the diameter of the wire rod. Overall, the sizes and dimensions of steel wire rods are diverse and can be customized to meet specific requirements. Whether it is for construction, automotive, or other industries, steel wire rods are available in a wide range of sizes to suit various applications.

- Q: What are the different surface defects that can affect the thermal conductivity of steel wire rod?

- Some of the different surface defects that can affect the thermal conductivity of steel wire rod include scales, rust, scratches, pits, and irregularities in the surface texture. These defects can disrupt the smooth flow of thermal energy through the wire rod, reducing its overall thermal conductivity.

- Q: What are the different formability testing methods for steel wire rod?

- Some of the different formability testing methods for steel wire rod include the cupping test, the Erichsen test, the Olsen test, and the Nakajima test. These tests involve subjecting the wire rod to various deformation forces and measuring its ability to withstand and retain its shape.

Send your message to us

High grade hot-finished rod

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords