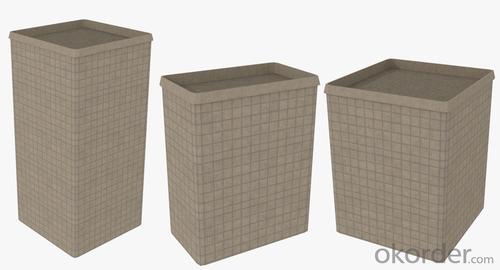

Gabion Box in Military/ Hesco Bastion/ Welded Gabion Box

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 set

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Hesco barrier is gabion-like. It is a combination of welded wire mesh frame outside and non-woven geotextile liner inside. Sand, soil, gravel and blinding are frequently used as filling because of geotextile liner.

Gabion bastions are mainly used in military and flood control for its modular structure and quick setup. For military, a gabion Hesco with 24 inches thickness can stop rifle bullets, shell fragments and other shrapnel. While for flood protection, gabion Hesco can be assembled soonest and come into use.

HESCO products have been used in many countries around the world including Afghanistan, Iraq, Bosnia, Kosovo, Yemen, Sri Lanka, Jordan, UAE and Turkey. Most military organizations currently use HESCO products including the US Army, UK MOD, USMC, USAF and NATO.

In addition to the standard Container unit, HESCO is constantly developing its portfolio of products in response to its customers' requirements. Multi-cellular wall system force protection product

HESCO container applications:

HESCO Basion In Military

HESCO Barrier In Humanitarian

HESCO Blast Wall In Humanland Security

Military Bastion Barrier In Civil Engineering

HESCO Technical Information

1. HESCO Blast Wall

HESCO Blast Wall (also named HESCO bastion, HESCO barrier) has been on hand to aid civil engineers with a wide range of environmental issues for over 10 years. Originally designed to combat the effects of coastal erosion, HESCO Bastion Container has since been used extensively throughout the world for other civil engineering applications.

The versatility of a HESCO Barrier Container structure enables it to be used across a variety of applications such as coastal erosion, flood protection, river and bank stabilisation, retaining walls, land reinforcement and soil conservation.

A galvanized steel unit lined with geotextile fabric, HESCO Barrier Concertainer is completely assembled during manufacture, ensuring rapid installation. Available in a wide range of sizes, units can be joined and extended using the provided joining pins. The primary advantage of the product is its ability to utilise locally available fill material to rapidly construct walls and other structures with minimal manpower and resources.

2. HESCO Container

The Container unit is a multi-cellular wall system manufactured from welded Zinc-Alu coated steel wire mesh and joined with vertical, helical coil joints. The units are lined with heavy-duty non-woven polypropylene geotextile.

The Container unit's primary advantage over other force protection systems is its ability to utilize locally available fill material to rapidly construct defensive barriers and other structures with minimal manpower and resources.

Units can be extended and joined together to provide effective and economical structures tailored to the specific threat and level of protection required. Container units are available in a variety of different sizes and delivery systems.

Hesco barrier structure

Similar to beehive, Hesco barrier is comprised of external welded gabion and interior fabric liner. Its content includes soil, sand or little stone. The line would be yellow, grass green or other colors which blends well with the surroundings.

Joining pins are supplied to join units together. Plastic ties are supplied to close the geotextile together at the top of unit ends, which prevents fill material from falling between unit joints.

General specifications:

Geotextile lined welded wire fabric gabion to ASTM A 974-97.

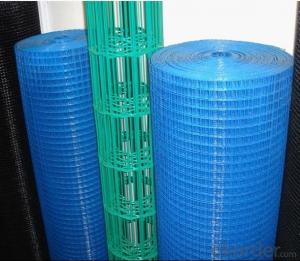

Welded Mesh, coils and pins

The Concertainer units are manufactured with a Alu-Zinc coated welded wire mesh. The mesh has a spacing of 3" x 3" and a wire gauge of 8.5 American SWG, steel/diameter of 0.155"/3.937mm (nominal).

Geotextile:

The geotextile is a heavy-duty, non-woven, permeable, polypropylene fabric, available in either green or sand color.

Please feel free to contact us if you do not see what you need, we will help you.

| Item | Wire Dia. | Mesh | Height | Width | Length | Cells |

| (mm) | (mm) | (Meter) | (Meter) | (Meter) | (pcs/unit) | |

| HB61T | 4.0 | 76.2*76.2 | 0.61 | 0.61 | 1.22 | 2 |

| HB61F | 4.0 | 76.2*76.2 | 0.61 | 0.61 | 3.05 | 5 |

| HB61S | 4.0 | 76.2*76.2 | 0.61 | 0.61 | 6.1 | 10 |

| HB100S | 4.0 | 76.2*76.2 | 1.00 | 1.50 | 10 | 6 |

| HB100N | 4.0 | 76.2*76.2 | 1.00 | 0.76 | 9.14 | 9 |

| HB100T | 4.0 | 76.2*76.2 | 1.00 | 1.00 | 10 | 10 |

| HB137N | 4.0 | 76.2*76.2 | 1.37 | 1.06 | 10 | 9 |

| HB137T | 4.0 | 76.2*76.2 | 1.37 | 1.22 | 10 | 9 |

| HB168F | 4.0 | 76.2*76.2 | 1.68 | 0.61 | 3.05 | 5 |

| HB213F | 4.0 | 76.2*76.2 | 2.13 | 1.52 | 7.62 | 5 |

| HB221F | 5.0 | 76.2*76.2 | 2.21 | 2.13 | 8.52 | 4 |

- Q: On the issue of their own screen printing

- Printed clothes must first have a printed version of the screen, clothing version with 120 or 130 mesh screen to do, with the version, scraper, ink, you can start printing color clothes need color, only one color

- Q: What is the process of the screen printing process?

- Carton printing, that is, directly in the already made a good corrugated boxes or other cartons, cartons for screen printing; ③ secondary processing, that is, first in the cardboard on the screen printing, and then according to the need to produce corrugated cardboard

- Q: What are the reasons for the hair making of the screen plate?

- The tension of the screen is a little bit (generally if the fingerprints, the recommended tension of 19 or so.

- Q: Screen printing, how to print circular arc surface

- In the net below the pad a sponge than the thickness of the screen slightly higher, the size of the sponge larger than the text part of the ink will be adjusted after the screen set off, evenly coated on the sponge.

- Q: Screen printing and other printing methods of the difference

- Ink variety, can print a variety of special effects, three-dimensional sense of strong. The printing method is infinitely changing.

- Q: Screen printing and screen printing plate on the photosensitive material What are the requirements

- Synthetic fiber or metal frame pattern using hand-painted film or photochemical plate making silk screen version of the modern silk printing technology is the use of optical materials through the system plate production

- Q: Screen printing, how to choose the screen

- Stainless steel screen printing network tension good strength high printing effect good for printing precision products such as solar panels circuit board printing

- Q: How to make screen printing layout smooth

- Photosensitive glue in the printing surface glue 2-3 times, the back of the plastic once. Complete the photosensitive / developed after drying and curing,

- Q: Screen printing and printing the difference

- Printing (Graphic Arts, also use Graphic Communications that is graphic transmission) is the text, pictures, photos, security and other originals by plate making,

- Q: What are the characteristics of screen printing?

- Ink layer thick coverage, for all types of ink, light resistance, flexible printing and diverse

Send your message to us

Gabion Box in Military/ Hesco Bastion/ Welded Gabion Box

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 set

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords