Gypsum Board Good quality Low Price Acoustic Perforated

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Gypsum Board is typically made of an inner core of gypsum that is encased in paper.

The strong laminating paper encasing the board can accommodate virtually any type of decorative

treatment(paint,polish and varnish,etc).

It can be directly attached to existing surfaces or frames with adhesives, nails or screws.

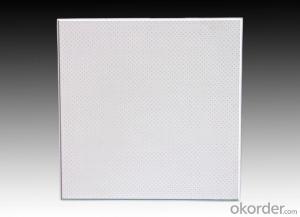

Gypsum Board is widely used as a covering material for ceilings and walls in home decoration.

Product Applications:

Mainly used in those places with highg-rade decorationwhere strict acoustic environment is crucial,

such as theater, concert hall, museum, library, hearing room, gallery, auction house, gymnasium,

lecture hall, multifunctional hall, hotel lobby, hospital, shopping mall, piano practice room,

conference room, studio, recording room, KTV room, bar, industrial workshop, machine room, etc.

Product Advantages:

1. Design Type: Flat glossy and clear

2. So many patterns can meet your needs

3. Environmental protection

4. The product never fade easily

5. Easy to clean and install

Main Product Features:

MATERIAL:GYPSUM BOARD

SURFACE:PAPER FACED

EDGE:SQUARE,TARERED

DENSITY:AS PER GB/T9775-1999

BREAKING STRENGTH:AS PER GB/T9775-1999

ANTI-FIRE FUNCTION:<30 MINS AS PER GB8624-1997

COMBUSTION PERFORMANCE:NON-COMBUSTIBLE MATERIAL

SIZE TOLERANCE:LENGTH/WIDTH<+-2.0mm< span="">

MOISTURE CONTENT:<2%< span="">

HEAT COEFFICIENT:0.16-0.18

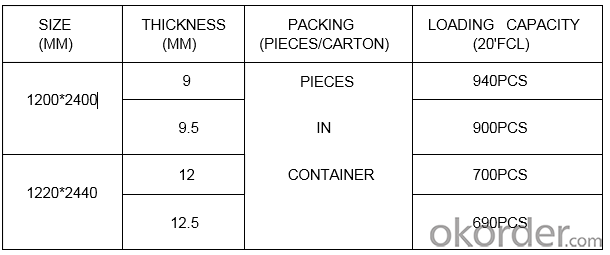

Product Specifications:

FAQ:

•Q: How to calculate product transportation cost?

A: According to the products weight or volume, according to the logistics company quotation.

•Q: Do you provide free sample? And how many days it will take?

A: Yes, we can provide free sample, of course it is better if you would like to pay the courier charge.

•Q: What's our price?

A: We provide resonable quotation.

•Q: How about our quality?

A: We provide international quality.

Images:

- Q: Can Feifei gypsum board price

- The prices of the regions are different, depending on where you are.

- Q: Decorative gypsum board partition with what the best sound insulation cotton? Mineral rock wool and glass wool.

- Sound insulation effect is good, the construction is simple glass wool, the price thing is the latter, but no test report, you use, no quality assurance.

- Q: Waterproof gypsum board water absorption

- Water-resistant gypsum board used in the environment is the humidity of the environment, it has a certain water absorption, but through the air circulation can be released as long as your environment is not constant at 90 degrees Celsius 90% humidity.

- Q: I would like to ask how much small gypsum board machinery

- If it is a paper gypsum board production line, the equipment investment should be about 200 million (less developed areas, the smallest scale) but the operating costs are huge, are high energy-consuming products (coal, electricity), especially equipment debugging period is simply burning money If it is a lot of the cost of gypsum ceilings, equipment and the like is very cheap, but this product is not suitable for the market.

- Q: Paper gypsum board non-stick paper and resurgence is what reason

- Board ripples, pull ditch and other uneven phenomenon. The generation of such problems is related to paper indicators, process control and other issues. First, the paper factor. The amount of moisture, is not uniform, so that the paper is tight, different thickness, different water absorption, where the water is large, wet expansion is small, small water, wet expansion, in the dry The area of ??serious contraction, and the surrounding areas of less dry dry shrinkage, which resulted in the expansion of the paper, contraction is inconsistent, and cause ripples or pull ditch. Second, the problem of process equipment. The flatness of the molding platform is not enough or the adjustment is not in place, the same can cause the board uneven, this cause the problem is more concentrated, easy to find, but through the improvement of the process equipment to achieve the improvement of flatness of the board. Third, material and material fluctuations are also one of the important causes of uneven board. Due to fluctuations in raw materials, additional materials, and fluctuations in the milling process, it is inevitable that changes in the coagulation time and lift of powder and slurry are inevitable, but if the fluctuation is too frequent or fluctuating, Resulting in the subsequent process of the process is difficult to timely adjustment and control, can also lead to board groove and other undesirable phenomena.

- Q: What is the degree of grinding when the wall is polished?

- The first putty wiping flat, at least wiping 2 times, polished when a hand holding a light bulb, the wall of the small flaws in the light will be very clear, to focus on the flaws destroyed, a large area of a grinding and over, this will save time and energy. Brush the first paint, and then light inspection, the little bit to make up on the putty, polished smooth, and then brush 2 paint, so that even the wall in the downlight lighting will be perfect.

- Q: I installed the lights on the gypsum board on the screw, not the kind of embedded lights

- Looking for gypsum board ceiling when the position of the dragon skeleton, in the position of the keel installed lights, and now the lamps are relatively light as long as you can screw the screw on the keel it certainly no problem.

- Q: 9 meters, the closet to do 2.4 meters high and then gypsum board cap or directly to the top of the rough layer height of about 2.9x meters

- It is recommended that the following wardrobe do 220cm high overall moving door, do 60cm high top cabinet (storage cabinet) with cabinet board to do the door, especially practical.

- Q: Gypsum board wall batch of gray do not brush latex paint can be directly posted wallpaper?

- Under normal circumstances, gypsum board wall after the release of latex paint is excessive, but there are outside the situation. For example, to do a large exhibition wall, if you must use the gypsum board wall putty putty, the surface to brush latex paint, and wallpaper is only part of the area, and the use of decorative wall after the demolition, you can put in the putty, the whole wall Brush latex paint, then stickers wallpaper. The specific use of the actual needs of the operation, with less cost and risk access to quality and efficient engineering quality is a good construction program.

- Q: Gypsum board hanging before the top and the wallpaper before the paste, must be putty putty?

- Process flow Grass-roots treatment → full scratch putty twice → the bottom of the paint → middle paint twice → latex paint spray → cleaning.

Send your message to us

Gypsum Board Good quality Low Price Acoustic Perforated

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords