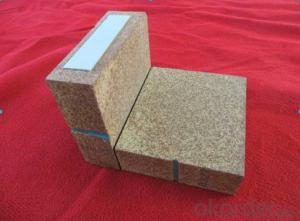

High Alumina Brick by CNBM China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 8000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Gujarat, India | Shape: | Brick | Material: | Alumina Block |

| SiO2 Content (%): | 0.3-15 | Al2O3 Content (%): | 55-95 | Refractoriness (Degree): | Super-Class (Refractoriness> 2000°) |

| Model Number: | GLM-HAB | Brand Name: | CNBM |

Packaging & Delivery

| Packaging Details: | AS PER CLIENTS REQUIREMENT |

| Delivery Detail: | 7-10 DAYS |

applauded for their dimensional stability, compressive strength and durability. Moreover,Super Heat Duty and High Alumina Fire Bricks are the products made from different fractions of refractory grog, fire clays and calcined bauxite of high purity. The different fractions of these raw materials are mixed in counter current mixers and plugged for obtaining homogeneous mixture. The mixture obtained hence, is then pressed in high capacity presses to give the desired shape and size. These pressed shapes are fired in high temperature tunnel kiln at 1300°C and above. These bricks are manufactured as per IS: 6 and IS: 8 specifications and high alumina in the range HEAT 5050 TO HEAT 88 in standard, arch and special shapes.we provide these quality assured bricks to the clients at nominal rates.

- Q: What refractory material does cupola lining use?

- It's made of high quality refractory material: 1770 ~ 2000 centigrade.

- Q: What is the price of the latest thermal insulation material?

- Also through online pre understand the products and prices, and now have large-scale manufacturers are generally opened on the cable business. Goods than three, manufacturers on-site inspection, confirm the quality of goods after considering cooperation.

- Q: What's the difference between a well type annealing furnace and a box type annealing furnace?

- 1. The shell of the furnace is welded by section steel and steel plate. 2, the furnace cover support adopts steel and guide rail combination mobile type. 3. The heating element is made of high resistance alloy 0Cr25Al5 produced by Beijing Shougang Group and arranged on the furnace side. 4, because the bottom bearing adopts high aluminum bricks, the circle center of the furnace set small, inside and outside heating. 5 、 furnace cover adopts hydraulic lifting, motor control, automatic walking. 6 、 temperature control system adopts PID SCR control, high accuracy.

- Q: Density of high alumina bricks

- The density of high alumina bricks is determined according to the price. The average density is between 2.3-2.5g/cm3. The higher the density, the higher the price, the higher the aluminum bricks are in the industry. More than 2.4 are required.

- Q: What's the price of high alumina refractory bricks?

- The price of high alumina refractory bricks varies greatly according to the content of AL2O3.

- Q: What are the alloy wear resistance materials?

- Alloy wear-resistant materials from different manufacturers different components in Beijing Naimo company as an example, the following alloy wear resistant material:1: Ni Cr alloy wear-resistant material2: chrome carbide wear-resistant material3: high manganese alloy wear-resistant material4: tungsten carbide alloy wear-resistant material5: nickel tungsten alloy wear-resistant material

- Q: What are the high temperature refractory mortars made of?

- Siliceous mud, mineral composition and chemical composition is similar with silica, excellent corrosion resistance, water glass slurry, drying shrinkage, but also can be used for bonding fiber products, sealing furnace wall.

- Q: Refractory brick, high alumina brick, magnesia chrome brick, magnesia brick, clay brick, which type of high temperature refractory brick?

- High alumina brick clay brick up to 1700 degrees above 1500 degrees -1750 degrees of magnesia brick and magnesia chrome brick 1500-1650 degrees, I is the production of clay brick, brick my temperature at 1500-1700 degrees. Specific depends on what kiln, brick is only part of it

- Q: What is the difference between metal compounds and metal solid solutions?

- A series of intermetallic compounds occurring between transition metals in intermetallic compounds. The most important are L sigma sigma phase and ves phase, they are topologically close packed (TcP) phase, they consist of a small atomic radius of a dense layer, which is inlaid with a large atomic radius of atomic structure, this is a highly dense pile. In addition to atomic size factors, their formation is also influenced by the concentration of electrons.

- Q: What should be used as binder for making high alumina bricks?

- Bond for making high alumina brick: soft clay has good plasticity, so the high alumina brick is usually made of soft clay as bond. However, the free Al2O3 free SiO2 and bauxite clinker clay in under 1200 degrees occurred two times of Mullization reaction, generate large volume expansion, silicon porosity, strength reduction. Therefore, the amount of clay powder in the ingredient should be no more than 5%.

Send your message to us

High Alumina Brick by CNBM China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 8000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords