High Efficiency Silver Polycrystalline Silicon Solar Cells with Stable Performance

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 8000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Polycrystalline Silicon Solar Cells:

Solar cells is made by solar wafer, it has three categories of solar cell right now, monocrystalline polycrystalline and thin film,These cells are entirely based around the concept of ap-n junction, which is the critical part of solar module, it is the part that can convert the light energy into electricity, the thickness is from 180um to 200um, with even busbars to conduct electricity, textured cell can decrease diffuse reflection; they are often electrically connected and encapsulated as a module. Photovoltaic modules often have a sheet of glass on the front (sun up) side, allowing light to pass while protecting semiconductor wafers from abrasion and impact due to wind-driven debris, rain, hail, etc. Solar cells are also usually connected in series in modules, creating an additive voltage. Connecting cells in parallel will yield a higher current;With high quality and stable quality. Our Cells can greatly improve the performance of Solar Modules.

Polycrystalline Silicon Solar Cells Advantage:

• High efficiency and stable performance in photovoltaic conversion.

• Advanced diffusion technique ensuring the homogeneity of energy conversion efficiency of the cell.

• Advanced PECVD film forming, providing a dark blue silicon nitride anti-reflection film of homogenous color and attractive appearance.

• High quality metal paste for back surface and electrode, ensuring good conductivity, high pulling strength and ease of soldering.

• High precision patterning using screen printing, ensuring accurate busbar location for ease with automatic soldering a laser cutting.

Applications of Polycrystalline Solar Cells

Assemblies of photovoltaic cells are used to make solar modules which generate electrical power from sunlight, as distinguished from a "solar module" or "solar panel". A solar array generates solar power using solar energy.

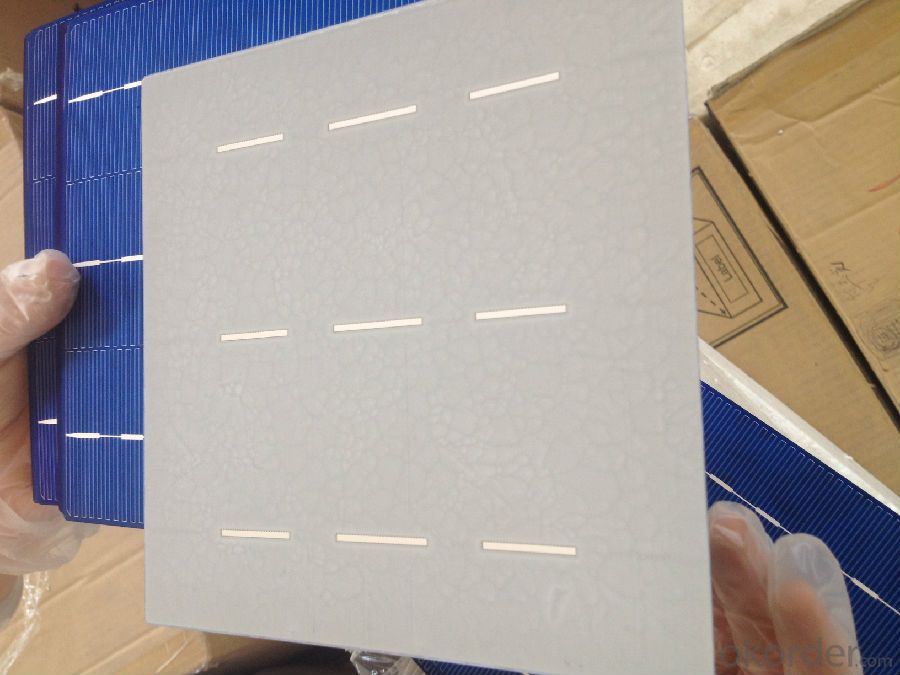

Packaging & Delivery of Polycrystalline Solar Cells

Carton Box Package and Deliver by air. It should be noticed that it should be avoid of water, sunshine and moist.

Specification:

Mechanical data and design |

Format - 156 mm × 156 mm ± 0.5 mm |

Thickness- - 200 μm ± 20 μm |

Front (-) - 1.4 mm bus bars (silver),blue anti-reflection coating (silicon nitride) |

Back (+) - 2 mm wide soldering pads (silver) back surface field (aluminium) |

Temperature Coefficient of Cells |

Voc. Temp .coef.%/K -0.364%/K |

Isc . Temp .coef.%/K +0.077%/K |

Pm. Temp. coef.%/K -0.368%/K |

Electrical Characteristic |

Efficiency (%) Pmpp (W) Umpp (V) Impp (A) Voc (V) Isc (A) |

18.00% 4.380 0.538 8.141 0.634 8.740 |

17.90% 4.356 0.538 8.097 0.634 8.725 |

17.80% 4.331 0.537 8.065 0.633 8.710 |

17.70% 4.307 0.536 8.035 0.632 8.695 |

17.60% 4.283 0.535 8.006 0.631 8.680 |

17.50% 4.258 0.534 7.974 0.630 8.665 |

17.40% 4.234 0.533 7.944 0.629 8.650 |

17.30% 4.210 0.532 7.914 0.628 8.635 |

17.20% 4.185 0.531 7.88 -- 0.627 -- 8.620 |

17.10% 4.161 0.530 7.851 0.626 8.605 |

17.00% 4.137 0.529 7.820 0.625 8.590 |

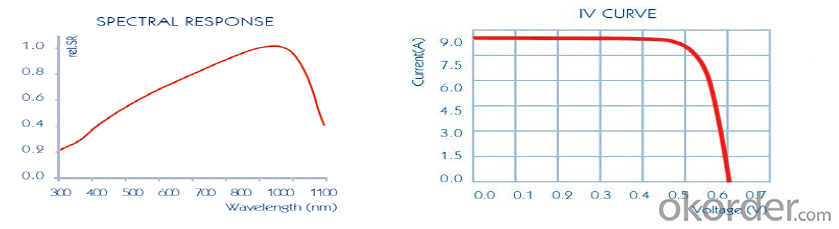

Intensity Dependence |

Intensity [W/m2] Isc× [mA] Voc× [mV] Pmpp |

1000 1.00 1.000 1.00 |

900 0.90 1.000 0.90 |

800 0.80 0.99 0.80 |

500 0.50 0.96 0.49 |

300 0.30 0.93 0.29 |

200 0.20 0.92 0.19 |

IV Curve

Solar Panel Images:

FAQ

We have organized several common questions for our clients,may help you sincerely:

①What price for each watt?

It depends on the efficiency of the solar cell, quantity, delivery date and payment terms.

②How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

③Can you provide the peripheral products of the solar panels, such as the battery, controller, and inverter? If so, can you tell me how do they match each other?

Yes, we can, we have two companies for solar region, one is CNBM International, the other is CNBM engineering Co.

We can provide you not only the solar module but also the off grid solar system, we can also provide you service with on grid plant.

④What is your warranty of solar cell?

Our product can promise lower than 0.3% open box crack, we support claim after opening the box if it has crackm color difference or sth, the buyer should give pictures immediately, we can not accept the claim after the solar cell has assembled to solar panel.

• Timeliness of delivery

• ⑤How do you pack your products?

We have rich experience on how to pack the solar cell to make sure the safety on shipment, we could use wooden box or pallet as buyer's preference.

⑥ Can you do OEM for us?

Yes, we can.

Points to note when buy solar cells

Since the input of solar energy photovoltaic power generation system is unstable, it is generally required to configure the battery system to work, and solar lighting is no exception which you must configure the battery to work. Generally three are lead-acid batteries, Ni-Cd batteries and Ni-H batteries; their capacity and system reliability selection directly affect the price of the system. Choice of battery capacity generally follow the following principles: First, to meet the night lighting under the premise, as far as possible the energy stored during the day and down the solar cell module, but also capable of storing electrical energy to meet the continuous rainy days night lighting needs. Battery capacity is too small cannot meet the needs of lighting at night; the battery capacity is too large, while the battery is always in the state of power loss, affecting battery life, while wastage.

Select dispensing form when buy solar cells

Currently, there are mainly two kind’s packages of solar cells: Epoxy and laminates. Lamination process ensures that the solar battery life is more than 25 years; though epoxy is beautiful, the solar battery life is only 1 to 2 years. Therefore, 1W power solar lawn below the small, in the absence of the high life requirements of the situation, you can use the dispensing package, there are provisions for the life of the solar light, it is recommended to use laminated package. Further, there is a dispensing package for silicone gel solar cells, the working life of that solar cell is said to be up to 10 years.

Select the power when buy solar cells

Output power WP we mean is the output power of the solar cell under the standard sunlight , 101 standard, radiation intensity 1000W / m2, the air quality of AM1.5, cell temperature 25 ℃ conditions, which is by the European Commission. This condition is probably the same conditions with the usual sunlight sunny around noon, which is not, as some people imagine that kind, as long as the sun will have a rated output power, even at night that the solar lamp can be used normally. That is to say, the solar cell output power is random, at different times, different locations, also a solar cell output power is different. When people buy solar lights, in between aesthetics and energy, most of them choose energy-saving.

- Q: Can solar cells be used on airplanes?

- Yes, solar cells can be used on airplanes. Solar panels can be installed on the wings or fuselage of an aircraft to harness solar energy and convert it into electricity. This can be used to power various onboard systems, reduce reliance on traditional fuel sources, and increase the overall energy efficiency of the aircraft.

- Q: Can solar cells be used for powering remote communication towers?

- Yes, solar cells can be used to power remote communication towers. Solar panels can be installed on the towers or nearby to capture sunlight and convert it into electricity. This renewable energy source is ideal for remote locations where access to traditional power grids may be limited or costly. Solar cells can provide a reliable and sustainable power supply for remote communication towers, enabling them to function efficiently.

- Q: What are the environmental impacts of solar cell production?

- The environmental impacts of solar cell production include the extraction of raw materials, such as silicon, which can contribute to deforestation and habitat destruction. The manufacturing process also requires a significant amount of energy, which may be sourced from fossil fuels and contribute to greenhouse gas emissions. Additionally, the disposal and recycling of solar panels can pose challenges, as some components contain harmful substances. However, it is important to note that the overall environmental benefits of solar energy, such as reduced greenhouse gas emissions and reliance on fossil fuels, outweigh these impacts.

- Q: Can solar cells be damaged by hail or other weather conditions?

- Yes, solar cells can be damaged by hail or other severe weather conditions. Hailstones can cause physical damage to the surface of solar panels, resulting in cracks or fractures that may affect their efficiency. Additionally, extreme weather events such as heavy rain, strong winds, or lightning storms can potentially cause electrical and structural damage to solar cell systems. Hence, it is important to consider the durability and resilience of solar panels when installing them in areas prone to such weather conditions.

- Q: Can solar cells be used to power large-scale industrial facilities?

- Yes, solar cells can indeed be used to power large-scale industrial facilities. With advancements in solar technology and the availability of more efficient and cost-effective solar panels, industrial facilities can harness the power of the sun to meet their energy needs. Large-scale solar installations, such as solar farms or rooftop arrays, can generate substantial amounts of electricity, making them a viable option for powering industrial operations. Additionally, integrating solar power into industrial facilities can reduce greenhouse gas emissions, lower energy costs, and provide a more sustainable and reliable energy source.

- Q: Can solar cells be used in mining operations?

- Yes, solar cells can be used in mining operations. They can provide a sustainable and cost-effective source of energy for various mining activities, such as powering equipment, lighting, and ventilation systems. Additionally, solar cells can be integrated with energy storage solutions to ensure uninterrupted power supply, even in remote mining locations. By using solar cells, mining operations can reduce their reliance on fossil fuels, decrease their carbon footprint, and contribute to a more sustainable mining industry.

- Q: I am working on research for the usage of solar cells, where can I find more news of solar cells?

- You can try Phys.org, who provides the latest news on science including: Physics, Space Science, Earth Science, Health and Medicine.

- Q: How do solar cells perform in high humidity environments?

- Solar cells typically perform well in high humidity environments. However, excessive moisture or prolonged exposure to water can lead to a decrease in their efficiency. It is important to ensure proper waterproofing and maintenance of the solar panels to prevent any potential damage caused by moisture.

- Q: How are solar cells used in agricultural applications?

- Solar cells are used in agricultural applications to generate electricity for various purposes, such as powering irrigation systems, lighting in greenhouses, and running equipment like pumps and fans. They help farmers reduce their reliance on traditional energy sources and promote sustainable farming practices.

- Q: Where can I buy solar cells on sale but still good quality ?

- This is what I found on alibaba, The solar cells for Sale are 40 NEW, solar cells that are 3"x 6" each. PLUS Tabbing, Bus, Flux and a Diode. Great experience to build your own solar panel and save a lot of money.

Send your message to us

High Efficiency Silver Polycrystalline Silicon Solar Cells with Stable Performance

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 8000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords