Heat and Fire Resistant Borosilicate Float Glass for Glass facades

- Loading Port:

- XINGANG

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

1.Description:

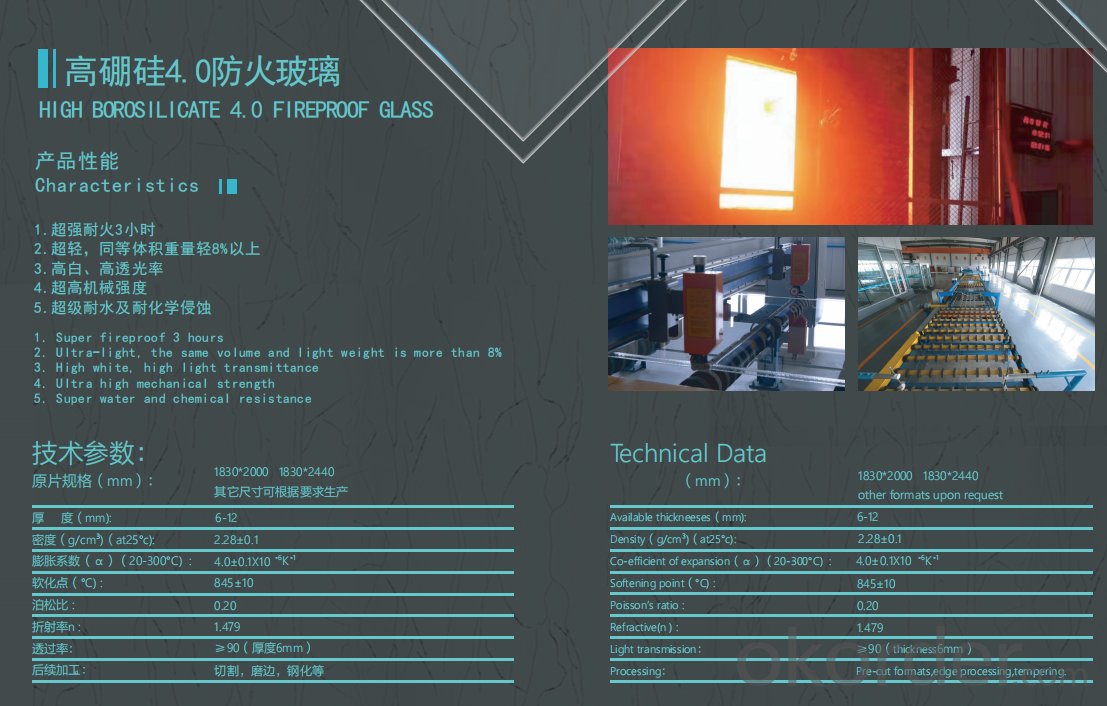

Borosilicate fire-resistant glass is a kind of outstanding material and this glass has a wide range of safety applications. That can be used as single or insulating glass and meet different protection requirements.

2. Main features

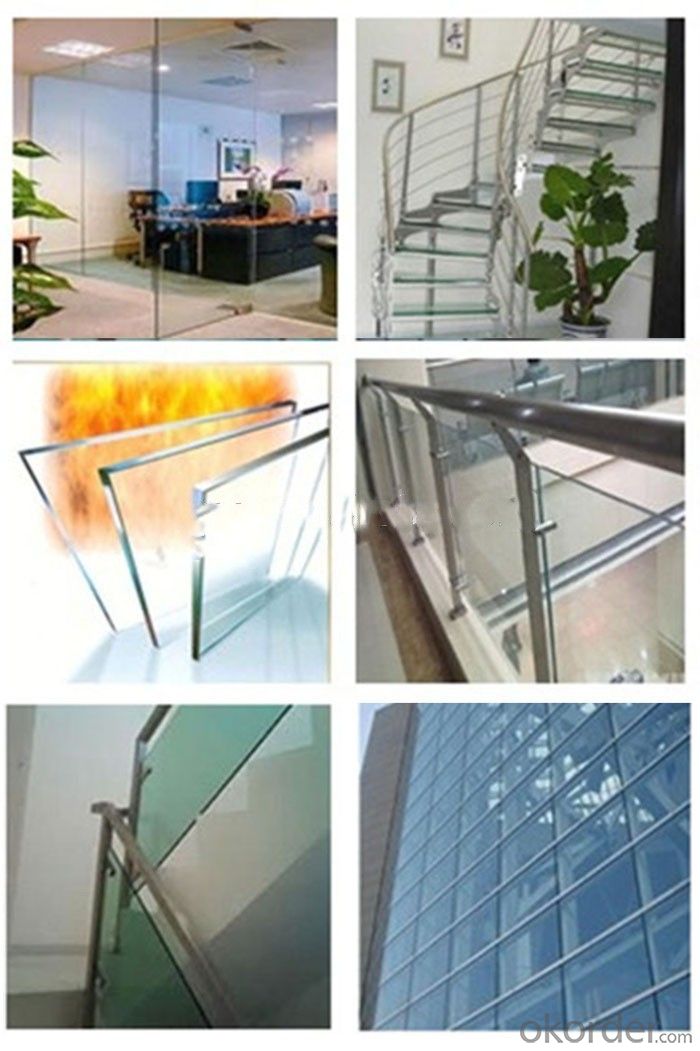

3. Application:

4. packing and shipping:

- Q: What is the raw material for making glass?

- The main raw material is quartz sand. Because of the high melting point of quartz sand, it is necessary to add a flux of sodium carbonate (that is, our usual surface base) to molten glass when melting,

- Q: What's the name of the transparent plastic board in the market?

- Organic glass acrylic and special processing, organic glass products, light boxes with acrylic production has good transparence, pure color, rich colors, beautiful smooth, both day and night of two kinds of effect, long service life, does not affect the use of other features, in addition, acrylic and aluminum plate material, advanced screen printing etc. can be the perfect combination, to meet the business needs of acrylic plastic is to improve the store level business, unified enterprise image of the best form of outdoor advertising.

- Q: How is glass made?

- Ordinary glass plate glass, wire glass and quartz glass (also known as crystal glass) a molding. Wired glass as the quartz glass; only a raw material of sandstone or silica or quartz sand.Tempered glass is made of flat glass as raw material for re processing: the cut of the flat glass into the tempering furnace, heating to about 650 degrees, with cold air quenching, glass forming hardening - tempering. Accomplish!

- Q: Acrylic plexiglass rod can be used in what way?

- The disadvantages are complicated operation, great difficulty, slow curing time, and difficult to meet the requirement of mass production. The general characteristics and one component adhesive is fast and can meet the requirements of mass production process, product defect is after bonding of the bubbles, easy white, poor weather resistance, beautiful appearance and poor quality. In addition, the adhesive bonding process skill is also very important, there are several common a, docking: acrylic plate the level of two block to be docking on the operating platform, closed, and at the bottom of a sticky tape, leaving a gap of not more than 0.3mm wide for coating adhesive injection.

- Q: Can the toughened glass be cracked by the sun?

- high strengthThe toughened glass of the same thickness has 3~5 times the impact strength of ordinary glass, and the bending strength is 3~5 times of that of ordinary glass.

- Q: What is the raw material of glass glue?

- Mainly divided into two categories: neutral acid silicone rubber polyurethane adhesive can be indoor and outdoor weathering 107 RTV silicone rubber and calcium carbonate, silica, additives, mixing, vacuum glass glue chemical formula: 107RTV+SiO2+CaCO3= glass glue according to the technical requirements of the chemical equipment selection will differ.

- Q: What are the raw materials for producing edible glass bottles (such as pickles bottles, fermented beancurd bottles, etc.), and glass is the kind of glass material?

- In the production of glass products, raw materials are divided into general white material, high white material, super white material, and white material, the quality is getting better, he directly affects the glass transparency and crispness, better raw materials produced better quality glass products.

- Q: Tempered glass and ordinary glass raw materials the same, but the manufacturing method is different, why first heating in rapid cooling, the difference is so great?

- When the glass is heated to a suitable temperature, it cools rapidly, causing a sharp contraction of the glass surface and a compressive stress, while the cooling in the middle of the glass is slower and it is too late to shrink, thus forming a tensile stress and making the glass obtain a higher strength. Generally speaking, the higher the cooling intensity, the greater the strength of the glass.

- Q: How do you pack something into (Qian Jin) plexiglass?

- I have been in touch with gel products for a while, and I feel that if the discharge circuit is too soft, it will be easy to damage the circuit board. As far as plexiglass is concerned, I have to ask my fellow inorganic students how they did it.

- Q: Is flat glass the main material or structural component in raw materials?

- But sometimes the structural parts, such as the exhibition hall and the hall, have a transparent floor beneath which the contents are displayed. In order to save the raw materials, they may be designed to be cut from the whole glass without cutting into the box. At this time the flat glass is load-bearing components, to calculate its carrying capacity, which is the structural components of the.

Send your message to us

Heat and Fire Resistant Borosilicate Float Glass for Glass facades

- Loading Port:

- XINGANG

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches