Green/White/Blue PVC Conveyor Belt PU Conveyor Belt Roll Material

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

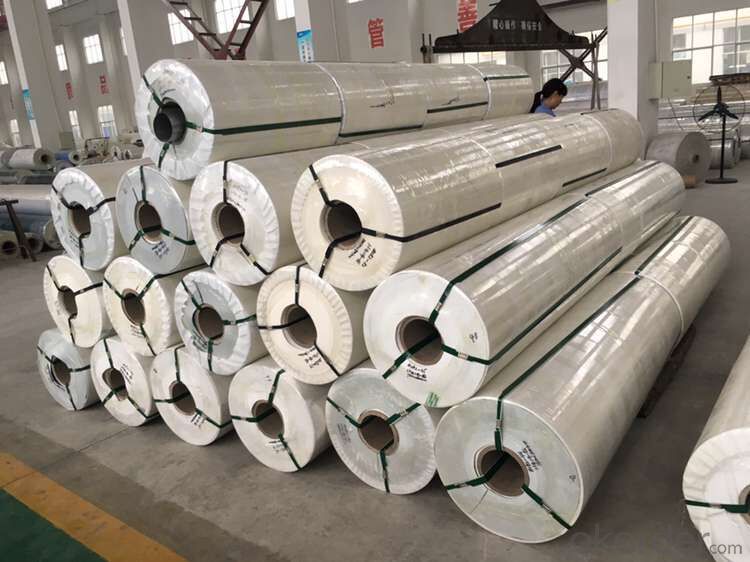

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Green/White/Blue PVC Conveyor Belt PU Conveyor Belt Roll Material

We can divide the conveyor belt into three categories: PVC conveyor belt, PU conveyor belt and some special material, such as silica gel, rubber.

conveyor belt fabric layers: A layer of cloth and a layer of glue, two layers of cloth and two layers of glue, three layers of cloth and three layers of glue, and so on. It can be customized according to your requirements.

Colors: red, yellow, green, blue, gray, white, black, blue, green, transparent (in general we have)

Thickness: PVC (1~7mm) PU (0.8~4mm)

Appearance: flat surface, diamond pattern, lawn pattern, golf pattern etc.

PVC light industry conveyor belt

Suitable for light industrial, packing light industrial, transport for tobacco, tea, pieces vegetable, fruit and so on. Also can be used in airport, post office, storage and etc.

PU light industry conveyor belt

Widely used in food industry. Transport the material in bulk, canning and packed In box. The material includes grain, cooky, candy, vegetables, fruit, fowl, meat and so on.

Also widely used in soft material industry. Used in those field, including tobacco, electron, textile, printing and dyeing, machine manufacturing, print and package, paper processing, pottery, marble, wood processing,car shell molding, cable fishing wire, aluminium parts processing and etc.

Subsequent machining technology: it can add baffle, skirt, sponge, guide bar.

Feature Food PVC Conveyor Belt:

*Anti-static and non-conductive

*Food quality types to FDA standards

*Resistance to abrasion, oils, fats and chemicals

*Surfaces with low, medium or high coefficient of friction

*High transverse rigidity and dimensional stability

* Low noise (LdB belts)

* Working temperature ranges from -10 to 80Deg.C

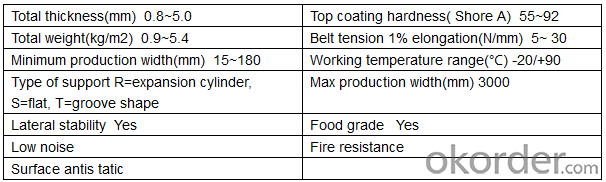

Food PVC/PU Conveyor Belt Specification

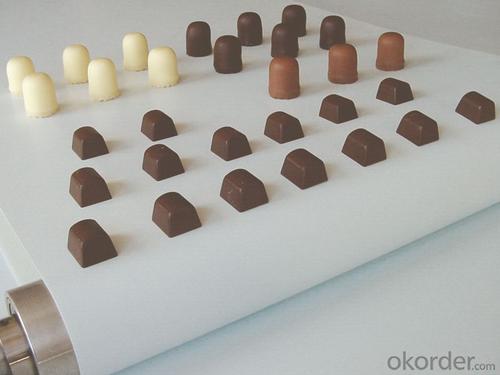

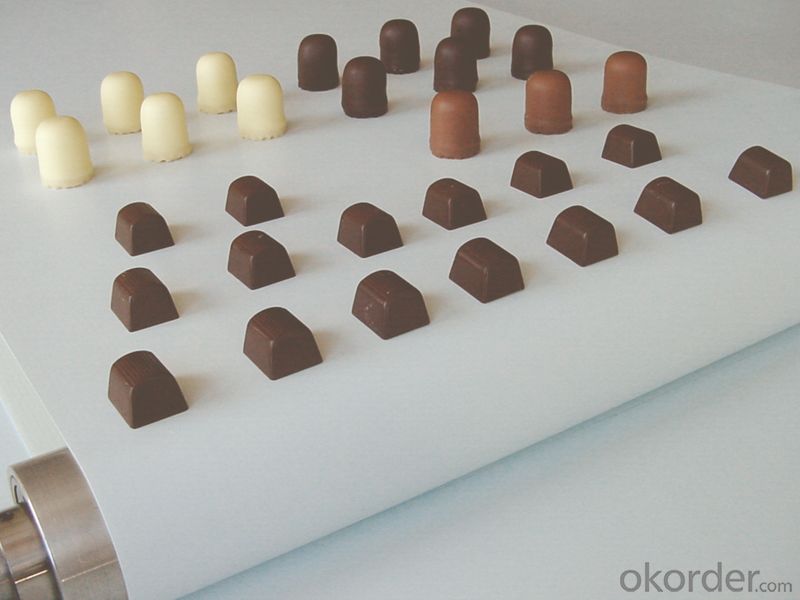

Photos of Food PVC Conveyor Belt

FAQ

Can you give me discount?

Yes, of course. If you talk with us, you’ll get more.

Will you send me free sample?

Yeah, she'd love to; can you buy her a ticket?

Do you like to accept small orders?

We enjoy to grow up together with all our clients, whatever big or small.You will become bigger and bigger to be with us.

Buyer attention

If you are interested in our products and company, please leave a message here or E-mail to us, We will reply you without any delay.

- Q: Why should I granulate before injection? What's the advantage of granulation?

- Direct crushing material can also be used, but the direct crushing of the material due to uneven particle size, resulting in uneven storage process, the process becomes more unstable. And granulation, the particles are generally more homogeneous, and later injection molding process is relatively stable! As for the difference between granulation and injection: This is the two process, granulation is a number of waste plastics through melting, extrusion, in the cutting machine to cut into granular. During the granulation process, some additives can be added to improve the performance of waste plastics. Something like a toughening agent. Plastic injection is the formation of plastic products by melting the plastic material and then by pressing it into the mold. Popular to say is: injection molding is the raw material into plastic products, and granulation is to make plastic products again "raw material""!

- Q: How does an olive net affect the tree health and growth?

- An olive net can positively affect the tree health and growth by providing protection against pests and wind damage. It helps prevent birds and insects from feeding on the olives, reducing the risk of diseases and promoting healthier fruit production. Additionally, the netting acts as a shield against strong winds, minimizing the potential for branch breakage or tree stress. Overall, the use of an olive net contributes to a healthier and more productive olive tree.

- Q: How do olive nets prevent damage from diseases transmitted through soil?

- Olive nets act as a physical barrier, preventing direct contact between the soil and the olive tree, thereby reducing the risk of diseases transmitted through soil.

- Q: How do you clean an olive net?

- To clean an olive net, it is recommended to first remove any debris or loose olives from the net by gently shaking or brushing them off. Then, rinse the net with water and use a mild detergent or soap to scrub away any remaining dirt or stains. After cleaning, rinse thoroughly to remove any soap residue and allow the net to dry completely before storing or reusing.

- Q: Can olive nets be used for olive trees in regions with high disease incidence?

- Yes, olive nets can be used for olive trees in regions with high disease incidence. Olive nets are commonly used as a protective measure to prevent pests and diseases from affecting the olive trees. They create a physical barrier that keeps insects and pathogens away from the trees, reducing the risk of infection. However, it is important to note that olive nets alone may not be sufficient to completely eliminate disease incidence in regions with high prevalence. It is recommended to combine netting with other disease management practices, such as regular pruning, proper irrigation, and the use of disease-resistant olive tree varieties, for better control of diseases.

- Q: Can olive nets be used for olive tree pollination management?

- No, olive nets cannot be used for olive tree pollination management. Olive trees are primarily wind-pollinated, and their flowers do not require insects or other external factors for pollination.

- Q: Can olive nets be used in orchards with other fruit trees?

- Yes, olive nets can be used in orchards with other fruit trees. Olive nets are versatile and can be used to protect various types of fruit trees from birds and other pests. They are effective in preventing damage to the fruit and can be easily installed and removed.

- Q: How do olive nets affect the labor required for olive harvesting?

- Olive nets can significantly reduce the labor required for olive harvesting. These nets are spread under the olive trees, allowing the olives to fall onto them when they are shaken or picked from the branches. The nets then collect the fallen olives, making it much easier and faster to collect a large quantity of olives. This eliminates the need for manual picking and reduces the labor-intensive process of bending down to collect individual olives from the ground. Overall, olive nets streamline the harvesting process, making it more efficient and reducing the labor involved.

- Q: How do olive nets prevent sunburn damage to olives?

- Olive nets prevent sunburn damage to olives by providing shade and reducing direct exposure to sunlight. The nets act as a barrier, blocking a significant amount of harmful UV rays and minimizing the risk of sunburn.

- Q: New plastic products have a strong taste, how to remove?

- Method: the use of ventilation air flow away dilution plastic taste, can also use the electric fan to blow, or outdoor fresh air to the mountains "bubble". Need to remind is, some people use negative oxygen ion generator to control low concentration air pollution, but governance effect is not satisfactory, negative oxygen ion is easy to change into ozone, cause two pollution.

Send your message to us

Green/White/Blue PVC Conveyor Belt PU Conveyor Belt Roll Material

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords