High Alumina Brick for Rotary Kilns

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Alumina Bricks for Rotary Kilns

Composite of High Alumina Bricks

High Alumina Bricks are classified according to alumina content ranging from 48% to 90%.

Main Features of High Alumina Bricks

Low thermal conductivity

Excellent acid and base slagging resistance

High refractoriness

Excellent thermal shock resistance

Excellent mechanical strength

Application of High Alumina Bricks

commonly used in blast furnace, hot blast furnace, the roof of electric furnace, teeming ladle, rotary kiln, regenerator, etc

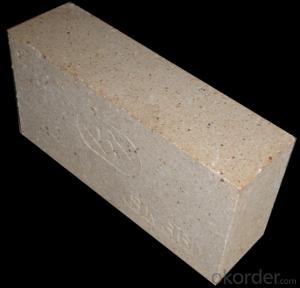

High Alumina Bricks Images

Specification of High Alumina Bricks

HIGH ALUMINA BRICK---ALP85 | |

Apparent Porosity (%) | ≤18 |

Bulk Density (g/cm3) | ≥2.85 |

Cold Crushing Strength (Mpa) | ≥80 |

Modulus Of Rupture (Mpa) | ≥20 |

Refractoriness Under Load (0.2 Mpa)(℃) | 1450 |

Permanent Linear Change (%) | 1500℃×3h -0.5 ~+0.5 |

Chemical Composition (%) |

|

Al2O3 | ≥82 |

Fe2O3 | ≤1.5 |

P2O5 | ≤3 |

FAQ of High Alumina Bricks

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories, at the same time, we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time, seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit, We can offer the best suggestions and solutions according to your condition.

Q4:Which payment terms can you accept?

A:T/T,L/C are available for us.

Q5:After an order is confirmed, when to deliver?

A:15-25days after deposit.

Q6:Is your company accept customization?

A:We have own factory and excellent technical team, and we accept OEM service.

Q7:How about your company's certification?

A:ISO9001 and Test Report, also we could apply other necessary certification.

Q8:How to solve the quality problems?

A:If the products are not confirmed to customer samples or have quality problems, our company will be responsible to make compensation for it.

Q9:Can you offers samples?

A:Of course, samples are free but freight paid by the buyers.

Q10:What is the service life of your bricks?

A:The service life of different bricks is unlike. It also depends on your using condition and method.

- Q: What is fireproof concrete?

- Silicate fireproof heat-resistant concrete using temperature can reach 700 DEG ~800 DEG, the main mechanism of its heat is dehydrated calcium hydroxide silicate hydrates series of cement clinker under high temperature, the calcium oxide and slag and mixing activated silica material in the three and two aluminum oxide and the reaction of anhydrous calcium silicate and anhydrous aluminum acid calcium has strong heat resistance, the fire resistance of concrete is a certain. Such as the use of high alumina bauxite and broken bricks, magnesia brick and magnesia for fireproof heat-resistant concrete materials with the highest using temperature can reach 1100 DEG C.

- Q: In 2016, a few of the traditional refractory materials will be able to survive

- The other is in large enterprises and individual has the unique advantage of the small enterprises, with independent technology system, production equipment advanced, there are certain funds set up to deal with risk, timely reform, such enterprises compared to a few years ago the productivity and sales or have declined, but overall is still in the stage of production increased steadily.

- Q: What is the standard size of high alumina brick?

- Standard brick: 230 x 115 x 65; four points: 230 x 115 x 40; three points: 230 x 115 x 30; 150 x 120: Brick gable. Light weight brick 1 to 1.7 kilograms; heavy clay superscript brick weighs 3.75 kilograms; light 30 plates 0.79 kilograms; light 40 plates, 1.05 kilograms.

- Q: What is the difference between T3 refractory bricks and high alumina refractory bricks?

- The T3 in T3 refractory bricks refers to the model indicating that the refractory brick model is T-3, and that the corresponding T-3 model is 230*114*65 (mm)

- Q: What are the characteristics of high alumina bricks?

- A neutral refractory with an alumina content of more than 48%. Made from alumina or other raw materials of high alumina content; formed and calcined.

- Q: Corundum, high alumina and fireclay refractory difference is what

- They differ in that the alumina content is different, and the content is in order: corundum > high alumina > clay.

- Q: What are ordinary bricks, refractory bricks, hollow bricks?

- Referred to as refractory brick. Refractory wood made from refractory clay or other refractory material

- Q: What is the difference between high alumina brick and clay brick?

- Light clay brick, refractory material is a kind of high porosity, low density, low thermal conductivity of refractory material, refractory materials called lightweight refractories, it includes insulating refractory products, refractory fiber and refractory fiber products. Heat insulation refractory material is characterized by high porosity, general 40%-85%, low volume density, lower than 1.5g/cm3, low thermal conductivity, generally lower than 1.0W (m.K). The utility model has the function of heat insulation of an industrial furnace, and can reduce the heat dissipation loss of the kiln, save energy, and can reduce the quality of the thermal engineering equipment. The mechanical strength, wear resistance and slag resistance of insulating refractory material are poor, and it is not suitable for the load-bearing structure of kiln and direct contact with slag, burden, molten metal and other parts.

- Q: Which thermal shock stability of clay brick and high alumina brick is good?

- The product has the advantages of high temperature, little creep, strong corrosion resistance and good thermal shock resistance, and is suitable for large and medium-sized hot blast stoves.Thermal shock stability is much better than clay brick.

- Q: What is the difference between fireclay bricks and high alumina refractory bricks?

- High R.U.L, low creep high alumina brick [1] is using high grade bauxite, fused corundum, fused mullite as main raw material of high-grade refractory materials. The product has the advantages of high temperature, little creep, strong corrosion resistance and good thermal shock resistance, and is suitable for large and medium-sized hot blast stoves.

Send your message to us

High Alumina Brick for Rotary Kilns

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords