Gorilla Packaging Tape for PVC Electrical Tape for Electric Wires and Cables

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of PVC Electrical Tape for Electric Wires and Cables

A thin premium grade plasticized PVC film coated with an aggressive rubber based adhesive with good characteristics. It is highly conformable and unaffected by most chemicals and moisture

Application of PVC Electrical Tape for Electric Wires and Cables

Electric insulation below 600V; Insulating wrapping of electric wires and cables; Marking of electric wires and cables; Can be used indoors and out door

Available Size of PVC Electrical Tape for Electric Wires and Cables

Paper Core ID: 76mm; 56mm; 38mm; 32mm

Jumbo Roll size: 1250mm x 33m

Cut roll size: 19mm x 10m; 19mm x 20m or as per customer's requirement

Cut rolls: Nine rolls in one plastic bag, placed in cartons, with or without pallet

Packing of PVC Electrical Tape for Electric Wires and Cables

Jumbo rolls & log rolls: Packed with kraft paper and stretch wrap film, with or without pallet

Cut rolls: Shrink package, placed in cartons, with or without pallet

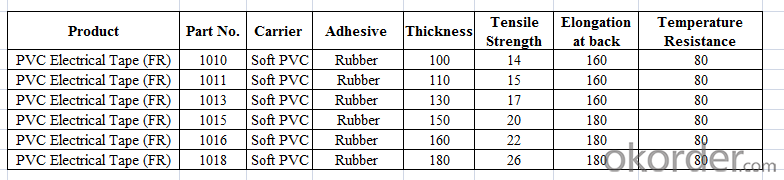

Technical Data of PVC Electrical Tape for Electric Wires and Cables

Product Show of PVC Electrical Tape for Electric Wires and Cables

FAQ: What are your company advantages?

Company Advantages:

1. Stable financial status and sound reputation as a state invested corporation under the direct administration of the State Council of PRC;

2. CNBM’s worldwide influence as one of the 500 global fortunes specializing in building materials including adhesive tapes;

3. More than a decade’s exporting experience and technology in adhesive tape industry;

4. Preferential shipping channels, with a separate team dealing with shipping.

- Q: Can packaging tape be used for sealing musical instruments or equipment?

- Musical instruments or equipment should not be sealed with packaging tape. Although packaging tape is intended for securely sealing boxes and packages, it is not appropriate for sealing musical instruments or equipment for a variety of reasons. Firstly, the use of packaging tape may result in residue or adhesive marks on the surface of the instrument or equipment, potentially causing damage to the finish or overall appearance. Musical instruments and equipment often possess delicate finishes that necessitate special care and attention, and the application of packaging tape could lead to unwanted marks or harm. Secondly, packaging tape may not provide adequate protection or support for fragile or valuable musical instruments or equipment. Musical instruments, particularly those crafted from wood, can be sensitive to fluctuations in temperature, humidity, and pressure. The utilization of packaging tape may not offer the requisite protection to prevent harm during transportation or storage. Instead, it is preferable to employ specialized instrument or equipment cases, covers, or bags that are specifically designed to provide proper protection and support. These cases are purposefully crafted to accommodate the shape, size, and fragility of musical instruments or equipment, ensuring their safety during transportation or storage. If you require sealing a case or cover for musical instruments or equipment, it is advisable to utilize suitable sealing methods as recommended by the manufacturer. This may involve zipper closures, Velcro straps, buckles, or other mechanisms specifically devised for securing musical instruments or equipment. In conclusion, although packaging tape can be valuable for sealing boxes and packages, it is not appropriate for sealing musical instruments or equipment. To guarantee the safety and protection of your musical instruments or equipment, it is best to employ specialized cases or covers designed for this purpose.

- Q: Does packaging tape come in different thicknesses for added durability?

- Yes, packaging tape does come in different thicknesses for added durability. Thicker tapes are often preferred for heavier or more secure packaging needs, as they provide increased strength and resistance to tearing or breaking.

- Q: How does packaging tape perform on oily or greasy surfaces?

- Packaging tape typically does not adhere well to oily or greasy surfaces. The presence of oil or grease can prevent the tape from sticking securely, resulting in poor adhesion and potential for the package to become loose or open during transit. It is recommended to clean and dry the surface before applying packaging tape for the best results.

- Q: Can packaging tape be used for bundling items together?

- Absolutely, packaging tape is perfect for bundling various items together. It serves as a reliable means to firmly secure and hold multiple objects, particularly when engaged in shipping or relocating. Engineered to possess strength and dependability, packaging tape ensures a steadfast grip that effectively keeps items tightly bundled. Frequently employed for the purpose of bundling boxes, packages, or any other items necessitating cohesion during transportation or storage.

- Q: Can packaging tape be used for sealing metal containers or boxes?

- Yes, packaging tape can be used for sealing metal containers or boxes. Packaging tape is typically made with a strong adhesive that adheres well to various surfaces, including metal. It provides a secure and reliable seal, keeping the contents of the metal container or box protected and preventing any unwanted opening or damage during transportation or storage. However, it is important to ensure that the surface of the metal container or box is clean and free from any grease or dirt for optimal adhesion. Additionally, if the metal container or box is exposed to extreme temperatures or harsh conditions, it may be advisable to use a tape specifically designed for those environments to ensure a more durable seal.

- Q: Can packaging tape be used for sealing ceramic items?

- Yes, packaging tape can be used for sealing ceramic items. It can provide a temporary seal and hold the pieces together, but it may not be as effective or long-lasting as specialized ceramic adhesives or sealants.

- Q: Can packaging tape be used for sealing camping or outdoor gear?

- Yes, packaging tape can be used for sealing camping or outdoor gear. It is strong and durable, providing a temporary seal for items such as tents, sleeping bags, and backpacks. However, for longer-term or more permanent seals, it is recommended to use specialized outdoor repair tapes or adhesives designed for outdoor gear.

- Q: Can packaging tape be used on different materials?

- Indeed, various materials can be affixed with packaging tape. Packaging tape exhibits versatility as it can adhere to a broad spectrum of surfaces, encompassing cardboard, plastic, metal, glass, and even fabric. Its primary purpose is to yield a robust and steadfast seal, guaranteeing the preservation of packages throughout their journey and storage. Whether one aims to seal a cardboard box, consolidate multiple items, or fasten a package, packaging tape proves to be an efficacious option for an array of materials.

- Q: Are there any specific instructions for reusing packaging tape?

- There exist specific instructions for reusing packaging tape. Here are several guidelines to adhere to: 1. Exercise caution when removing the tape from the package: Upon receiving a package, make an effort to delicately remove the tape in order to prevent tearing or damaging it. 2. Cleanse the tape: Should the tape possess any dirt, dust, or residue, it can be cleansed by gently wiping it with a moist cloth. Allow it to fully dry before reutilizing. 3. Assess the adhesive strength: Before reusing the tape, verify if the adhesive remains sufficiently strong to securely hold. If it has lost its stickiness or sustained damage, it is advisable to discard it and employ a fresh piece of tape. 4. Properly store the tape: To maintain the tape's quality for future use, store it in a cool, dry area away from direct sunlight. This will assist in preventing it from drying out or becoming brittle. 5. Utilize it for light to medium-duty tasks: Reused packaging tape may not possess the same strength as new tape, therefore it is most suitable for lighter to moderately demanding tasks. Avoid utilizing it for heavy items or applications necessitating a stronger adhesive. Bear in mind, while reusing packaging tape constitutes an excellent approach to waste reduction, it is crucial to prioritize functionality and security. If the tape becomes damaged or loses its adhesive strength, it is advisable to replace it with a new piece to ensure proper sealing of your package.

- Q: Does packaging tape come in different dispenser designs for ergonomic use?

- Yes, packaging tape does come in different dispenser designs that are specifically created for ergonomic use. These designs focus on providing a comfortable grip and reducing strain on the hand and wrist during tape application.

Send your message to us

Gorilla Packaging Tape for PVC Electrical Tape for Electric Wires and Cables

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches