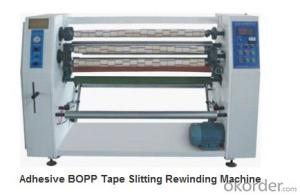

HCHS2002A Saeries BOPP Tape Slitter Rewinding Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 15 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of HCHS2002A Saeries BOPP Tape Slitter Rewinding Machine

1. The slitter rewinder machine is suitable for slitting BOPP packaging & stationery tapes.

2. 4 shafts automatic exchange..

Application of HCHS2002A Saeries BOPP Tape Slitter Rewinding Machine

the Bopp adhesive tape slitter rewinder machine is 4 shafts auto turret exchange, suitable for slitting rewinding BOPP packaging & stationery tapes.

Specification of HCHS2002A Saeries BOPP Tape Slitter Rewinding Machine

Max. working widths: 1.3m, 1.6m Jumb-roll unwind diameter: 750mm

Mini. slitting width: 12mm up (optional) Slitting blade: razor blade (0.2x22x60mm)

Rewind paper core: 3" (76.2mm) Max. rewind diameter: 150mm (4 shafts exchange)

Feature of HCHS2002A Saeries BOPP Tape Slitter Rewinding Machine

1. Equipped with connected unwind base, which is convenience on operationand space saving.

2. Equipped with surface type lay on roller on unwind base to make web wound out more smoothly.

3. Slitting by razor blade, which was designed to slit various film tapes.

4. Driven by one A.C motor with 3 stages type length counter to make machine stops accurately.

5. Rewind tension is controlled by clutch, it works with differential shafts to make tension on each roll the same even when the web thickness is not the same at all.

6. Finished rolls unload and paper cores reload working by core loader (HCSA105), it increases full production capacity.

Optional Part of HCHS2002A Saeries BOPP Tape Slitter Rewinding Machine

1. Core Alum. mold: it is needed when slitting different sizes, any sizes can be made on your request.

2. Unwind base: connected shaft type, jumbo-roll uplifting.

3. Auto tabber: label tape roll unwind system.

4. Slitter blade: air scroll knife (width 10mm) with firm roller and guide bar.

5. Noise reduction hood: connected unwind safety cover, hydraulic control.

- Q: What is the general packing cost of beer beverage packaging?

- A privately owned enterprise production and processing, wholesale distribution, production of various types of complete packing machine, sealing machine, packing machine, vacuum machine, sealing machine, electromagnetic machine, packing machine, mushrooms should be material, full automatic filling machine, cuff type packing machine, sending spot

- Q: What are the packing machines?

- Glass glue category of automatic and manual soft packing machine, chemical, I do not know what you are talking about? You can go and have a look.

- Q: A & B two sets of packaging machines, at the same time packaging quality of 500 kilograms of goods

- (3) large variance, indicating that this group of data volatility, variance is small, volatility is relatively stableAnswer: (1) a = x (501+500+503+506+504+506+500+498+497+495), 10=501,B = x (503+504+502+498+499+501+505+497+502+499), 10=501;(2) S2, =1/n[(501-501) 2+ (500-501) 2+... + (495-501) 2]=12.6,S2 B, =1/n[(503-501) 2+ (504-501) 2+... + (499-501) 2]=6.4;(3) a b > S2 dreams S2,The quality of R B packaging machine 10 bags of sweets is relatively stable.Comments on the subject, mainly on the average number, variance calculation, and their significance, the correct memory formula is the key to solving problems

- Q: What are the main functions of packaging machinery and equipment?

- Packaging machinery can be realized in the packaging process, including filling and wrapping,

- Q: How much is the tableware wrapping machine?What's the price of the tableware wrapping machine?

- Tableware packaging machine packaging production, simple operation and high degree of automation, high efficiency, low packing cost, save labor, reduce the damage and the characteristics of two pollution, by tableware shrink packaging is widely used in all kinds of, is a very mature model

- Q: Whether you can press paper plastic molding after PET

- Sure;Note cards must be coated with plastic oil;Can use blister sealing machine or high frequency plastic welding machine hot pressing;

- Q: Is there anyone who knows what groups of users of packaging machinery are in general?

- If automated packaging, it depends on the factory situation, should not be from the user groups to start. If a small class of cosmetics do, then he will not say to buy a more than ten thousand or hundreds of thousands of automated equipment to pack ah. Automatic packing machine is certainly need a certain amount, a certain basis will be needed, or buy a mechanical automation a month the amount of packaging takes less than one hour, then buy this station automation machinery to do what? So, according to the automatic device, we can not start from the user groups, should be considered from the size of the factory.

- Q: What is the working principle of the pillow packing machine?

- The sealing form - bag two sealing, a middle sealing surface,

- Q: Food, equipment, tools, containers, packaging materials, etc. shall comply with food safety standards or requirements

- 5009.101 determination of antimony in polyester resins and their moulding products for food containers and packaging materialsGB 13113 hygienic standard for polyethylene terephthalate moulding articles for food containers and packaging materials

- Q: Energy saving reform of packaging machine

- A) the main control circuit is composed of man-machine interface (text display), frequency converter and programmable logic controller (PLC), which constitute the control core;B) the temperature control circuit is composed of an intelligent temperature control meter, a solid state relay and a thermocouple element. The temperature control is accurate, the display is intuitive, and the setting is convenient;C) multi point tracking and detection by photoelectric switches and electromagnetic proximity sensors; 2) fully automatic pillow type working principle:With the improvement of automation, the operation, maintenance and routine maintenance of the packing machine are more convenient and simple, and the professional skill requirements of the operators are reduced. The quality of the product packaging is directly related to the temperature system, the speed accuracy of the main engine and the stability of the tracking system.

1. Manufacturer Overview

| Location | Suzhou, China (Mainland) |

| Year Established | 2006 |

| Annual Output Value | |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Oceania; Mid East; Eastern Asia; Western Europe; Central America; Northern Europe; Southern Europe; South Asia |

| Company Certifications | Certificate of Compliance |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 1-2 People |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 1,000-3,000 square meters |

| No. of Production Lines | |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

HCHS2002A Saeries BOPP Tape Slitter Rewinding Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 15 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords