HD Model Electric Single Girder Overhead Crane, Overhead Crane, Single Girder

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Profile

HD type electric single-beam overhead crane is a kind of light-small general lifting equipment. Lifting capacity of it can ranges from 1t to 20t. Span: 7.5~31.5 meter. The HD type electric single-beam overhead crane travels on two pathways, which can be operated in six different directions, such as up and down, right and left, front and rear. The HD type electric single-beam overhead crane is widely used in machine manufacturing, petroleum, petrochemical, harbour, railway, civil aviation, electric power, food, paper making, building materials, electronic engineering and other industry to handle the materials in workshop and warehouse. Benchmark job working classification is A5(FEM:2m). Power source adopts three phase AC. Rated voltage adopts 380V~415V. Frequency is 50Hz. Also, it can choose 460V~480V rated voltage, 60Hz power source. Voltage fluctuation can be ±10%.

Crane consists of electric hoist, crane span structure, traveling mechanism of crane, electrical control system and other main parts. The lifting of crane adopts double speed (Speed ratio is 6:1). Also, it can adopts frequency control. The traveling mechanism of trolley and crane adopt frequency speed control(Speed ratio is 10:1). This product is widely used in machine manufacturing, metallurgy, petroleum, petrochemical, harbour, railway, aviation, electricity, food, paper making, building materials, electronic industry to handle the material in warehouse and plant. Especially, it applies to those place where it needs precise pinpoint to handle the material and large components and parts to assemble precisely. The main operation methods contain ground hand shank control and remote control.

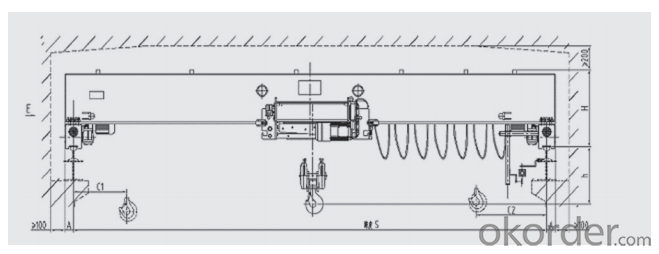

Sketch

In line with FEM Standard, HD type electric single-beam overhead crane is designed and manufactured with the following advantages, such as tight structure, small impact, convenient operation, low noise, safety and reliability, good appearance and etc. It belongs to ultra-headroom type crane. Equipped together with lifting mechanism of headroom electric hoist, it has a small size between the top of crane and the hook, which can improve the service space of hook. Then, it can effectively save plant space and investing cost. Building block design embodies the high performance of the crane. Almost all of the lifting mechanisms adopt three-in-one structure. It adopts hard tooth face design, which can quite reduce maintenance times. Also, it has the advantages of overload protection, over current protection, no-voltage protection and other kinds of protection. The applied automatic detection security monitoring and control and anti-sway system make the HD type electric single-beam overhead crane come to perfect.

The crane span structure is three beam split structure( one girder and two end girders). The girder adopts high-strength bolt to connect, which can avoid weld deflection between girder and end girders. It has the characteristics of light and small structure, high anti-fatigue ability, high precision of assembling, convenient transportation and installation. The girder is welded box structure. The bottom flange plate is the traveling track of electric hoist. It is manufactured in according to strict technological process. Before the steel plate is welded, it has been pretreatment. The welding adopts automatic gas shielded welding with small welding deflection, high weld strength, small residual stress and etc. The end girder adopts rectangle tube overall end beam or box beam structure. It adopts boring machine large landing to clamp entirety and manufactures a boring, which can insure vertical divergence value of wheel in the range of franchise with a precision of installation. It also makes the crane operate stably and prolongs the service life of the crane. What’s more, it also can prolong the service life period of plant.

Entire allocation of electric hoist adopts parallel connection (C type structure). In other words, the gear reduction and motor of winding drum are set in the way of parallel. In this way, it can decrease the size of length and increase the horizontal service space with a tight structure. The motor and gear reduction are convenient to install and maintain. The transmission system adopts closed type structure design. When it is in operation, the transmission gears are soaked into lubricant, which can improve the service life of gears and reduce noise.

The crane traveling mechanism adopts three-in-one drive method that it contains electric motor, gear reduction and brake. The double drive drives two end girders. With a large torque and low speed, the drive can avoid violent shaking when the machine is gradually to speed up and slow down stably. The install method adopts hollow shaft with a large torque and convenient installation. The fore stand plate of end girder is detectable which aims to observe the wear pattern of traveling wheel surface. It adopts high strength and wear proof forged wheel. The bearing of loading wheel adopts self-aligning roller bearing. Not only can it support vertical load, but also it can support horizontal load.

Product parameter

Benchmark working classification is A5(FEM:2m), standard traveling speed of crane is 3~30m/min, traveling speed of electric hoist is 2~20m/min, lifting height of the crane is 6~15m. The lifting speed and C1 value will be changed as the change of lifting height.

Technical specification

Lifting capacity(t) | Span(m) | Lifting height(m) | Lifting speed(m/min) | Power of crane(kW) | Weight(kg) | MAX. Wheel load(kN) | Basic dimension (mm) | ||||||

H | h | C1 | C2 | A | W | B | |||||||

1t | 7.5 | 6 9 12 15 | 0.8/5 | 3.95 | 1700 | 8.7 | 618 | 330 | 760 980 1200 1420 | 940 | 100 | 2000 | 2674 |

10.5 | 1932 | 9.5 | 618 | ||||||||||

13.5 | 2280 | 10.4 | 698 | ||||||||||

16.5 | 2704 | 11.5 | 768 | 2500 | 3174 | ||||||||

19.5 | 4.19 | 3299 | 13.0 | 798 | 3000 | 4174 | |||||||

22.5 | 3921 | 14.6 | 858 | ||||||||||

25.5 | 4514 | 16.1 | 928 | 3500 | 4174 | ||||||||

2t | 7.5 | 6 9 12 15 | 0.8/5 | 4.31 | 1811 | 13.5 | 708 | 330 | 760 980 1200 1420 | 940 | 100 | 2000 | 2674 |

10.5 | 2081 | 14.4 | 708 | ||||||||||

13.5 | 2451 | 15.5 | 778 | ||||||||||

16.5 | 3188 | 17.4 | 818 | 2500 | 3174 | ||||||||

19.5 | 4.67 | 3773 | 18.9 | 888 | 3000 | 4174 | |||||||

22.5 | 4344 | 20.3 | 968 | ||||||||||

25.5 | 5141 | 22.3 | 989 | 3500 | 4174 | ||||||||

3.2t | 7.5 | 6 9 12 15 | 0.8/5 | 4.31 | 1861 | 18.9 | 758 | 330 | 760 980 1200 1420 | 940 | 100 | 2000 | 2674 |

10.5 | 2098 | 20.1 | 758 | ||||||||||

13.5 | 2687 | 21.8 | 808 | ||||||||||

16.5 | 3344 | 23.5 | 908 | 2500 | 3174 | ||||||||

19.5 | 4.67 | 4121 | 25.4 | 948 | 3000 | 4174 | |||||||

22.5 | 4745 | 27.0 | 1028 | ||||||||||

25.5 | 6164 | 30.6 | 1178 | 230 | 3500 | 4174 | |||||||

5t | 7.5 | 6 9 12 15 | 0.8/5 | 9.25 | 2218 | 28.2 | 788 | 410 | 800 1030 1260 1490 | 940 | 100 | 2000 | 2674 |

10.5 | 2571 | 29.7 | 788 | ||||||||||

13.5 | 3245 | 31.8 | 908 | ||||||||||

16.5 | 3978 | 33.8 | 978 | 2500 | 3174 | ||||||||

19.5 | 9.65 | 4633 | 35.6 | 1138 | 310 | 3000 | 4174 | ||||||

22.5 | 6280 | 39.7 | 1258 | ||||||||||

25.5 | 7201 | 42.6 | 1288 | 3500 | 4174 | ||||||||

10t | 7.5 | 6 9 12 15 | 0.8/5 | 12.1 | 2696 | 51.8 | 908 | 465 | 810 980 1150 1320 | 1020 | 100 | 2000 | 2674 |

10.5 | 3200 | 54.4 | 908 | ||||||||||

13.5 | 4091 | 57.7 | 1008 | ||||||||||

16.5 | 5307 | 60.8 | 1208 | 365 | 2500 | 3174 | |||||||

19.5 | 12.8 | 6466 | 64.0 | 1308 | 3000 | 4174 | |||||||

22.5 | 7694 | 67.2 | 1358 | ||||||||||

25.5 | 9309 | 71.3 | 1482 | 345 | 120 | 3500 | 4174 | ||||||

16t | 7.5 | 9 12 15 | 0.66/4 | 19.7 | 83.7 | 1138 | 840 | 1520 1720 1920 | 1470 | 120 | 2000 | 2674 | |

10.5 | 85.7 | ||||||||||||

13.5 | 20.5 | 88.9 | 1273 | 805 | 140 | ||||||||

16.5 | 91.4 | 1425 | 2500 | 3174 | |||||||||

19.5 | 95.2 | 1475 | |||||||||||

22.5 | 99.3 | 1575 | 3000 | 3674 | |||||||||

25.5 | 104.7 | 1701 | 780 | 3500 | 4234 | ||||||||

20t | 7.5 | 9 12 15 | 0.66/4 | 20.5 | 4427 | 104.0 | 1275 | 905 | 1660 1900 2140 | 1470 | 140 | 2000 | 2674 |

10.5 | 5113 | 105.7 | |||||||||||

13.5 | 6399 | 109.1 | 1375 | ||||||||||

16.5 | 8077 | 113.5 | 1501 | 880 | 2500 | 3234 | |||||||

19.5 | 9611 | 117.2 | 1601 | ||||||||||

22.5 | 11641 | 121.6 | 1701 | 3000 | 3734 | ||||||||

25.5 | 13318 | 125.5 | 1801 | 3500 | 4234 | ||||||||

Notes: The above parameter applies to 380V50HZ power source. The rate of power and speed is various in according to different parts.

FAQ

If the space above the track is not enough or the use want to make use of the space as soon as possible.

The H value is various, the connection measurement between girder and end girder can adopts different ways in line with different conditions, such as seat-type connection, high limit connection and heightening connection, which can make great use of space.

Whether if the speed can be adjusted?

In the technical chart, the speed refers to the normal speed that it applies to majority working condition. If something speciality is needed to design, it also can be realized in a limited range.

Send your message to us

HD Model Electric Single Girder Overhead Crane, Overhead Crane, Single Girder

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords