GRE Pipe for Oil Exploration and Transportation

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 Meters m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of GRE Pipes for Oil Exploration and Transportation

Lightweight and easy to handle and install, GRE pipes have a smooth internal surface that reduces friction and enables a high pipe flow capacity. The low thermal conductivity of GRE pipes relative to steel (only one percent of steel values) minimises the cost of insulation and heat loss. Another major benefit of GRE pipes is that, once they are installed, they are virtually maintenance-free.

GRE pipes are well suited for environments where corrosion resistance is required at a reasonable price.

Main uses include petrochemical process lines, oil and gas systems, fire-fighting systems, offshore and onshore systems, and ship and marine applications.

GRE pipes are available in diameters ranging from DN 25 to DN 1,000 mm.

Advantage of GRE Pipes for Oil Exploration and Transportation

Excellent chemical resistance property

Able to withstand high pressur and high termperature

Higher transportation efficiency

Ligh-weight easy to install

Designable electrical property

Lower abrasion coefficient

Able to connect with steel pipe

Smoothly inner wall, no scaling, no waxing, not prone to clogged

Longer service life that is 4 to 5 times compare to steel pipe(about 20 years)

Low maintenance cost

Application of GRE Pipes for Oil Exploration and Transportation

Injection and delivery pipeline

Crude oil

Potable water

Brine transport pipeline

Oilfield sewage, chemical sewage and wastewater process pipeline

Fire water pipeline

Storage tank connector

Polymer solution transmission pipeline

Petrochemical process pipeline

Geothermal pipes

Slotted liner and sieve vessels

Natural gas

CO2 or H2S

CO2 or H2S gathering and transport lines

Specification of GRE Pipes for Oil Exploration and Transportation

Anhydride GRE pipe | |||||||||

Diameter | Pressure | ID | OD | Threading | Wall Thickness | Weight | Min. Radius | Length/pc | |

mm | (in) | (Mpa) | (mm) | (mm) | (in) | (mm) | (Kg/pc) | (m) | (m) |

DN40 | 1 1/2 | 7 | 38.2 | 41.8 | 1.9 | 1.78 | 6.2 | 30 | 9.14 |

8.5 | 38.2 | 41.8 | 1.78 | 6.5 | 30 | ||||

10 | 38.2 | 42.3 | 2.04 | 7.5 | 30 | ||||

12 | 38.2 | 43.2 | 2.48 | 7.8 | 30 | ||||

14 | 38.2 | 44 | 2.92 | 8 | 32 | ||||

16 | 38.2 | 45 | 3.38 | 9.8 | 32 | ||||

18 | 38.2 | 45.9 | 3.86 | 10 | 34 | ||||

20 | 38.2 | 46.9 | 4.34 | 11.3 | 34 | ||||

22 | 38.2 | 47.9 | 4.85 | 13 | 36 | ||||

25 | 38.2 | 49.5 | 5.63 | 14.6 | 38 | ||||

DN50 | 2 | 5.5 | 50.6 | 54.1 | 2 3/8 | 1.78 | 8.9 | 40 | 9.14 |

7 | 50.6 | 54.3 | 1.86 | 9.2 | 40 | ||||

8.5 | 50.6 | 55.1 | 2.27 | 10.7 | 42 | ||||

10 | 50.6 | 55.9 | 2.7 | 11 | 42 | ||||

12 | 47.9 | 54.1 | 3.1 | 11.6 | 42 | ||||

14 | 47.9 | 55.2 | 3.67 | 13.3 | 42 | ||||

16 | 47.9 | 56.4 | 4.24 | 15.2 | 44 | ||||

18 | 47.9 | 57.6 | 4.84 | 17.1 | 44 | ||||

20 | 47.9 | 58.8 | 5.45 | 17.4 | 44 | ||||

22 | 47.9 | 60.1 | 6.08 | 19.6 | 44 | ||||

25 | 47.9 | 62 | 7.06 | 23.4 | 46 | ||||

DN65 | 2 1/2 | 5.5 | 62.4 | 65.9 | 2 7/8 | 1.78 | 11.6 | 48 | 9.14 |

7 | 62.4 | 67 | 2.29 | 13.7 | 48 | ||||

8.5 | 62.4 | 68 | 2.8 | 14 | 50 | ||||

10 | 62.4 | 69 | 3.33 | 14.3 | 50 | ||||

12 | 56.5 | 63.8 | 3.66 | 17.9 | 50 | ||||

14 | 56.5 | 65.1 | 4.32 | 18.2 | 50 | ||||

16 | 56.5 | 66.5 | 5.01 | 20.9 | 52 | ||||

18 | 56.5 | 67.9 | 5.7 | 24.3 | 52 | ||||

20 | 56.5 | 69.3 | 6.42 | 27.1 | 54 | ||||

22 | 56.5 | 70.8 | 7.17 | 29.5 | 54 | ||||

25T&C | 56.5 | 73.1 | 8.32 | 33 | 56 | 8.9 | |||

DN80 | 3 | 3.5 | 75.9 | 79.4 | 3 1/2 | 1.78 | 14.1 | 60 | 9.14 |

5.5 | 75.9 | 80.2 | 2.17 | 14.7 | 60 | ||||

7 | 75.9 | 81.4 | 2.79 | 16.9 | 60 | ||||

8.5 | 75.9 | 82.7 | 3.41 | 19.8 | 60 | ||||

10 | 69.3 | 76.7 | 3.7 | 20.7 | 60 | ||||

12 | 69.3 | 78.3 | 4.49 | 23.5 | 62 | ||||

14 | 69.3 | 79.9 | 5.3 | 26.1 | 62 | ||||

16 | 69.3 | 81.6 | 6.14 | 28.5 | 62 | ||||

18 | 69.3 | 83.3 | 7 | 31.5 | 64 | ||||

20 | 69.3 | 85.1 | 7.88 | 34 | 64 | ||||

22 | 69.3 | 86.9 | 8.79 | 39.9 | 64 | ||||

25T&C | 69.3 | 89.7 | 10.21 | 45.9 | 66 | 8.9 | |||

DN100 | 4 | 3.5 | 100.9 | 104.5 | 4 1/2 | 1.82 | 21.3 | 74 | 9.14 |

5.5 | 100.9 | 106.7 | 2.89 | 24.7 | 74 | ||||

7 | 100.9 | 108.3 | 3.7 | 28.7 | 74 | ||||

8.5 | 100.9 | 110 | 4.54 | 32.7 | 74 | ||||

10 | 100.9 | 111.7 | 5.38 | 36.7 | 74 | ||||

12 | 85.1 | 96.1 | 5.51 | 38.4 | 76 | ||||

14 | 85.1 | 98.1 | 6.51 | 42.3 | 76 | ||||

16 | 85.1 | 100.2 | 7.54 | 46 | 76 | ||||

18T&C | 85.1 | 102.3 | 8.59 | 55.9 | 76 | 8.8 | |||

20T&C | 85.1 | 104.5 | 9.68 | 65.2 | 76 | ||||

22T&C | 85.1 | 106.7 | 10.79 | 71.2 | 80 | ||||

DN150 | 6 | 3.5 | 159.5 | 165.2 | 7 | 2.87 | 45.6 | 110 | 9.14 |

5.5 | 159.5 | 168.6 | 4.56 | 51.5 | 110 | ||||

7 | 159.5 | 171.2 | 5.86 | 63 | 110 | ||||

8.5 | 159.5 | 173.8 | 7.17 | 73.3 | 112 | ||||

10 | 137.9 | 152.6 | 7.36 | 81.2 | 112 | ||||

12T&C | 137.9 | 155.8 | 8.94 | 96.4 | 112 | 8.8 | |||

14T&C | 137.9 | 159 | 10.55 | 114.7 | 112 | ||||

16T&C | 137.9 | 162.3 | 12.22 | 124.7 | 116 | ||||

DN200 | 8 | 3.5 | 193.8 | 200.8 | 8 5/8 | 3.49 | 77.3 | 130 | 8.6 |

5.5 | 193.8 | 204.9 | 5.54 | 90.7 | 130 | ||||

7 | 193.8 | 208 | 7.11 | 104.7 | 130 | ||||

8.5 | 193.8 | 211.2 | 8.71 | 127.4 | 135 | ||||

10T&C | 193.8 | 214.5 | 9 5/8 | 10.34 | 173.5 | 135 | 8.2 | ||

12T&C | 193.8 | 218.9 | 12.56 | 184.6 | 140 | ||||

14T&C | 193.8 | 223.5 | 14.83 | 198.5 | 140 | ||||

FAQ:

1, Connection of the GRE Pipes:

API screw thread seal with aquaseal connection of 8 round or 10 round;

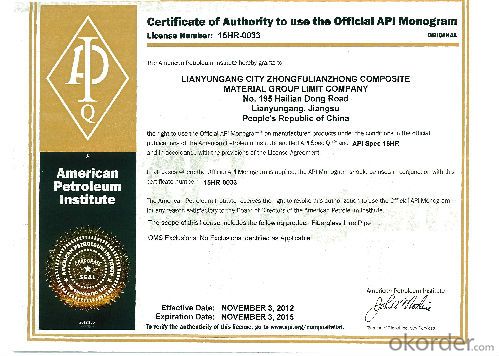

2, Standard of the GRE Pipes?

API Spec 15HR

3, Fittings supplied?

All of the standard GRE fittings are matched well with the original pipes. Most of the fittings are produced by filament winding process.all fittings should be ordered as per thread specification and design pressure.

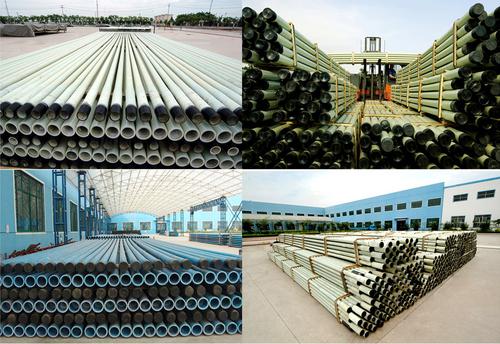

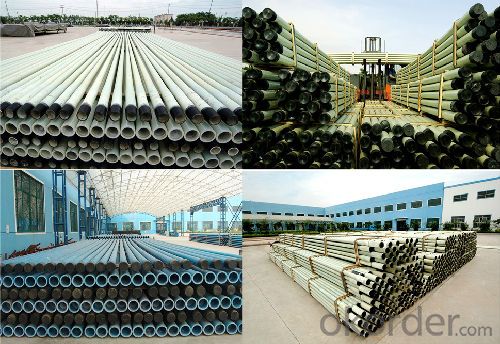

Photos:

- Q: FRP pipe price

- Glass fiber reinforced plastic pipeline is a kind of light, high strength and corrosion resistant nonmetal pipe. It is a resin based glass fiber weight layer wound on the mandrel rotating on according to process requirements, and distance evenly between the fibers as Kamiishi Eisa in the sand layer. The pipe wall structure reasonable and advanced, can give full play to the role of material, to meet the premise of use strength, improve the rigidity, ensure the stability and reliability of the product. Gfrpmp for its excellent chemical corrosion resistance, high strength and light weight, no scaling, strong shock resistance, and ordinary steel compared with long service life, low cost, quick installation, safe and reliable, accepted by the majority of users.

- Q: Is the installation of FRP pipes required qualification?

- However, some industries may have corresponding requirements, and some owners may also require it. For example, apply fiberglass pipes to shipyards

- Q: Characteristics of FRP pipes

- The main pipe forming process of FRP is controlled by a computer for agricultural irrigation, as specified on the mandrel and tube glass fiber winding process the same manufacturing gel lining, according to design good linear and winding structure layer thickness, and the quartz sand and resin sand slurry mixed entangled in the structure layer. The outer protective layer. Raw and auxiliary materials: resin, short cut fiber, continuous glass fiber and quartz sand.

- Q: Is it useful to make gas pipelines with glass steel pipes? Or the idea that the technology is mature?

- Now the general use of steel pipe with PE pipe is very good, I don't FRP clearance, but there may be enamel can also withstand the pressure vessel, 3 class.

- Q: Mending method for glass fiber reinforced plastic pipe

- The method for mending and mending the glass fiber reinforced plastic pipe is hand paste, and the repairing steps are as follows:The stones must be taken away so that the pipes are restored to their original shape.Into the pipe, grinding first and lining the lining. If you can't get into the pipe, polish it from the outside, polish it to the lining, and then make a new lining.Reinforce the structure with a cloth.

- Q: CGCT what's the meaning of the GRP sand pipe?

- The pipeline in the design according to the use of pressure, stiffness and other conditions to determine the need for sand, if the thickness of the pipe can satisfy the pressure requirements and can meet the requirement of stiffness, is generally not the sand.

- Q: What is fiberglass communication tube?

- Fiberglass communication tubes are different from electric protective tubes. Glass fiber reinforced plastic communication tube is a composite structure, the inner layer of glass fiber burr cleaning, and brushing a thicker layer of resin, or lined with a layer of PVC.

- Q: How many times can the temperature withstand of FRP winding pipes? What are the factors?!

- To see what kind of model and materials, the general performance of FRP and cast iron pipe performance close to the temperature range of 100----420 degrees. Affected by the media, the environment is more. Good luck。

- Q: How to improve the compressive strength of waste glass fiber reinforced plastic profiles (such as square tubes) should be started with resin, curing agent, glass fiber or other aspects!

- Use a high strength resin type;

- Q: A basic overview of FRP pipes

- FRP pipes are made of resin (feed water, food grade resin), glass fiber and quartz sand as raw materials and made by special process.

Send your message to us

GRE Pipe for Oil Exploration and Transportation

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 Meters m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords