Good Price Wood Plastic Composite Decks from Chinese Factory

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

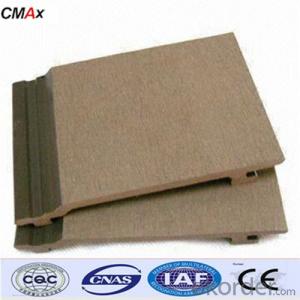

Structure of Good Price Wood Plastic Composite Decks

| Company introduction: | As a professional manufacurer of composite wood plastic decking, we are specialized in producing& promoting environmental friendly composite wood plastic outdoor decking for years. Our sales network covers all over the world, and we've been proved as a trusted supplier to all our customers. For all the buyers who choose our products, you have our guarantee on both quality& service. |

| Material: | 60% bamboo/wood powder 30%HDPE |

| Features: | 1. Waterproof& fire resistant; 2. anti UV/ Fungus/ Insect/ Slip. 3. Tested mechnical performance 4. True-to-nature wood appearance 5. Recyled, easy installation& low maintance,long lasting life span. |

| Available finish: |

Brushed (Smooth), sanded or grained

|

| Colors Available: |

White,Black, Brown, Gray& Teak or customized

|

| Applications: | Home& Garden, Lawn, Balcony, Corridor, Garage, Pool & SPA Surrounds, Boardwalk, Playground and so on. |

| Certificates: |

CE&ISO&SGS

|

| Size: | 150*25 mm |

| Finish: | grooved&sanded&grained |

Main Features of Good Price Wood Plastic Composite Decks

1. Eco-friendly, fully recyclable.

2. With natural wood grain, color and texture, looks like nature wood.

3. Waterproofing, fireproofing, Mildew-resistant, anti-UV.

4. Less cracking, less warping.

5. No need painting, no glue.

6. Can be planed, nailed, drilled and cut to any wanted size.

7. Weather resistant, suitable from -40 to 60°C.

8. Easy to install, clean.

9. Low maintenance, durable, economic, long lifetime

10. Anti-slip, less cracking, less warping.

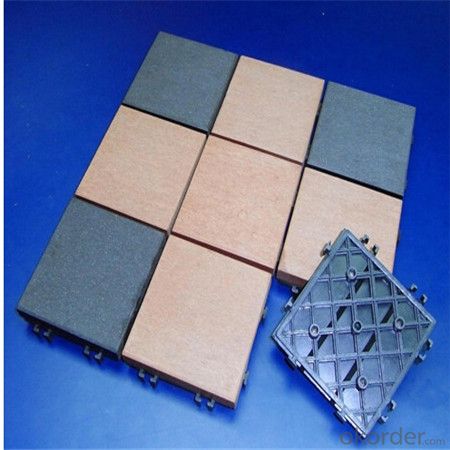

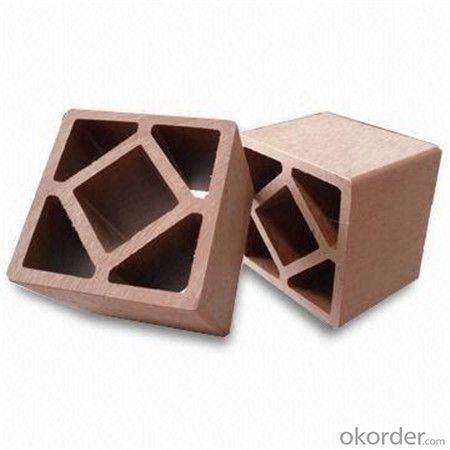

Picture show of Good Price Wood Plastic Composite Decks

Specification of Good Price Wood Plastic Composite Decks

Name | Good Price Wood Plastic Composite Decks |

Size | W*H=145*30 mm, can be customized |

Length | 2200mm, 2800mm, 4000mm, Customized |

Material | Wood Powder, HDPE, Additives |

Surface Finishing | Sanding, Brushing, Wood grain |

Certification | CE, Reach, Intertek, SGS, ISO, FSC |

Range of Application | Outdoor Flooring, Garden, Balcony, Terrace, Pool Surrounds, Boardwalk, Playground… |

FAQ of Good Price Wood Plastic Composite Decks

. What kinds of wpc products do you have?

We have wpc decking in different size, fence series (only wpc material or connect with aluminum profiles, decking tile series.

. Is it difficult to install the wpc board?

No, it is easy to install. Using the tool which you use to install the real wood. Fix the board on the substructure with clips.

. Can you stick the label with our logo on the boards?

Yes, please provide the label drawing, we can stick the customized label on the board.

. What documents are available?

A full range documents, including products pictures, installation guide and relative certificates can be provided; Further more, customs declaration is provided. This is an one-stop service for you.

- Q: My landlord in the balcony painted a thick paint, more than two months later, the smell is still very large, in order to health, and the landlord to negotiate, they agreed to remove the paint layer, but to keep the corner part. Now two days to remove the paint layer, but the smell is bigger. Now I want to purchase the floor, then at the boundary with plastic tape sticking. Do not know whether it can isolate formaldehyde, etc....

- No, because the formaldehyde volatilization is slightly less than the density of gas, air, volatile gas, have good air tightness of floor leather or plastic material, the gas will be volatile and will be hampered by spreading to other direction can be volatile, after all, floor leather and plastic is not closed, on the floor on the floor or other plastic material will have a certain gap, but the floor leather and plastic can be obviously reduced formaldehyde volatilization.

- Q: Wood floor moistureproof can use plastic film?

- Moisture proof performance is the most important technical index. Moisture proof performance of the floor, in the geothermal long time, steaming, once there is moisture into

- Q: What is a plastic floor?

- The plastic floor is very popular in the world today a new light ground decoration materials, also known as the "light body material" in Europe and Asia, Japan and South Korea are popular, popular abroad, from the beginning of 80s to enter the China market, it has been widely accepted in the domestic large and medium-sized city

- Q: How to tear off the plastic film on the floor tiles

- To be transferred to the factory, in order to prevent damage to the floor during the renovation, in the brick surface have done a deal with the pollution, the general polishing brick made of anti fouling wax

- Q: You master the family, to help me, I do not care about the color of plastic bags on the floor tiles, and how to rub are not wiped out, please help me master, I will add the score

- 1, ceramic tiles can be used daily cleaning detergent, soap and other cleaning.2, with a small amount of soap and water mixed with turpentine oil, cleaning tiles can make the tiles more luster.

- Q: What is the name of the plastic floor on the supermarket, where is it?

- Hello landlord! Select the plastic floor must choose the site dedicated, the wrong choice of use and material life, you know! There are many types of plastic floor, mainly divided into coil and sheet, is the most common material, plastic sheet flooring series of thousands of species, like the current popular commercial floor: PVC floor (such as shopping mall (supermarket), hotel, hotel, hospital, school, kindergarten, family, office, commercial airport... Site

- Q: What is the material of the plastic foam plate

- PVC soft material floor soft PVC roll floor general use calendering production. Among them, the filler is less and the plasticizer is more than PVC

- Q: Home decoration with plastic floor, please? What are its strengths and weaknesses?

- To prevent accidental injury; skid resistant, not affected by temperature, wet deformation, reducing the noise comfortable and 5 color pattern is rich, personalized to meet the actual demand of fire; 6

- Q: What is the price per square metre of plastic floor?

- Plastic floor price gap is small, good quality plastic floor price: 45 yuan -80 yuan between. Plus plastic floor accessories and some labor costs in the price: 100 yuan -120 yuan between

- Q: The family is decorated with the plastic corrugated pipe buried in the floor tiles under the good?

- Every one in the family of 2-3 2.5mm root canal - wire is up to 3 4mm - 20, PVC tube enough protection layer plus 15mm, also tick the 40mm deep. This is the norm

Send your message to us

Good Price Wood Plastic Composite Decks from Chinese Factory

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords