Ceramic Fiber Board - Heat Resistance Insulation Alumina Silicate

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of ceramic fiber boards

CMAX ceramic fiber boards are manufactured in a wet vacuum forming process by blending the chopped ceramic fiber with inorganic or organic binders for excellent abrasive resistance at high temperature.

CMAX ceramic fiber boards feature low thermal conductivity, high thermal stability and excellent thermal shock resistance.

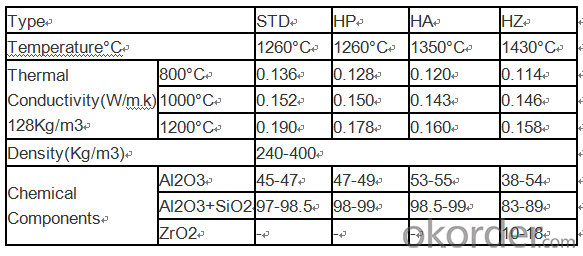

The products are classified as STD, HP, HA and Hz respectively corresponding to different maximum service temperature 1000º C, 1100º C, 1200º C and 1350º C.

Application of Mission Alumina ceramic Fiber Board:

Furnace lining and backing of various high temperature furnace and kiln.

Product Advantages:

1. Good High temperature stability, Low thermal conductivity,

2. Good thermal shock resistance, Corrosion resistance

3. Easy to be machined and cut.

4. Good resistance of fire and high temperature gases.

5. Easy to installed.

Ceramic Fiber Board main feature:

1. High quality kiln alumina ceramic fiber board

2. High working temperature.

3. Fast delivery and very competitive prices.

Ceramic fiber board for sale in the world is our main product. Mission can supply Industrial ceramic fiber in the world .Mission can make high quality alumina fiber blanks and blanket. They are widely used as furnace lining in all kinds high temperature furnace and kiln. And also used for other high temperature resistance application.

Product Specifications:

FAQ:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: What method should be used to measure the thermal conductivity of fiberboard?

- It is concluded that the test error of this method and device is about 2%. This filament ultra light aluminum silicate fiber product: the filament ultra light aluminum silicate product is by Shandong Zibo high quality burnt precious stone as raw material, passes through the smelting furnace, the rejection silk, blows the cotton, the auxiliary mold and so on to deliver the work procedure. Therefore, the thermal conductivity of fiberboard is chosen by heat flow meter method.

- Q: What are the standards for ceramic fiber boards?

- The existing ceramic fiber board has broken through the age of fear of water, and the newly developed hydrophobic ceramic fiber board has the characteristics of normal working under the water environment.

- Q: Refractory insulation board, pressure plate, nano heat transfer plate, calcium silicate board and ceramic fiber board, which is good?

- Ceramic fiber boardCeramic fiber board product categories:1260 standard ceramic fiber board sygx-264 1260 high purity ceramic fiber board sygx-3641400 zirconium ceramic fiber board sygx-564 1400 high alumina ceramic fiber fire plate sygx-464D1400 zirconium ceramic fiber fire baffle sygx-564D

- Q: What are the sound-absorbing fiber boards?

- Sound-absorbing material:1, itself has sound-absorbing properties, porous fiber material.2, does not have sound-absorbing material, but processed into sound absorption structure.Common sound-absorbing materials are: polyester fiber sound-absorbing board, trough wood sound absorption board, hole wood sound-absorbing board, recycled wood sound-absorbing board, the latest is Dr. sound, high temperature ceramic sound-absorbing board, a fire prevention, water quality, hard environmental protection

- Q: What is the difference between ceramic fiber board and nano ceramic fiber board?

- The traditional ceramic fiber board has good heat insulation, high temperature resistance to certain characteristics, widely used in kiln products, but this tradition also has some shortages, low intensity, high temperature and high pressure, there are restrictions on the application of kiln stress.

- Q: What are the specifications of the ceramic fiber board?

- Ceramic fiber board common specifications are: 600*400, 900*600, 1000*600 and 1000*1200mm, thickness 10/20/25/30/40/50mm, thinnest can do 6mm.Depending on the temperature range, it can be divided into:Common ceramic fiber board HLGX-164Standard ceramic fiber board HLGX-264High purity ceramic fiber board HLGX-364High alumina ceramic fiber board HLGX-464Ceramic fiber board containing zirconium HLGX-564

- Q: What are the differences between nano ceramic plate and ceramic fiber board?

- The biggest difference between the two is that:1, the coefficient of thermal conductivity is different, the nano ceramic plate is about three times of the ordinary ceramic fiber board2, temperature class is not the same, nano ceramic board maximum temperature of 1050 degrees, ceramic fiber board should be 1400 degrees temperature.3, the range of applications is different. Nano ceramic plate is mainly used in high, fine and sharp technical fields, and has strict requirements on thermal conductivity. Ceramic fiber boards are widely used and can be used wherever there is flame or temperature.

- Q: What are the uses of ceramic fiber boards?

- According to the conditions of use, can be divided into:Fire dragon high purity ceramic fiber fire block HLGX-364DThe dragon high alumina ceramic fiber fireproof plate HLGX-464D

- Q: Is there any difference between ceramic silicon fiber board and ceramic fiber board?

- 1, high compressive strength, long service life; 2, low heat capacity, low thermal conductivity;3, non brittle material, good toughness;4, accurate size, good flatness;5 、 easy to cut and install, easy to construct;6, excellent wind erosion resistance;7 、 continuous production, uniform distribution of fiber, stable performance.

- Q: How much pressure can the ceramic fiber board withstand?

- Ceramic fiber board has the characteristics of tough, high compressive strength, excellent resistance to high temperature and excellent supporting force. The compressive strength of ceramic fiber board increases with the increase of density of ceramic fiber board.

Send your message to us

Ceramic Fiber Board - Heat Resistance Insulation Alumina Silicate

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords