Hexagonal Wire Mesh Galvanized /PVC Coated Good Quality Best Seller Fence

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Hexagonal Wire Netting Description:

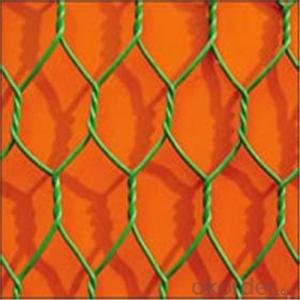

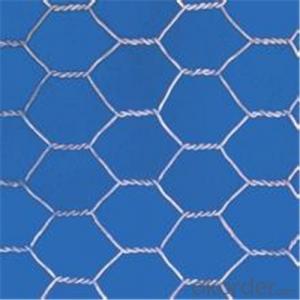

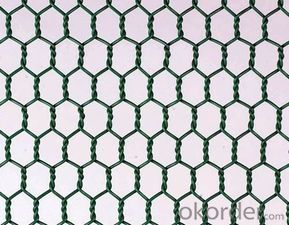

Hexagonal Wire Netting with its good corrosion resistance and oxidation resistance, serves well in strengthening protection and temperature keeping materials in the form of mesh container, stone cage, isolation wall, boiler cover or poultry fence in construction, chemical, breeding, garden and food processing industries.

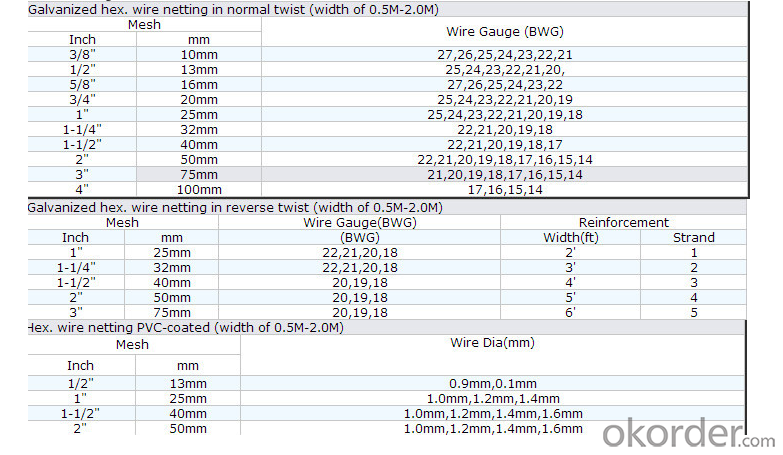

Hexagonal wire mesh is also called chicken wire, poultry netting ,rabbit netting. It is common used to fence chicken, poultry, rabbit and other animals.The hexagonal wire mesh is made of black iron wire, galvanized iron wire, brass wire or stainless steel wire with hexagonal gaps, available in3/8 inch to 4inch ( 10mm to 100mm),wire gauge from BWG14 to BWG27 (2.1mm to 0.4mm).

2.Main Features of Hexagonal Wire Netting:

• Nice Shape

• Use widely

• Solid

• Simple weaving

• Good anti-corrosion

• Practical use

3. Hexagonal Wire Netting Images

4. Hexagonal Wire Netting Specification

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Hexagonal Wire Netting?

We have 20 years' experience for export/produce Hexagonal Wire Netting. About 100 persons works in this line, 10 production lines can produce about 200 sets every day. We have our own quality inspection departments to strictly according to customer requirements to complete production. Which have exported to lots of countries before such as: Australia, Italy, Mexico, Gaborone, Kenya..... And so on. We have a professional management team and many skilled workers Owns 20 production lines, we have a strong production capacity We can provide high-quality products.

②What is the Hexagonal Wire Netting Accessories:

* Hex. wire mesh in normal twist

* Hex. wire mesh in reverse twist

* Hex. wire mesh in bidirectional twists

* Electro Galvanized before Weaving

* Electro Galvanized After Weaving

* Hot Dipped Galvanized before Weaving

* Hot Dipped Galvanized after Weaving

* PVC Coated Before or After Weaving

③How long can we receive the product after purchase?

In the purchase of Hexagonal Wire Netting within three working days, we will arrange the factory delivery as soon as possible. The pacific time of receiving is related to the state and position of customers. Commonly 15 to 20 working days can be served.

- Q: How the wire is welded

- Only electricity, and electrode grinding replacement costs. Welding costs are much lower than welding.

- Q: Barbed wire mesh 20 mesh and 30 mesh what is the difference

- The sparseness of the network is different, in general, the larger the mesh, the closer the mesh is. The smaller the mesh, the thinner the cell.

- Q: What is the mesh in the wire mesh specification?

- The number of wire mesh refers to the number of holes of 2.54 cm. The unit used to express the mesh in the mesh product specification is hole / cm or line / cm.

- Q: Construction in the wall and the beam at the junction of nail wire mesh what role

- Fixed pipe: the appearance of the insulation layer laying wire mesh with nylon tie to fix the pipe, characterized by fast construction, accurate positioning, the role of all the pipe device is good.

- Q: How does proe draw wire mesh?

- The main is the rest assured that the grid generation, first in accordance with the form of a grid to draw a curve, of course,

- Q: How does the "jagged" on the back of the knife cut the barbed wire?

- There are a lot of landmines, and there are limitations in the mine warfare, but there are limitations,

- Q: Why is the effect of electromagnetic radiation shielding with wire mesh?

- Living environment rarely have high-frequency equipment, so the high frequency magnetic field component is very small, 0.5 has been very small, unless the professional equipment is difficult to distinguish, so the change can not be measured.

- Q: Is the warm tube laid on top of the steel wire or below?

- it is unreasonable to warm the pressure is the provisions of the state, the general pressure after the pressure in an hour after the pressure change in the 0.02-0.05 between the normal, because the pipeline itself has a swelling and contraction process, As he did is to warm the pipe has been damaged

- Q: How is the wire mesh made

- First of all, the application of electrolytic pickling, high pressure flushing, card electric drying of the new technology successfully tested the continuous production of the wire drawing, the drawing process from the intermittent production into a continuous production, weakened the labor intensity and reduce the metal consumption.

- Q: Why do you want to shop a barbed wire?

- Barbed wire to determine a good fixed later, you can start plastering, of course, this step is also a measure of the degree of intentions of tileworkers, plaster live to do more detailed, the more flat the wall, the latter part of the possibility of the problem will be relatively small some.

Send your message to us

Hexagonal Wire Mesh Galvanized /PVC Coated Good Quality Best Seller Fence

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords