High Alumina Brick - Professional Manufacturer for High Alumina Bubble Refractory Bricks

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 8000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Physical and chemical index:

Item | AKZ-85 | AKZ-90 | AKZ-99 | |

Chemical composition | Al2O3 | ≥85 | ≥90 | ≥99 |

SiO2 | ≤13 | ≤8 | ≤0.2 | |

Fe2O3 | ≤0.5 | ≤0.5 | ≤0.5 | |

Apparent Porosity% | 58-62 | 58-62 | 58-62 | |

Bulk Density g/cm3 | 1.4-1.7 | 1.4-1.7 | 1.4-1.7 | |

Cold Crushing Strength Mpa | ≥12 | ≥10 | ≥9 | |

0.1Mpa Refractoriness Under Load T0.6 °C | ≥1650 | ≥1700 | ≥1700 | |

Permanent Linear Change On Reheating (%)1500°CX2h | ±0.3 | ±0.3 | ±0.3 | |

20-1300°C Thermal Expansion % (x 10-6) | 0-7.8 | 0-8.0 | 0-8.6 | |

Thermal Conductivity(Average 800°C) W/(M.K) | ≤0.8 | ≤1.3 | ≤1.5 | |

Max Service Temperature °C | 1680 | 1700 | 1800 | |

Packaging & Shipping

Quick Details

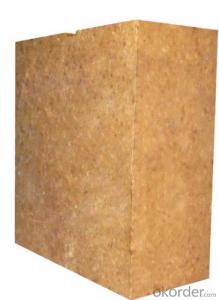

| Place of Origin: | Henan, China (Mainland) | Shape: | Block | Material: | Alumina Block |

| SiO2 Content (%): | 8 | Al2O3 Content (%): | 90 | MgO Content (%): | 0 |

| CaO Content (%): | 0 | Refractoriness (Degree): | Common (1580°< Refractoriness< 1770°) | CrO Content (%): | 0 |

| SiC Content (%): | 0 | Model Number: | AKZ-85 90 99 | Brand Name: | cnbm |

| Name: | high alumina bubble refractory bricks | size: | any size | Item: | AKZ-90 |

| Al2O3: | 90 | SiO2: | 8 | Fe2O3: | 0.5 |

| Apparent Porosity%: | 58-62 | Bulk Density g/cm3: | 1.4-1.7 | Cold Crushing Strength Mpa: | 10 |

| 0.1Mpa Refractoriness Under Load T0.6 °C: | 1700 |

Packaging & Delivery

| Packaging Details: | Wooden pallet or as the customer's requirments |

| Delivery Detail: | 30 Days |

- Q: Introduction of high alumina brick

- Made from alumina or other raw materials of high alumina content; formed and calcined. High thermal stability, fire resistance above 1770. Slag resistance is good, used for masonry steel smelting furnace, glass furnace, cement rotary furnace lining.

- Q: What are the grades of high alumina bricks?

- According to the size of high aluminum brick is divided into: standard brick, special-shaped brick.

- Q: What is the standard size of high alumina brick?

- The country has laid down a number of criteria for the use of refractory bricks to unify market demand.

- Q: What are the reasons for the decline in the performance of high alumina bricks when we use high alumina refractory bricks?

- All the raw materials adding order, mixing time, material and material moisture trapped. 4, the pressure and the volume density of Pei brick and brick Pei size etc..

- Q: How many cubic bricks does a high alumina brick have?

- It is related to the content of aluminum in high alumina bricks.

- Q: What are the common thermal insulation materials for thermal conductivity?

- Aerogels are known to be the lightest solid materials in the world. It is made of nanometer silica aerogel as main material and is compounded by special process. The utility model has the advantages of high temperature resistance, low thermal conductivity, small density, high strength, green environment protection, waterproof and non inflammable performance. At the same time, with excellent sound insulation and shock absorption performance, it is now widely used in metallurgy, chemical, national defense, aerospace and other fields, is an indispensable high-performance insulation materials.

- Q: The cloth blowing is not uniform on the lime kiln refractory brick is damaged it

- People with the shaft kiln cement clinker kiln, because of small size, low calcination temperature, using only Al2O3 containing a single clay brick is 30 ~ 40%, the rotary kiln was improved in the early Yuan faith this experience, use of high alumina brick and clay brick, from 60s onwards, due to large scale kiln and to strengthen the operation of the high temperature parts of kiln lining, alkaline brick masonry is widely used, the main varieties are: magnesia chrome brick, magnesia spinel brick and dolomite brick.

- Q: How to test the aluminium bricks of high alumina refractory bricks?

- Before making bricks, the raw materials are usually tested and tested to see if the aluminum content is up to standard

- Q: How to reduce the harm caused by two times mullite in high alumina refractory material

- Prolong the sintering time and adjust the aluminum content of the high alumina brick.

- Q: Is glass wool inorganic thermal insulation material?

- The use of glass wool, glass wool is usually used as raw materials of various types of insulation materials, such as glass wool board, glass wool, glass wool, glass wool pipe, can be used in the following areas:1) roof insulation, cold protection, sound-absorbing materials; 2) building exterior wall insulation and cold protection; 3) entertainment places, theaters, television stations, radio stations, laboratories, sound absorption treatment.

Send your message to us

High Alumina Brick - Professional Manufacturer for High Alumina Bubble Refractory Bricks

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 8000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords