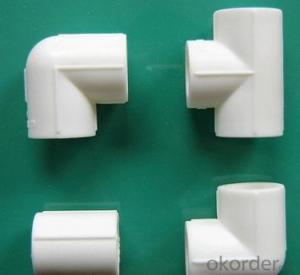

Half Inch PPR Elbows for Industrial and Agricultural Fields with High Quality

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Overview

1) Cold / hot water supply facilities for public buildings

2) Food, chemical, electronic industry pipeline networks; Such as Pipeline networks for transporting all kinds of corrosive liquids

3) Drinking water production system pipeline networks; Such as Pure water and mineral water

4) Air conditioning facility pipelines

5) Compressed gas pipeline networks for industry

6) Pipeline networks for swimming pools

7) Pipeline networks for solar energy facilities

8) Agriculture and garden production transporting systems

Application

1) Cold and hot water systems of residence and commercial buildings

2) Transportation of industrial water supply and chemical materials

3) Pure water pipe system

4) Piping networks for rainwater utilization systems

5) Irrigation agriculture and horticulture systems

6) Transportation system of drinking water production

7) Piping networks for solar plants

8) Other pipes in industry

Product Description

Pressure | Size(mm) | Pressure | Size(mm) |

PN1.25MPA | 20*2.0 |

PN1.6MPA | 20*2.3 |

25*2.3 | 25*2.8 | ||

32*2.9 | 32*3.6 | ||

40*3.7 | 40*4.5 | ||

50*4.6 | 50*5.6 | ||

63*5.8 | 63*7.1 | ||

75*6.8 | 75*8.4 | ||

90*8.2 | 90*10.1 | ||

110*10.0 | 110*12.3 |

Product Show

FAQ

1. Can you find a translator for me?

You can tell us which language you speak, we will find the translator for you, and will be together work.

2. If we want to develop some new item, but maybe we just have some ideas, how can you do?

We can make new mold base on your idea, generally, if your quantity is more enough, we can refund the mold cost to you.

3. How Long Is Delivery?

Delivery time will be 30-45 days according to order quantity.

4.What Is Our Normal Payments Terms?

Our normal payment terms: T/T, L/C or western union

- Q: What kinds of plastic pipe fittings are there? What are the various uses? And how to distinguish quality?

- Pipe fittings are very complicated, preferably with concrete points. As to the water pipe used straight, elbow, three links, three different diameter, different diameter, thread three, straight thread, thread elbow, three links, straight, elbow, as valve, pipe cap, and also have matching specifications and applications;

- Q: How do plastic pipe fittings compare to polyvinylidene fluoride (PVDF) fittings?

- Plastic pipe fittings and PVDF fittings differ in terms of their material composition and properties. Plastic pipe fittings are usually made of various types of plastic, such as PVC or CPVC, which offer good chemical resistance and affordability. On the other hand, PVDF fittings are specifically made from polyvinylidene fluoride, a highly durable and chemically resistant thermoplastic material. PVDF fittings are known for their excellent resistance to high temperatures, harsh chemicals, and UV radiation, making them suitable for demanding industrial applications. While plastic pipe fittings may be more cost-effective, PVDF fittings provide superior performance and longevity in challenging environments.

- Q: How do you choose the right size of plastic pipe fittings?

- To choose the right size of plastic pipe fittings, you need to consider the diameter and type of pipe you are using. Measure the outer diameter of the pipe and match it with the corresponding fitting size. Additionally, ensure that the fitting is compatible with the type of pipe material, whether it is PVC, CPVC, or another type. It is recommended to consult the manufacturer's specifications or seek professional advice to ensure the correct sizing and compatibility for your specific application.

- Q: Are plastic pipe fittings resistant to hydraulic pressure?

- Yes, plastic pipe fittings are generally resistant to hydraulic pressure. However, the level of resistance can vary depending on the type and quality of the plastic used. It is important to choose fittings that are specifically designed and rated for hydraulic applications to ensure optimal performance and safety.

- Q: Are plastic pipe fittings suitable for pharmaceutical manufacturing?

- Yes, plastic pipe fittings can be suitable for pharmaceutical manufacturing. They offer various advantages such as chemical resistance, low cost, easy installation, and flexibility. However, it is essential to ensure that the chosen plastic material and manufacturing processes comply with the industry's strict quality and safety standards to prevent any potential contamination risks.

- Q: Are plastic pipe fittings resistant to seismic activity?

- Yes, plastic pipe fittings are generally resistant to seismic activity. They have the ability to flex and withstand ground movement during earthquakes, reducing the risk of damage or rupture. This makes plastic pipe fittings a reliable choice for seismic-prone areas.

- Q: Can plastic pipe fittings be used for waste disposal systems?

- Yes, plastic pipe fittings can be used for waste disposal systems. Plastic fittings are commonly used in plumbing systems for their durability, corrosion resistance, and ease of installation. They are suitable for both residential and commercial waste disposal systems, effectively transporting waste materials to the sewer or septic tank.

- Q: Can plastic pipe fittings be used for water supply in remote areas?

- Yes, plastic pipe fittings can be used for water supply in remote areas. Plastic pipes and fittings are lightweight, easy to transport, and resistant to corrosion, making them suitable for remote locations where traditional materials may be difficult to access. Additionally, plastic fittings are often cost-effective and require minimal maintenance, making them a practical choice for water supply systems in remote areas.

- Q: Can plastic pipe fittings be used for process water systems?

- Yes, plastic pipe fittings can be used for process water systems. Plastic fittings are commonly used in process water systems due to their corrosion resistance, durability, and cost-effectiveness. They are also lightweight and easy to install, making them a popular choice for various applications in process water systems.

- Q: The difference between the hot melt connection and connection to electricity

- Electric melting needs electric melting pipe fittings, copper wire inside, copper wire electrify, pipe inner wall and pipe outer wall are heated and melted and bonded in one piece. Hot melt is the cross section of pipe material heated, then butt joint

Send your message to us

Half Inch PPR Elbows for Industrial and Agricultural Fields with High Quality

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords