High Alumina Magnesia-MA Spinel Bricks with High Mechanical Strength

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Magnesia-ma Spinel Bricks High Mechanical Strength

Brief discription for magnesia-ma spinel bricks

CMAX magnesia-ma spinel bricks are made by using high quality raw materials, optimized size grading, enforced homogenization, high pressure forming and firing with clean fuel.

CMAX magnesia-ma spinel bricks are mainly used in burning zone, transitional zone of rotary kiln etc.

Advantage for magnesia-ma spinel bricks

◆High refractoriness under load

◆High mechanical strength

◆Excellent thermal shock resistance

◆Corrosion resistance

Technical data for magnesia-ma spinel bricks

ITEM | MA-85A | MA-85B | MA-85C | MA-93A | MA-93B |

MgO,% ≥ | 85 | 82 | 80 | 93 | 90 |

Al2O3,% ≥ | 8 | 8 | 8 | 5 | 5 |

SiO2,% ≤ | 1 | 2 | 3 | 1 | 2 |

Apparent Porosity,% ≤ | 18 | 18 | 19 | 18 | 18 |

Bulk Density, g/cm3 ≥ | 2.95 | 2.9 | 2.85 | 2.95 | 2.9 |

Cold Crushing Strength, Mpa ≥ | 50 | 45 | 40 | 45 | 40 |

Refractoriness Under Load, ℃ ≥ | 1700 | 1700 | 1650 | 1700 | 1700 |

Thermal Shock Resistance< 950℃-Air Quenching, Cycle, ≥ | 120 | 100 | 100 | 100 | 80 |

Thermal Expansion, 1400℃, % | 1.2 | 1.2 | 1.2 | 1.5 | 1.5 |

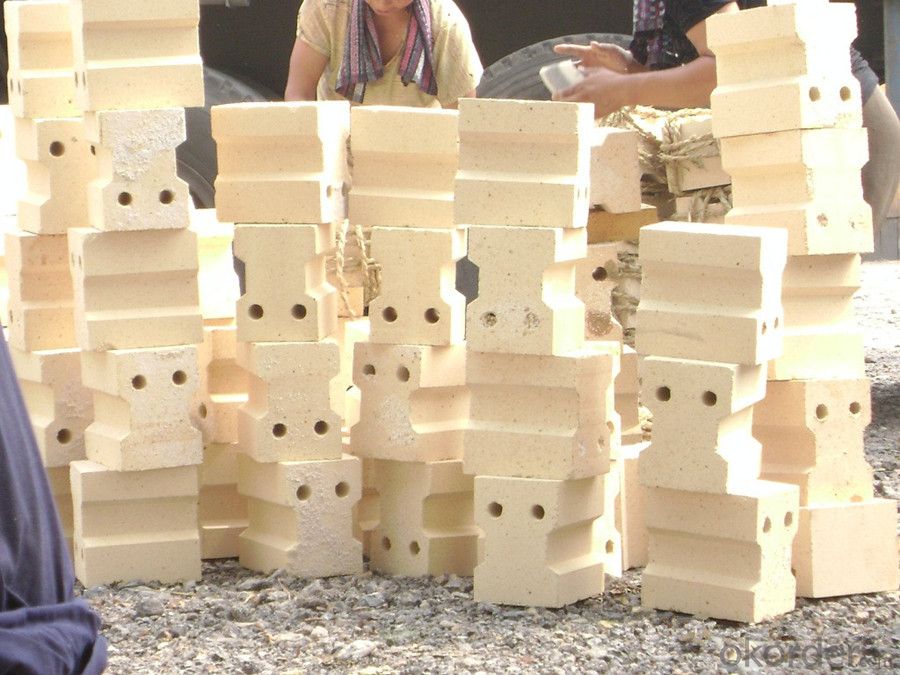

Images/photographs for magnesia-ma spinel bricks

◆ Packaging for Magnesia-ma Spinel Bricks

◆ Producing Equipment for Magnesia-ma Spinel Bricks

◆ Testing Mashines for Magnesia-ma Spinel Bricks

FAQ

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories,at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time,seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Which payment terms can you accept?

A:T/T,L/C are available for us.

Q5:After an order is confirmed,when to deliver?

A:15-25days after deposit.

Q6:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q7:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q8:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q9:Can you offers samples?

A:Of coures,samples are free but freight paid by the buyers.

Q10:What is the service life of your bricks?

A:The service life of different bricks is unlike.It also depends on your using condition and method.

If you have any enquiry,please don't hesitate to contact us,we will provide our best products and services for you!!

- Q: What refractory material does cupola lining use?

- Materials defined as physical and chemical properties that allow them to be used in a high temperature environment are called refractory materials. Refractory materials are widely used in metallurgy, chemical, petroleum, machinery manufacturing, silicate, power and other industrial fields, the largest amount of metallurgical industry, accounting for 50% ~ 60% of the total output.

- Q: Can high alumina brick resist carburizing?

- It is heavy brick mullite brick, brick to do the heavy weight to more than 2.4 manufacturers can achieve a few feeling

- Q: Which is better, the soft core or the hard core?

- The wire has two kinds of hard core and soft core, the hard core line is only one wire core, and the soft core line has a plurality of wire cores. For the same sectional area, the 7 core is more than the more than 30 core. There is a difference in use. Generally used for DC is the use of hard core line, because of its small line consumption; and for communication, we should use soft core line, but also in order to reduce its line consumption

- Q: Corundum, high alumina and fireclay refractory difference is what

- Corundum is unknown. The high alumina brick has higher aluminum content than the clay brick, and the temperature resistance is higher than 300 degrees. It is more durable and durable than the clay brick. The production process of high alumina brick is better than that of clay brick. For example, the weight of good clay brick is 3.7kg, and that of high alumina is 4.2kg. Good density. But the price of high aluminum is too high: ordinary clay brick (standard brick example) in 1.1--2.5 yuan / block, high aluminum to 4.5 yuan / block, or even more expensive. The extra high aluminum has reached 5000 tons. Say straight white point is: under the same conditions, clay brick for a period of one year, then the high aluminum for more than three years.

- Q: What is spalling resistant high alumina brick?

- Spalling resistant high alumina brick is a kind of high alumina brick. Antistripping high alumina brick with high grade bauxite and containing Zr02 synthesis as raw material, according to a certain proportion by high pressure molding system in sintering products, products with anti stripping ability, and have the anti erosion potassium, sodium, sulfur, chlorine and alkali salt, low thermal conductivity and other properties that is the transition zone of cement kiln and decomposition of ideal material with remarkable characteristics, the product is good thermal shock resistance, strong ability to adapt to the environment. It is used in the preheating or decomposing furnace, grate cooler and so on.

- Q: What are ordinary bricks, refractory bricks, hollow bricks?

- Light yellow or brownish. The utility model is mainly used for laying smelting furnaces, and can withstand high temperature between 1580 DEG C and 1770 DEG C. Also called brick. Refractory material of a certain shape and size. According to the preparation process can be divided into bricks, brick, electric melting brick (Rong Zhuzhuan), the refractory insulating bricks; according to the shape and size can be divided into standard brick, brick, brick and other specific type. It can be used as high temperature building materials and structural materials for construction kilns and various thermal equipments, and can undergo various physical, chemical and mechanical changes at high temperature. For example, refractory clay brick, high alumina brick, brick, brick etc..

- Q: The difference between ordinary and diatomite brick refractory brick

- Refractory brick belongs to a large class, according to different materials used are divided into: high alumina brick, dolomite brick, magnesia chrome brick, magnesia spinel brick, phosphate brick, carborundum brick, brick, mullite bricks etc..

- Q: What does refractory consist of?

- Refractory materials can be divided into main raw materials and auxiliary raw materials according to their function in the production process of refractory materials.The main raw material is the main body of refractory. Auxiliary raw materials can be divided into binders and additives. The role of bonding agent is to make the refractory body in the production and use process has enough strength. There are commonly used lignin, phenolic resin, asphalt, cement, water glass, phosphoric acid and phosphate, sulfate, some main raw material itself has the effect of binder, such as clay; additive is to improve the production of refractory materials and construction technology, or strengthen the refractory material of some properties, such as stabilizer, water reducing agent, inhibitor, plasticizer, foaming agent, dispersing agent, bulking agent, antioxidant.

- Q: How to reduce the harm caused by two times mullite in high alumina refractory material

- Two times mullite refers to the content of aluminum is about 70%, in high temperature sintering, the expansion coefficient is large, the thermal expansion rate is high.

- Q: What is the difference between metal compounds and metal solid solutions?

- A series of intermetallic compounds occurring between transition metals in intermetallic compounds. The most important are L sigma sigma phase and ves phase, they are topologically close packed (TcP) phase, they consist of a small atomic radius of a dense layer, which is inlaid with a large atomic radius of atomic structure, this is a highly dense pile. In addition to atomic size factors, their formation is also influenced by the concentration of electrons.

Send your message to us

High Alumina Magnesia-MA Spinel Bricks with High Mechanical Strength

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords