Hesco Barrier/ Hesco Bastion/ Welded Gabion Box

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 set

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

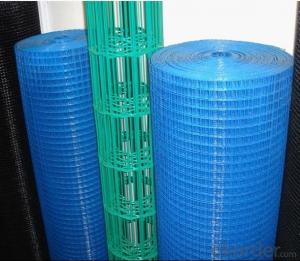

Hesco barrier also named as Hesco bastion, Hesco defense wall, sand cage, welded gabion box, etc. It is a prefabricated, multi-cellular system, made of zinc coated steel welded mesh and lined with non-woven geotextile. Units can be extended and joined using the provided joining pins. It is easy installed with using minimal manpower and commonly available equipment. After extended, it is filled into sand, stone, then hesco barrier like a defence wall or bunker, it is widely used for military fortification and flood control. Accessories Supplied With Carrier Units

Hesco Military Specification: See the table below.

Typical Applications Include

? Perimeter Security and Defence Walls

? Equipment Revetments

? Ammunition Compounds

? Personnel and Material Bunkers

? Observation Points

? Defensive Firing Positions

? Entry Control Points

? Guard Posts

? Explosives and Contraband Search Areas

? Highway Checkpoints

? Border Crossing Checkpoints

? Protecting Existing Structures

? Highway Traffic Management

? Hostile Vehicle MItigation

Q&A

Q: What's main product?

A: Metal fencing and security wire.

Q: What's the gurantee of product?

A: products are certified by ISO9001: 2008, and guaranteed at least 5 to 10 years.

Q: What's after service policy?

A: after service staff will contact you when you received the products, and ask for your comments on the products.

Any issues on products, please send email to or call us,we will service you timely with whole-heartedness and profession.

Q: What's the MOQ of product?

A: Different item has different MOQ. Normally 1X20FCL is preferred, LCL could be negotiable.

Q: How can we get the quotation?

A: Please send your inquiry to official.

Q: How to be agent, wholeseller or distributor in my country?

A: Please send your company's basic information and application . A feedback will be sent to you within 7 working days.

| Mesh wire diameter | 3mm,4mm,5mm,6mm etc |

| Mesh Size | 2''x2'', 3''x3'', 4''x4'', etc |

| Spring wire diameter | 3mm,4mm,5mm,6mm etc |

| Panel Finish | Hot dipped galvanized Galfan coated |

| Geotextile | Heavy duty non-woven polypropylene, color can be white, beige-sand, olive green, etc |

| Packing | Wrapped with shrink film or packed in pallet |

- Q: What is the process of the screen printing process?

- Screen printing features ① wide adaptability: screen printing format can be small or small; ② thick ink: in all printing process, the screen printing ink the thickest, high saturation, spot color printing better; ③ low cost

- Q: What are the reasons for the hair making of the screen plate?

- Exposure time is the most important, lack of time, after the version of the mucus to stay in the screen, affecting the printing edge, a long time, it is not easy to open the screen, it will be printed edge defects caused by burr.

- Q: Screen printing and other printing methods of the difference

- Printed high weatherability, fastness. Simple operation procedure, simple tool / machine, relatively low investment, high return rate.

- Q: What is the commonly used mapping software for screen printing?

- the vector is based on geometric characteristics to draw graphics, the vector can be a point or a line, the vector can only rely on software generated, the file occupies less internal space, because this type of image file contains separate separate images, Free unlimited reorganization.

- Q: Screen printing and screen printing plate on the photosensitive material What are the requirements

- Synthetic fiber or metal frame pattern using hand-painted film or photochemical plate making silk screen version of the modern silk printing technology is the use of optical materials through the system plate production

- Q: How to clean the screen plate

- Reset, in order to achieve the next work process to facilitate the operation of personnel cleaning wire mesh, a substantial increase in production efficiency, which due to cleaning the liquid can be used in the machine to achieve recycling,

- Q: Screen printing ink firmness problem

- If it is PVC tablecloth, you can try to corona the first surface of the printing process, so that the surface tension higher (recommended to 55 - 60 dyne), and then see if there is improvement.

- Q: Screen printing, how to choose the screen

- Stainless steel screen printing network tension good strength high printing effect good for printing precision products such as solar panels circuit board printing

- Q: How to make screen printing layout smooth

- Photosensitive glue in the printing surface glue 2-3 times, the back of the plastic once. Complete the photosensitive / developed after drying and curing,

- Q: Screen printing and printing the difference

- ink, pressure and other processes, so that ink transferred to paper, fabric, Leather and other materials on the surface, the bulk copy of the original content of the technology.

Send your message to us

Hesco Barrier/ Hesco Bastion/ Welded Gabion Box

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 set

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords