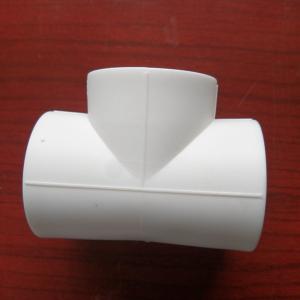

Plastic Pipe Push Fittings PPR Reducing Tee for Landscape Irrigation Drainage System

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PPR Reducing Tee Plastic Pipe Fittings

Mainly used to connect civil construction, industrial, agricultural and landscape irrigation drainage system PE pipes

Main Features of PPR Reducing Tee Plastic Pipe Fittings

1, health, non-toxic: the various parts of the pipeline system consists of PP-R pipes and fittings constituted can be completely non-toxic, health indicators in line with GB / T17219 standards.

2, does not rust: PH value can withstand a wide temperature range, in the range of 1 to 14, a high concentration of acid and alkali corrosion.

3, wear-resistant, non-fouling: PP-R pipe and tube inner wall smooth, uniform flow resistance is small and does not scale.

4, reducing vibration and noise: PP-R pipe has excellent insulation properties, can significantly reduce the vibration and noise caused by the flow of liquid.

5, anti-cracking: PP-R materials excellent elasticity makes pipes and fittings sectionally With frost expansion of the liquid together without bursting.

6, anti-condensation, heat loss is small: PP-R material is a poor thermal conductor, reduces condensation and reduce heat loss less.

7, anti-electric corrosion: PP-R material is a poor conductor of electricity can avoid corrosion. Complete specifications: 10-30 optional

Pictures of PPR Reducing Tee Plastic Pipe Fittings

- Q: Are plastic pipe fittings suitable for marine applications?

- Yes, plastic pipe fittings can be suitable for marine applications. They are commonly used in various marine systems, such as plumbing, sewage, and cooling systems, due to their corrosion resistance, lightweight nature, and durability. Additionally, plastic fittings are often more cost-effective compared to their metal counterparts and can withstand the harsh conditions and corrosive environment found in marine applications.

- Q: Can plastic pipe fittings be used for oil refinery processes?

- Yes, plastic pipe fittings can be used for certain oil refinery processes, particularly those that involve non-corrosive or non-hazardous fluids at lower pressures and temperatures. However, for processes involving corrosive chemicals, high temperatures, or high pressures, it is recommended to use more durable materials such as stainless steel or other metal alloys.

- Q: Are plastic pipe fittings prone to clogging?

- Plastic pipe fittings are generally not prone to clogging, as they have smooth interiors that allow for the smooth flow of water or other fluids. However, clogging can occur if foreign objects or debris enter the pipe system or if the fittings are improperly installed or damaged. Regular maintenance and proper installation can help prevent clogging issues in plastic pipe fittings.

- Q: Do plastic pipe fittings require any special anchoring or bracing?

- Yes, plastic pipe fittings generally do not require any special anchoring or bracing. They are designed to be lightweight and flexible, and can typically be supported by the plumbing system itself. However, in certain situations or when subjected to high pressure or vibrations, additional support or bracing may be necessary to ensure the stability and integrity of the fittings.

- Q: What are the common jointing methods for plastic pipe fittings?

- The common jointing methods for plastic pipe fittings include solvent welding, threaded connections, compression fittings, and push-fit or snap-fit connections.

- Q: Are plastic pipe fittings resistant to high-pressure steam?

- Yes, plastic pipe fittings are generally not resistant to high-pressure steam.

- Q: Can plastic pipe fittings be used in renewable energy systems?

- Yes, plastic pipe fittings can be used in renewable energy systems. Plastic pipes and fittings are commonly used in various renewable energy applications such as solar water heaters, geothermal systems, and biomass heating systems. They offer advantages such as corrosion resistance, lightweight construction, and ease of installation, making them suitable for use in renewable energy systems.

- Q: Can plastic pipe fittings be used for chemical storage systems?

- No, plastic pipe fittings should not be used for chemical storage systems as they may not be able to withstand the corrosive nature of certain chemicals and can lead to potential leaks or failures in the system. It is recommended to use fittings specifically designed for chemical storage applications, such as those made from corrosion-resistant materials like stainless steel or high-density polyethylene (HDPE).

- Q: Do plastic pipe fittings require any special threading or grooving?

- No, plastic pipe fittings do not require special threading or grooving. They are typically designed to be easily joined together using compression fittings, solvent welding, or push-fit connections.

- Q: Can plastic pipe fittings be used in reverse osmosis systems?

- Yes, plastic pipe fittings can be used in reverse osmosis systems. Plastic fittings are commonly used in these systems due to their durability, resistance to corrosion, and cost-effectiveness. They provide a reliable and efficient connection between different components of the system, ensuring proper functioning of the reverse osmosis unit.

Send your message to us

Plastic Pipe Push Fittings PPR Reducing Tee for Landscape Irrigation Drainage System

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords