High Alumina Brick for Hot-Blast Stove

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details for High Alumina Brick for Hot-Blast Stove

| Place of Origin: | China (Mainland) | Shape: | Brick | Material: | Alumina Block |

| SiO2 Content (%): | 22 | Al2O3 Content (%): | 65-75 | Model Number: | JDL-65/JDL-75 |

| Brand Name: | Refractoriness: | 1790 °C | Cetification: | ISO9001 |

Packaging & Delivery

| Packaging Details: | Fumigation wooden pallets+paper angle bead+PET strap+stretch film. |

| Delivery Detail: | More than 30 days after signing the contract |

Specifications for High Alumina Brick for Hot-Blast Stove

Characteristic:

1.High-temperature resistance

2.Lower creep rate

3.High strength

4.Good thermal shock resistance

![]()

This product is made by superfine calcined bauxite, additive and high-quality combined clay. This product has good performances of hot flue scouring resistance and corrosion resistance. Its apparent porosity is lower,strength is high and its creep rate is lower, so it means that this product can well keep stability under the load and high temperature.

![]()

| Item | JDL-65 | JDL-75 |

| Al2O3 % | 65 | 75 |

| Apparent porosity % | 22 | 20 |

| Bulk density g/cm3 | 2.4 | 2.6 |

| Cold crushing strength Mpa | 55 | 60 |

| Reheating linear change % | 1450°C×2h +0.1~-0.2 | 1550°C×2h +0.1~-0.2 |

| Creep rate 0.2MPa×50h % | 1400°C ≤0.8 | 1550°C ≤0.8 |

| Application | combustor, grid room, wind mix chamber | combustor, grid room, wind mix chamber |

![]()

It is widely used in regenerative chamber, combustion chamber,communication pipe and other parts of hot blast stove.

![]()

1.Strong professional:

A:The manager of our company has twenty years working experience in refractory product, technology and trading. He has professional function on a various refractory’ s production materials, process control, quality supervision and package delivery.

B: .Company staff are very familiar with refractory and professional knowledge is very good .

C:Company staff are all college culture level.

2. .Annual supply:

Our company has a dozen cooperative production factories which are better in productive technology and quality management. All the factories has passed ISO9001 quality management system certification. And the annual supply of dense shaped and unshaped refractory product is 100,000-200,000 tons.

3. Annual exports:

Now we have exported more than ten countries , such as Asia ,Europe and South America.The average annual export amount is 10 million Yuan , about $1.6 million.

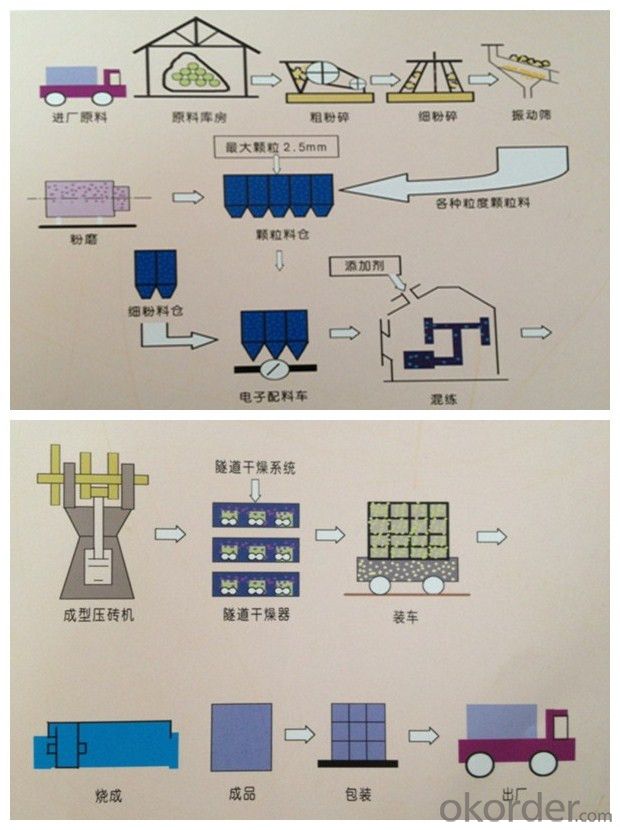

4. Production equipment:

Production and testing equipments are new, complete and automated or semi- automated. Such modern facilities and equipments have provided the fine technical guarantee for the production and testing.

5. Process flowdiagram:

6. Order processing:

After the contract is signed, the relevant responsible person tracked production progress, product quality and product packing aperiodically. During the term of contract sent on time with quantity and quality guaranteed.

- Q: Introduction of high alumina brick

- High alumina brick is one of refractory materials. The main component of this kind of refractory brick is AL2O3. If the content of Al2O3 is higher than 90%, it is called corundum brick. Because of the different resources, the standards of different countries are not identical. For example, European countries limit the content of Al2O3 to high alumina refractories by 42%. In China, the content of Al2O3 in high alumina brick is usually divided into three parts: I, etc. - Al2O3 content, >75%, II, etc. - Al2O3 content is 60 ~ 75%, and the content of Al2O3 is 48 ~ 60%.

- Q: What are the grades of high alumina bricks?

- According to the size of high aluminum brick is divided into: standard brick, special-shaped brick.

- Q: What is the difference between T3 refractory bricks and high alumina refractory bricks?

- The T3 in T3 refractory bricks refers to the model indicating that the refractory brick model is T-3, and that the corresponding T-3 model is 230*114*65 (mm)

- Q: Can high alumina brick resist carburizing?

- The key is to look at the content of Fe3O2 metal oxides (so-called anti carburizing brick generally refers to the content of Fe3O2 less than 1% clay brick and Gao Lvzhuan) just a photo shoot, out for everyone to see, high alumina brick common in reductive atmosphere has been chalking up.

- Q: Which is better, the soft core or the hard core?

- The wire has two kinds of hard core and soft core, the hard core line is only one wire core, and the soft core line has a plurality of wire cores. For the same sectional area, the 7 core is more than the more than 30 core. There is a difference in use. Generally used for DC is the use of hard core line, because of its small line consumption; and for communication, we should use soft core line, but also in order to reduce its line consumption

- Q: What kinds of minerals are there in the five major categories of ore crystal chemistry?

- Natural element minerals. Of minerals produced by an element (elementary substance). There are about 90 natural elements in the earth's crust, accounting for 0.1% of the total weight of the earth's crust. Can be divided into metal elements, mainly platinum and copper, silver, gold, etc., non-metallic elements, carbon, sulfur, etc., half metallic elements, arsenic, bismuth and so on.

- Q: How to test the aluminium bricks of high alumina refractory bricks?

- Before making bricks, the raw materials are usually tested and tested to see if the aluminum content is up to standard

- Q: Which thermal shock stability of clay brick and high alumina brick is good?

- Generally, the thermal shock resistance of high alumina brick products is worse than that of clay brick products

- Q: What are the categories of bricks?

- Ordinary brick size of 240 mm * 115 mm * 53 mm, according to compressive strength (Newton / square millimeter, N / mm2) size is divided into MU30, MU25, MU20, MU15, MU10, MU7.5, these intensity levels.

- Q: What should be used as binder for making high alumina bricks?

- Bond for making high alumina brick: soft clay has good plasticity, so the high alumina brick is usually made of soft clay as bond. However, the free Al2O3 free SiO2 and bauxite clinker clay in under 1200 degrees occurred two times of Mullization reaction, generate large volume expansion, silicon porosity, strength reduction. Therefore, the amount of clay powder in the ingredient should be no more than 5%.

Send your message to us

High Alumina Brick for Hot-Blast Stove

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords