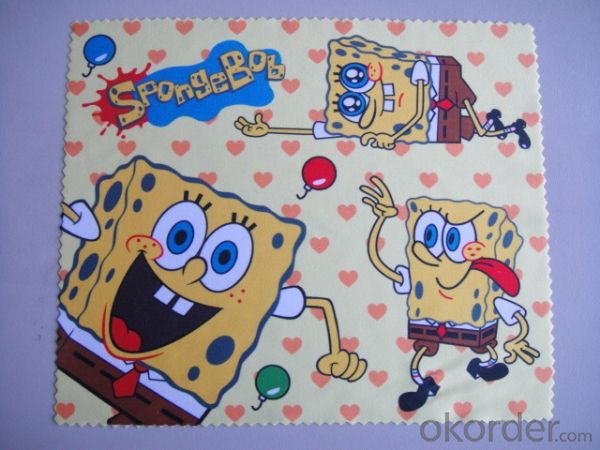

Glasses cleaning cloth with custom logo design

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 5000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of glasses cleaning colth

1.glasses cleaning cloth,microfiber glasses cleaning

2.any size /color is available

3.customized logo

4.polyester&polymide

We manufacture all kinds of microfiber to cleaning cloth,eyeglasses pouch ,polishing cloth ,jewellery bag and so on.

We can customize any product according to your requirements, any size, color, package, qualities, printing is available.

Specialized and experienced, we have engaged in making microfiber products for over 10 years.

Over 5 quality inspectors each department, we have great control on quality aiming at offering you the best goods.

Material 80%polyester+20polyamide / 100%polyester

Size 5*3,5*7,6*8,8*10etc (any size is available)

Printing Digital print, silk print, etc (can print customer logo with Pantone colour)

Colour White, black, orange, yellow, grey, blue, green. Etc (can dye cloth with Pantone colour)

Edge Saw edge, round edge, straight edge, cut cloth into egg shape, etc

Gram weight:(gms)t 180-230gsm

Package 1. 100 pcs each in a polybag 2. each in a polybag 3. individual pvc(vinyl) pouch

MOQ 3,000 pcs (available colors in stock), 20,000 pcs (customized color)

Imprint Silkscreen,digital printing(heat tranfer ptinting),hot stamp,embroidery

Packing

1.bulk packing:100pcs per opp bag 2. individual packing: each in a opp/vinlye bag

- Q: What fabric is made of viscose fiber?

- However, the name of the fabric is not entirely related to the raw material used, but also to the fabric's organizational structure. Such as plain, twill and satin is the basic organizational structure. Now more clothing is the name of the commodity, called a foreign name, in fact, with no relation to cloth structure, raw material, in order to worship.

- Q: Is polyester fiber fabric good for home textiles?

- 80s is the popular Dacron blended polyester fabric. Not afraid of disadvantage, Mars, air permeability, water will become transparent, fabric friction parts will be the light, poor thermal performance etc..

- Q: What are the uses of nanofiber filaments?

- Nano functional finishing technology, mainly refers to the nanometer raw material into forming a protective layer of fabric fiber, unique physical and chemical properties by nanotechnology, increase and improve fabric waterproof, anti oil, anti fouling, breathable, antibacterial, environmental protection, easy to change color, feel comfortable and other aspects of the features, and improve the textile fabric wearing performance, gives the fabric antibacterial health, UV shielding, anti oil and other new characteristics of easy care.

- Q: What is a new type of recycled fiber?

- Tencel fiber is mainly coniferous wood pulp, water and solvent mixed amine oxide, heating to dissolve completely, any derivatives and chemical effects will not occur in the dissolution process, the impurity and direct spinning, its molecular structure is simple carbohydrates. Tencel fiber can be completely decomposed in the soil, no pollution to the environment; in addition, used in the production of amine oxide solvent completely harmless to the human body, almost all of the recovery, can be used repeatedly, in the production of raw materials of pulp cellulose molecules contained no chemical change, no by-products, no waste discharged outside the factory, can be called for the environmental or green fiber. The fabric has excellent moisture absorption, comfort, drape and stiffness and good dyeing, and can be blended with cotton, wool, linen, acrylic, polyester etc., can ring spinning, air spinning, core spun spinning, spinning into various cotton core spun yarn and Mao Xingsha, etc..

- Q: What are polyester fibers and washing methods?

- 1., should be washed with cold water or warm water, do not force to screw;2. times dry shade, not exposure, so as not to rimpled;3., ironing should be put on a damp cloth, the temperature can not be too high, dark clothing, underwear best ironing the reverse side.

- Q: What is the difference between high strength fiberboard and MDF?

- According to their different densities, divided into high density board, MDF, low density board; low density board density is less than 450 kg / m3, MDF density of 450 kg -600 kg / m3, high density board density of 600 kg ~900 kg / m3, it can be seen that the difference in density board and high density board the main is the density, of course, will lead to price differences in different density.

- Q: What's the difference between a gold tube and a carbon fiber?

- Carbon fiber is a new kind of fiber material with high strength and high modulus fiber with carbon content of more than 95%. It is a flaky graphite, microcrystalline and other organic fibers stacked along the axial direction of the fiber, obtained by carbonization and graphitization of microcrystalline graphite material. Carbon fiber "an hand in a velvet glove lighter than aluminum," the quality, but the strength is higher than that of steel, and has the characteristics of corrosion resistance, high modulus, in the national defense and civilian areas are important materials. It has not only the intrinsic characteristics of carbon materials, but also the softness and processability of textile fibers. It is a new generation of reinforced fiber.Carbon fiber has many excellent properties, carbon fiber axial strength and high modulus, low density, high performance, no creep, non oxidation under the environment of high temperature resistance, good fatigue resistance, between heat and electrical conductivity between the metal and non metal, smaller thermal expansion coefficient and anisotropy, good corrosion resistance, X Radiability good. Good conductivity, thermal conductivity, good electromagnetic shielding, etc..

- Q: I asked about the gum. What are the ingredients and what are the characteristics?,

- Viscose fiber is the basic composition of cellulose (C6H10O5) n o, ordinary viscose fiber cross-section of the sawtooth shape, leather core structure, vertical straight, there is groove across. The fiber rich leather core structure, the cross-section is round.

- Q: What is the environmental protection rating of MDF?

- The density board has smooth surface, fine material, stable performance, firm edge and good decoration on the surface of the board. But the density board is poor in moisture resistance, and compared with the density board, the nail holding capacity is worse than that of particleboard. If the screw is tightened, it will be difficult to fix because of the low strength of the density board.

- Q: What's the difference between high density fiberboard, oak and fir?

- Are oak and fir trees pure solid wood? Or MDF, wood, oak, fir? Or MDF, PVC, oak and cedar? The price difference between the three is great.MDF is man-made board. Is a number of wood debris, in accordance with a certain proportion of glue, through some process of repression, and there is a green index, divided into E0, E1, E2 three levels. Strength, hardness, you can rest assured, if you ventilation indoor, moldy, do not worry.Oak, pine, fir wood is relatively scarce, in general, if the oak is solid, then it is oak finger board or fir finger board, the cabinet is more environmentally friendly, but also through some process can be used to make the cabinet, so rest assured you will not moldy.

Send your message to us

Glasses cleaning cloth with custom logo design

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 5000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords