High Alumina Brick Anchor Brick UAL60

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 200000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

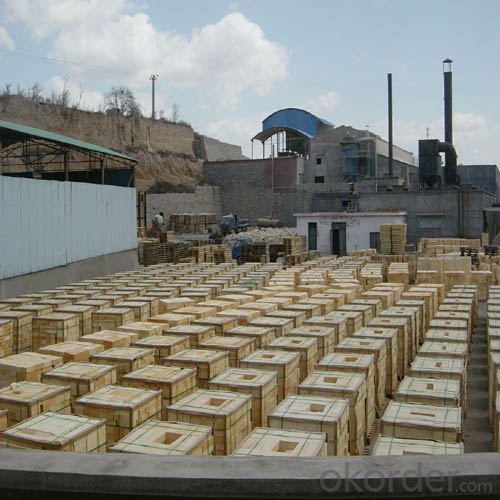

General Information of Anchor Brick

Our corporation’s refractory bricks include many kinds of anchor bricks,like UAL85, UAL75 and so on.

Our refractory bricks are in good quality and we can offer you the bestprice. Featuring huge volume density, high compressive strength, good thermalstability and strong impact resistance, all of our high-aluminum anchoragebricks, mullite anchorage bricks and burner bricks can be made into anyspecification defined by users to fit for different demands.

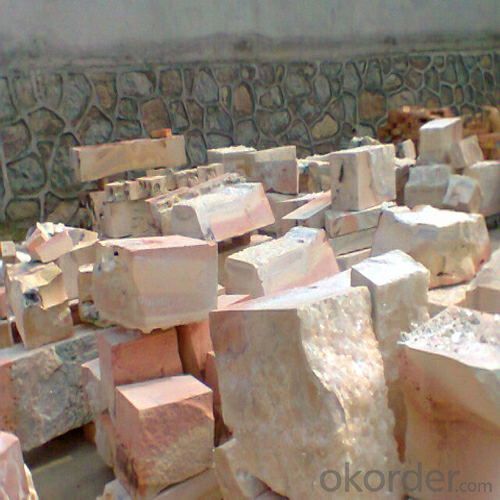

Features of Anchor Brick

Low thermal conductivity

Excellent acid and base slag resistance

High refractoriness

Excellent thermal shock resistance

Excellent mechanical strength

Applications of Anchor Brick

Our Anchor Brick UAL60 are commonly used in blast furnace, hotblast furnace, the roof of electric furnace, teeming ladle, rotary kiln,regenerator, etc. Our refractory brick have the capacity of maintainingexcellent mechanical behavior under high temperature,

Technical Data of Anchor Brick UAL60 | ||

Physical Properties: |

|

|

Refractoriness | ℃ | 1790 |

Permanent Linear Change(1500℃×2h)% | % | 0.1~﹣0.4 |

Apparent Porosity, % | % | ≤20 |

Cold Crushing Strength | Mpa | ≥55 |

Refractoriness Under Load (T0.6) | ℃ | ≥1450 |

Thermal Expansion, % | % | - |

Density | g/cm3 | 2.35 |

Chemical Analysis: |

|

|

Al2O3 | % | ≥60 |

Fe2O3 | % | 1.5 |

Note: | ||

- Q: What are the reasons for the decline in the performance of high alumina bricks when we use high alumina refractory bricks?

- Quality requirements for aluminium bricks of different grade. 2, high aluminum powder and high alumina aggregate and other materials of reasonable proportion, to reach the production requirements.

- Q: How are the high alumina bricks fired?

- Light and high alumina bricks are usually fired in a weak oxidizing atmosphere. In light and high alumina bricks firing, they are often rich in impurities such as R2O, RO, Fe2O3 and so on. They react with Al2O3 and SiO2 at high temperature to produce liquid phase. In the Al2O3 - SiO2 - R2O system, the growth rate of liquid phase increases with the increase of temperature at high temperature. So, because the increase of sintering temperature brings a lot of liquid phase, the decrease of liquid viscosity will lead to the deformation of brick and the decline of brick high temperature function. Therefore, the lower sintering temperature and longer holding time should be adopted in the sintering process dominated by liquid phase sintering. The production practice shows that the same firing temperature can be used for the high grade aluminum bricks. When fired in an inverted flame kiln, it is usually 1430 degrees centigrade and insulated by 40H. The high alumina bricks such as Ill are 1390~1420 degrees centigrade. When the tunnel kiln is fired, they are 1550 and 1450~1500 degrees centigrade respectively. High alumina brick is usually made of weak oxidizing atmosphere.

- Q: What are the common thermal insulation materials for thermal conductivity?

- Aerogels are known to be the lightest solid materials in the world. It is made of nanometer silica aerogel as main material and is compounded by special process. The utility model has the advantages of high temperature resistance, low thermal conductivity, small density, high strength, green environment protection, waterproof and non inflammable performance. At the same time, with excellent sound insulation and shock absorption performance, it is now widely used in metallurgy, chemical, national defense, aerospace and other fields, is an indispensable high-performance insulation materials.

- Q: What is the difference between T3 refractory bricks and high alumina refractory bricks?

- High aluminum refractory brick brick is all in one type of material classification, the material is AL2O3 high bauxite content above 55%, refractory brick by material into clay bricks, high aluminum brick brick brick corundum brick

- Q: How much is one ton / ton of high alumina refractory brick?

- The price of high alumina refractory bricks is not equal, according to the quality index of GB2988-2012

- Q: What are the specifications for bricks?

- Thecompressive node as a new type of building energy-saving wall materials, which can be used for masonry walls, but also has good thermal properties, in line with the construction of the building module, reduce the loss in the process of construction, improve work efficiency; the hole rate reached more than 35%, can reduce the weight of the wall, save the foundation engineering cost. Compared with common sintered porous brick, it has the characteristics of heat preservation, heat insulation, light weight, high strength and high construction efficiency. The product is made of shale as raw material. It is produced by high vacuum extrusion molding machine and one yard firing process

- Q: Are there any differences between insulating bricks and refractory bricks?

- The insulation performance of thermal conductivity of insulating brick in general 0.2-0.4 (average temperature 350 - 25 DEG C) w/m.k, and the thermal conductivity of refractory brick in 1 (the average temperature of 350 - 25 DEG C) above w/m.k, which can obtain the insulation performance of insulating brick than refractory brick insulation performance is much better.

- Q: How high can aluminum bricks expand at 80O degrees of heat?

- When an object is heated, the particle moves faster and thus occupies additional space. This phenomenon is called dilation.

- Q: Use of high alumina refractory bricks?

- High alumina refractory brick in Al2O3 more, close to neutral refractory material, can resist acid slag and alkaline slag erosion, because it contains SiO2, so alkaline slag ability than acid resistance slag ability less.It is widely used in building blast furnace, hot blast furnace, furnace top, blast furnace, reverberatory furnace and rotary kiln lining. In addition, high alumina bricks are widely used as furnace regenerative checker, pouring system for plug nozzle, etc..

- Q: Which thermal shock stability of clay brick and high alumina brick is good?

- High alumina brick is made of superfine alumina, fused corundum and fused mullite as main refractory materials.

Send your message to us

High Alumina Brick Anchor Brick UAL60

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 200000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords