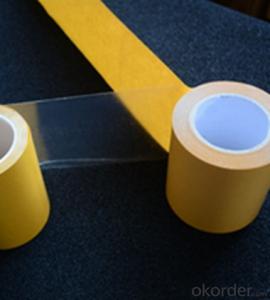

Unibond Strong Gum Tapes Hot Melt Waterproof Single-Sided

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 500000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Product details

| Type | Self adhesive products |

| Material | Soft PVC/PET, glossy paper |

| Color | White,clear,transparent,colourful |

| Surface | Smooth,glossy or frosted,matte,dull ploish |

| Adhesive type | Acrilic glue or slovent |

| Adhesive feature | Permanent or removable |

| Thickness | 40/50/70/80/100/120/150 micron |

| Liner paper | 140/160/180gsm white PE laminating single silicon release paper. or 62gsm glassine liner |

| Printing method | Offset printing,screen printing,flex printing |

| Width | Max 1070mm,1200mm,1540mm Length can be customized |

| Packaging | In sheet:100/200 sheets/ream, 50/100 reams/pallet. Strong PE coated kraft paper, stretch film, plastic fasten belt, strong pallet |

| Usage | For various of label material / decorative film/wall sticker/blackboard sticker |

2.Packaging & Delivery

Packaging Details:

48mm self adhesive gummed kraft paper tape packing:

In sheet:100/200 sheets/ream, 50/100 reams/pallet.Strong PE coated kraft paper, stretch film, plastic fasten belt, strong pallet

In roll:packed with strong sea worthy poly wood pallet for exporting standard

Delivery Detail:

Deliver within 7~14 days after advance payment

3.NOTE

1,Customers' logos and designs are welcome(OEM)

2,High quality and competitively quote

3,Standard packing

4,Please contact us for more details

4.Company information

CNBM International Corporation (CNBM International) is the most important trading platform of CNBM Group Corporation, a state-owned company under the direct supervision of State-owned Assets Supervision and Administration Commission of the State Council.

We specilized in Duct tape, Masking tape, Double sided tissue tape, PET tape, Foam tape, PVC tape, Warning tape, Fiberglass tape…Now we have exported our products to over 30 countries and regions like Europe ,South / North America ,Southeast Asia etc and gained customer's respect and continued businesses. Based on our good quality , reasonable price, good after-sale service, we enjoyed good reputation in the international market.

Warmly welcome your any inquiries or request ! You will be impressed by our superior quality, quick delivery date and attractive price. Contact us now!

5.product show

- Q: Belt business is a big profit

- The use of a large amount of market potential, is ideal for the laid-off unemployed, second occupation and three industrial investment and set up factories.As everyone knows, tape product market sales, high profit, brand demand is not high, but because of the production equipment investment is too large to produce user feel weak, small investment can not intervene. With the continuous development of China's economy, especially the rapid development of the packaging industry in recent years, the market of the tape demand is huge. Based on our technical staff on the investigation, combined with the domestic and foreign advanced technology, the bold exploration and innovation, developed a multifunctional energy-saving tape production equipment of various specifications of success. The series of indicators is much higher than that of the old production equipment. The equipment, reliable performance, convenient operation, energy saving, low cost, no noise. The tape produced with high strength, high gloss, good sealing, no pollution, so that the majority of users to achieve the dream. The founder of tape with low cost, the scale of the students The desire of the factory has been well received by the industry and people from all walks of life

- Q: How do I prevent packaging tape from wrinkling?

- To prevent packaging tape from wrinkling, make sure to apply it smoothly and evenly, without any folds or creases. Start by holding the tape at a slight angle and pressing it firmly onto the surface, while gradually unrolling it. Avoid tugging on the tape too forcefully, as this can cause it to wrinkle. Additionally, using a good quality tape dispenser or a handheld tape gun can help ensure a smooth application.

- Q: What are the benefits of using UV-resistant packaging tape?

- UV-resistant packaging tape offers numerous advantages. Firstly, it is specifically designed to endure prolonged exposure to sunlight, preventing it from deteriorating or degrading. This is particularly crucial when shipping or storing items outdoors or in areas with direct sunlight. With UV-resistant tape, packages can remain securely sealed for extended periods as it maintains its adhesive properties and structural integrity. Furthermore, UV-resistant packaging tape safeguards the contents of packages from UV ray damage. Sunlight can cause materials like paper, fabrics, or plastics to fade, discolor, or degrade. By utilizing UV-resistant tape, these items are shielded from the harmful effects of UV rays, preserving their quality and appearance. Moreover, UV-resistant packaging tape boasts long-lasting adhesion. Unlike regular tape, which may lose its stickiness over time when exposed to sunlight, UV-resistant tape is specially formulated to bond tightly and securely to various surfaces. This reliable adhesion minimizes the risk of packages opening or items sustaining damage during transit. Additionally, UV-resistant packaging tape provides peace of mind for both senders and recipients. By opting for tape that is resistant to UV rays, businesses and individuals can ensure that their packages arrive in the same condition they were sent, enhancing their professional image and customer satisfaction. This advantage is particularly vital when shipping valuable or delicate items that require extra protection. In conclusion, UV-resistant packaging tape offers enhanced durability, protection against UV damage, long-lasting adhesion, and increased confidence in package integrity. By selecting UV-resistant tape, individuals and businesses can effectively safeguard their packages and their contents, even when exposed to prolonged sunlight.

- Q: Can packaging tape be used for sealing perishable food items?

- Using packaging tape to seal perishable food items is not recommended. This is because packaging tape is typically made of materials like polypropylene or PVC, which are not suitable for food safety and may contaminate the food. Additionally, packaging tape is not designed to create an airtight seal, which is essential for preserving the freshness and preventing spoilage of perishable food items. To ensure the safety and quality of perishable food items, it is advisable to use appropriate food-safe sealing methods such as ziplock bags, airtight containers, or food-grade cling wrap.

- Q: Sealing tape sales skills and knowledge, please explain to professionals! Help, please

- 6, you should make yourself look like a good product.7 dress up for success and dress for victory.Investment in the image of salespeople is the most important investment for sales staff.

- Q: What is the best way to apply packaging tape?

- The best way to apply packaging tape is to first ensure that the surface is clean and dry. Start by holding the tape dispenser at a slight angle and pressing firmly on the surface, moving the dispenser smoothly in a straight line. Avoid stretching or folding the tape as it can weaken its adhesive properties. Finally, use a sharp object to cut the tape cleanly, ensuring a secure and professional seal.

- Q: Can packaging tape be used for sealing retail or product packaging?

- Certainly, retail or product packaging can be effectively sealed using packaging tape. Specifically designed for securely sealing boxes and packages, packaging tape offers a durable seal. Its usage is widespread across various industries, including retail, e-commerce, and product packaging. Made from robust adhesive material, packaging tape guarantees the package remains sealed throughout transportation and handling. Its ease of use allows for quick and efficient application. Moreover, packaging tape comes in a range of sizes and strengths, enabling it to meet diverse requirements for different types of retail or product packaging. In conclusion, packaging tape proves to be a dependable and efficient choice for sealing retail or product packaging.

- Q: Is packaging tape resistant to mold or mildew?

- Packaging tape is generally resistant to mold or mildew. Typically, materials like polypropylene or vinyl, which do not offer a suitable environment for mold or mildew growth, are used to make most packaging tapes. These materials are impermeable and waterproof, preventing moisture from penetrating and creating conditions favorable for mold or mildew to thrive. Moreover, packaging tape often has a mold or mildew-resistant adhesive coating. Nevertheless, it is worth mentioning that if the tape is applied to a surface already contaminated with mold or mildew, it may not hinder further growth or eradicate the existing mold or mildew.

- Q: Can packaging tape be used for sealing gardening or outdoor equipment?

- Yes, packaging tape can be used for sealing gardening or outdoor equipment. It provides a strong adhesive bond and can effectively seal boxes or other packaging materials used for storing or transporting gardening or outdoor equipment. However, it is important to consider the durability and weather resistance of the tape to ensure it withstands outdoor conditions.

- Q: Does packaging tape have a specific shelf life?

- Yes, packaging tape does have a specific shelf life. The shelf life of packaging tape typically depends on the type and quality of the tape. However, most packaging tapes have a shelf life of around 1 to 2 years if stored properly in a cool, dry place. It is always recommended to check the manufacturer's guidelines for specific information on the shelf life of a particular packaging tape.

Send your message to us

Unibond Strong Gum Tapes Hot Melt Waterproof Single-Sided

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 500000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches