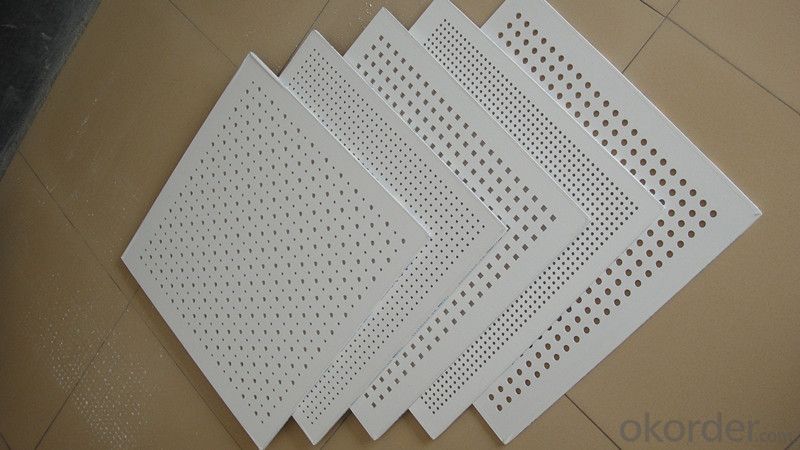

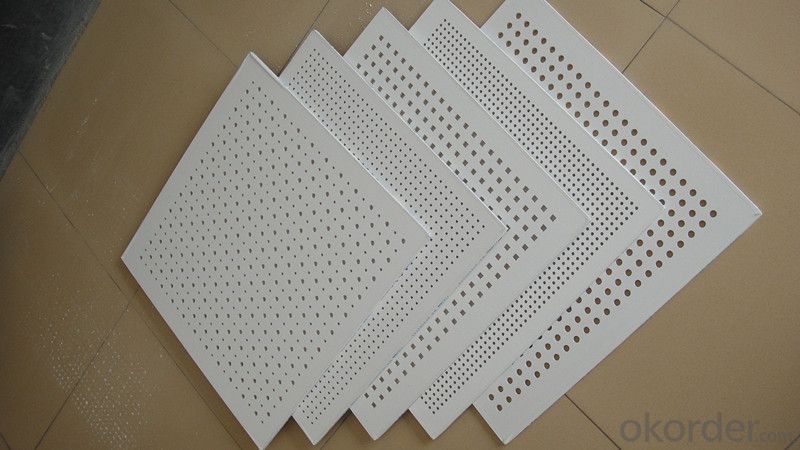

Gypsum Board Good quality Low Price Acoustic Perforated

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Gypsum Board is typically made of an inner core of gypsum that is encased in paper.

The strong laminating paper encasing the board can accommodate virtually any type of decorative

treatment(paint,polish and varnish,etc).

Product Applications:

Mainly used in those places with highg-rade decorationwhere strict acoustic environment is crucial,

such as theater, concert hall, museum, library, hearing room, gallery, auction house, gymnasium,

lecture hall, multifunctional hall, hotel lobby, hospital, shopping mall, piano practice room,etc.

Product Advantages:

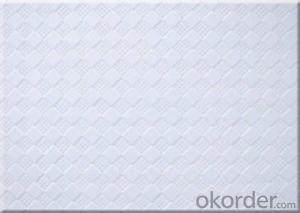

1. Design Type: Flat glossy and clear

2. So many patterns can meet your needs

3. Environmental protection

4. The product never fade easily

5. Easy to clean and install

6. High quality, good service and good price

Main Product Features:

MATERIAL:GYPSUM BOARD

SURFACE:PAPER FACED

EDGE:SQUARE,TARERED

DENSITY:AS PER GB/T9775-1999

BREAKING STRENGTH:AS PER GB/T9775-1999

ANTI-FIRE FUNCTION:<30 MINS AS PER GB8624-1997

COMBUSTION PERFORMANCE:NON-COMBUSTIBLE MATERIAL

SIZE TOLERANCE:LENGTH/WIDTH<+-2.0mm< span="">

MOISTURE CONTENT:<2%< span="">

HEAT COEFFICIENT:0.16-0.18

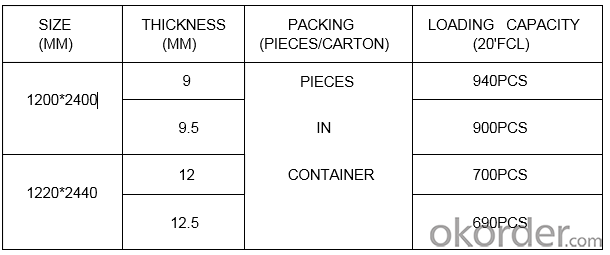

Product Specifications:

FAQ:

•Q: How to calculate product transportation cost?

A: According to the products weight or volume, according to the logistics company quotation.

•Q: Do you provide free sample? And how many days it will take?

A: Yes, we can provide free sample, of course it is better if you would like to pay the courier charge.

•Q: What's our price?

A: We provide resonable quotation.

Images:

- Q: Gypsum board to do the wall above is the wallpaper or brush latex paint price is reasonable

- Wallpaper prices vary, latex paint may be more reasonable, the effect is certainly not good wallpaper!

- Q: What are the applications of building gypsum in architecture?

- Building plaster applications: There are many types of gypsum products in the building. Our main products are gypsum block, gypsum board, hollow gypsum board, fiber gypsum board and gypsum plaster.

- Q: Gypsum board ceiling installation corner must be seven-shaped

- You should say is mineral wool gypsum board bar (specifications 600 × 600 or 600 × 1200), the corner must be used piece "L" type, or take the sub-bone and edge aluminum. Norms also have this requirement.

- Q: Decorative gypsum board partition with what the best sound insulation cotton? Mineral rock wool and glass wool.

- Rock wool and glass wool on the overall performance of almost, are brittle fiber composition, need to get a better sound volume, the need for higher density materials, usually 80KG per cubic meter of use more. The price range is 40-60 yuan per square meter. This material can cause skin irritation, dust can cause respiratory irritation. So the construction should pay attention to the construction workers physical protection, the material must be completely closed to the wall inside. If it is a hole in the ceiling must not use glass wool. Construction methods are the same, directly on the keel space, outside the sealing plate.

- Q: Waterproof gypsum board water absorption

- Water-resistant gypsum board water absorption of the national standard is <10%, as you said the gap in the gypsum board inhaled a lot of water, it is definitely not water-resistant gypsum board, the current market, some manufacturers with moisture gypsum board to muddle through (such as domestic dragon Brand has this situation), because the moisture-proof paper gypsum board only face paper added to the hydrophobic agent, and gypsum core is not.

- Q: What is the effect of kitchen gypsum board?

- No, this really did not do, the kitchen with aluminum buckle board, the cost is cheap, the effect is also good!

- Q: Gypsum board and steel structure connection with what

- A little bit of the use of self-tapping nails.

- Q: Gypsum board brush latex paint how to deal with yellow

- If only the surface of the latex paint, then you can directly continue to use latex paint roller brush to cover; if there is a crack or depression on the wall, then you can put these places putty layer, and then paste the bandage and filled with gypsum powder putty , And then ordinary putty leveling and polished smooth, and finally brush on the latex paint on the line. Newly renovated walls can be partially patched (brush latex paint), a long time, then the whole wall will have to brush again or twice, otherwise there will be traces of repair.

- Q: Is it possible to use a gypsum board ceiling in the bathroom?

- Waterproof gypsum board refers to the slab in the United States under the ASTM standard for waterproofing test, the water absorption rate of 5%, that can be used for large areas of humidity, such as the bathroom, shower room and kitchen, the board is in the gypsum core Material to add a quantitative waterproofing agent, so that the plaster itself has a certain waterproof performance. In addition, gypsum board paper is also waterproof, so this is a better use of a wider range of plate. But this board can not be directly exposed to the wet environment, nor direct water immersion for a long time.

- Q: How to distinguish between true and false

- Each keel of the light steel keel has a stamped BNBM mark. And a watermark: dragon brand light steel keel and a certain model or dragon brand furniture keel. There are labels on it. Then, the dragon brand light steel keel surface is very oily, is to prevent rust, and the process is better. The strip color does not look particularly bright and is not particularly blunt The radian of the corners is perfect. Oh, I only know so much, I hope to help you.

Send your message to us

Gypsum Board Good quality Low Price Acoustic Perforated

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords