High Efficiency Plywood Sheets for Formwork System Assembly

- Loading Port:

- Shekou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m³

- Supply Capability:

- 6000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

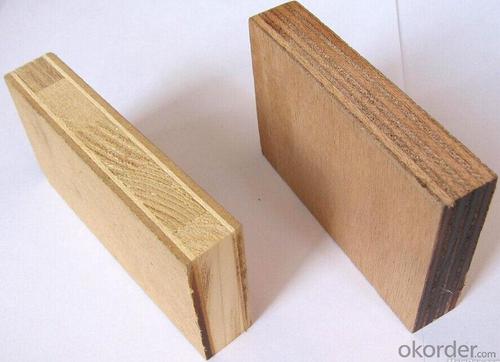

Plywood Introduction :

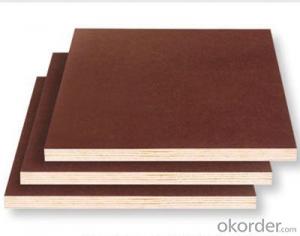

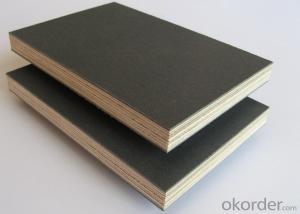

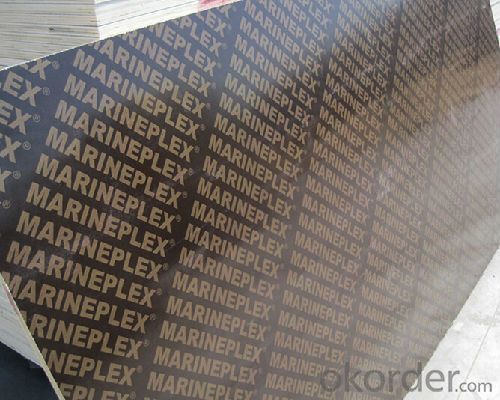

Plywood is with film faced , it is widely used in construction formwork system , it is the direct close with concrete .To make sure flat concrete surface, we ask the plywood better surface and long using lifetime .It can be with brown film and black film and plastic film.

Feature:

1.High bending strength

2.Strong nail holding

3.Moisture-proof and easy work

4.Tight construction and high strength

Specification:

Film | Chinese film 180-240g/m2 | |

Core | birch,poplar, hardwood ,combined or others | |

Grade | A/A or requested by customers | |

Glue | WBP,MR,Melamine(waterproof) | |

Size(mm) | 2440X1220, 2500X1250, 3000x1500 | |

Thickness(mm) | 6-27mm | 1/4inch(6-6.5mm) |

1/2inch(12-12.7mm) | ||

5/8inch(15-16mm) | ||

3/4inch(18-19mm) | ||

Moisture | ≤10% | |

Thickness tolerance | ≤ 6mm | +/-0.2mm to 0.3mm |

6-27mm | +/- 0.5mm | |

Packing | For transportation of Ocean and Land, Inside Pallet is wrapped with 0.2mm plastic bag, Steel strip or PVC for strength, More than 2mm plywood sheet or hard paper covering all the sides left, right,top and bottom. | |

Quantity | 20GP | 8 pallets/21M3 |

40GP | 16 pallets/42M3 | |

40HC | 18 pallets/53M3 | |

Usage | Usage Adequate for concrete forming for construction | |

Min Order | 1x20'ft container | |

Payment | T/T or L/C at sight | |

Delivery time | Within 20days after receiving deposit or Original L/C at sight | |

- Q: Plywood in the material defects?

- Abnormal structure Any defects caused by abnormal wood construction, such as wrinkles. Wavy pattern. Staggered pattern, spiral pattern and so on.

- Q: according to the use of plywood can be divided into needle plywood and broadleaf plywood.

- the minimum number of layers of each nominal thickness to comply with the relevant provisions.

- Q: What are the further processing of plywood?

- plywood plywood through mechanical finishing or gluing, such as cutting, profiling sawing, hitting, drilling, milling and other processed plywood

- Q: A brief introduction to plywood

- Commonly used plywood type plywood, penta and so on. Plywood can improve timber utilization and is a major way to save wood.

- Q: What are the processing defects of plywood?

- Warping warPing is generally a regular deformation, part or all of the surface of the plywood is curved.

- Q: Plywood in the decoration works how to use

- The number of layers is generally odd, and few are even. Vertical and horizontal direction of the physical and mechanical properties of small differences.

- Q: Material for the plywood defects which

- false heartwood heartwood sound wood center part of the color is different from the normal wood, often dark brown or reddish-brown, usually its density and hardness are relatively large.

- Q: What are the advantages and disadvantages of plywood?

- Plywood is cut from the wood section into a veneer or cut from the wooden square cut into thin wood

- Q: Plywood quality requirements include appearance level, size, physical and mechanical properties of the three elements.

- Appearance level, size, physical and mechanical properties of the three tests are qualified to determine the product is a qualified product, or judged to be unqualified. P

- Q: What is the plywood made of wood?

- usually with odd-level veneer, and the adjacent layer of veneer Of the fibers are perpendicular to each other.

Send your message to us

High Efficiency Plywood Sheets for Formwork System Assembly

- Loading Port:

- Shekou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m³

- Supply Capability:

- 6000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords