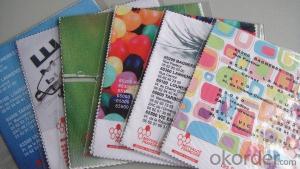

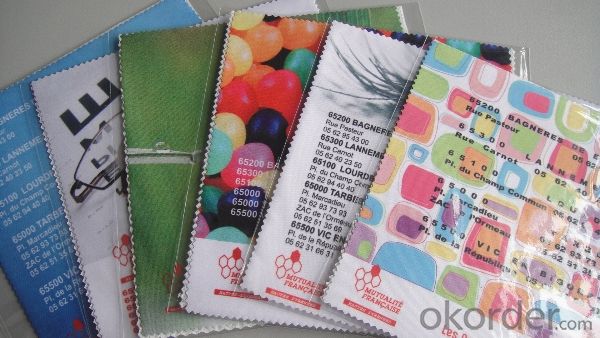

Glasses cleaning cloth with company informations

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 5000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

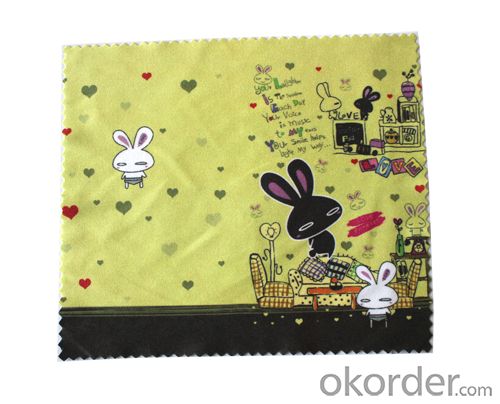

Specifications of glasses cleaning colth

1.glasses cleaning cloth,microfiber glasses cleaning

2.any size /color is available

3.customized logo

4.polyester&polymide

We manufacture all kinds of microfiber to cleaning cloth,eyeglasses pouch ,polishing cloth ,jewellery bag and so on.

We can customize any product according to your requirements, any size, color, package, qualities, printing is available.

Specialized and experienced, we have engaged in making microfiber products for over 10 years.

Over 5 quality inspectors each department, we have great control on quality aiming at offering you the best goods.

Material 80%polyester+20polyamide / 100%polyester

Size 5*3,5*7,6*8,8*10etc (any size is available)

Printing Digital print, silk print, etc (can print customer logo with Pantone colour)

Colour White, black, orange, yellow, grey, blue, green. Etc (can dye cloth with Pantone colour)

Edge Saw edge, round edge, straight edge, cut cloth into egg shape, etc

Gram weight:(gms)t 180-230gsm

Package 1. 100 pcs each in a polybag 2. each in a polybag 3. individual pvc(vinyl) pouch

MOQ 3,000 pcs (available colors in stock), 20,000 pcs (customized color)

Imprint Silkscreen,digital printing(heat tranfer ptinting),hot stamp,embroidery

Packing

1.bulk packing:100pcs per opp bag 2. individual packing: each in a opp/vinlye bag

- Q: What fabric is made of viscose fiber?

- If you follow the classification of fiber components called, of course, viscose cloth.

- Q: What is optical fiber? What's the use of it?

- Optical fibers are made on the basis of this principle. Its basic material is cheap quartz glass, which scientists pull into filaments with a diameter of only a few microns to tens of microns, and then wrap a layer of material with a smaller refractive index. As long as the incident angle satisfies certain conditions, the beam can be twisted from one end to the other in such an optical fiber, without leaking in the middle. Scientists first used this property of optical fibers in optical communications. A light guide fiber can only deliver a very small point of light. If thousands of optical fibers are neatly arranged in a bundle and each optical fiber is in one-to-one correspondence at the ends, it can be made into optical fiber cable. It is incomparable superiority to use optical cable instead of cable communication. For example, the 20 fiber composed of fine fiber like pencils, can call 76 thousand passengers a day, and 1800 copper wires composed like thick cable, every day can only call thousands of passengers. Optical fiber is not only light weight, low cost, easy laying, but also large capacity, anti-interference, stable and reliable, strong confidentiality. The cable is replacing the copper cable, widely used in many fields of communication, television, broadcasting, transportation, military, medical and so on, no wonder people praise for the information age of the nerve fiber. China's own development, production, construction of the world's longest Beijing Han Guang (Beijing, Wuhan, Guangzhou) communication cable, a total length of 3047 kilometers, was opened in October 15, 1993, marking China has entered the era of optical communication applications.

- Q: What's the difference between vinegar fiber and polyester fiber?

- Polyester: 1) polyester fiber is an important variety of synthetic fiber. It is the commodity name of polyester fiber in our country. It is a pure terephthalic acid (PTA) or terephthalic acid methyl ester two (DMT) and ethylene glycol (EG) as a fiber polymer, polyethylene terephthalate as raw materials by esterification or transesterification and polycondensation prepared (PET), the spinning and postprocessing fibers.

- Q: Can the mask made of high electrostatic fiber be washable?

- Some enterprises in order to save costs, require employees to use masks after a period of cleaning two times, there are some mask manufacturers also developed in the middle of the traditional gauze masks sandwiching a layer of meltblown non-woven fabric of the so-called "clean," anti-dust masks are wrong, and dangerous behavior.

- Q: What are the advantages of polyester fabric?

- Lightfastness of polyester fabric is better than acrylic except bad, the light is more powerful than natural fiber fabrics. Especially in the glass behind the light ability is very good, almost be roughly the same with acrylic.

- Q: Is Chiffon polyester?

- Chiffon called "Georgette", also known as Georgette georgette crepe, is a silk fabric with strong twist crepe by crepe weft weaving, georgette name from France (Georgette). Chiffon is classified with silk chiffon and silk chiffon. 1, silk chiffon ingredients are 100% of mulberry silk (natural fiber), 2, artificial silk chiffon general component of 100% polyester, polyester fiber, (chemical fiber).

- Q: What's the difference between polyester fiber and chiffon?

- The two are not coordinate relations, and are subordinate relations. Chiffon is made of polyester and polyester is the raw material of chiffon.

- Q: How do you stick carbon fiber stickers on your car? Also, when there is a large amount of concave, how should I do?

- 1, will need to paste the clean surface in the glass of water please spray in the paste surface ready to paste paper before (after cleaning the body, the body will be in the water with the watering can to put on), is mainly used to reduce viscosity, easy to adjust position sticker;2, determine the need to paste position, together with the car from right to left to or from top to bottom [] lifted aside and wipes the pressing in the car on the table, then, side by side stick cloth pressing, while Jiedi paper;3, meet the door handle or bar according to the material and cut into or set off;4, timely adjustment, the general position of the graphics to determine the correct, with scraper repeatedly scraping water and bubbles, use scraper when from right to left oblique scraping;

- Q: What is the designated outer fiber?

- The fiber especially in heat resistance and chemical resistance than that of spandex fiber, so you can consider developing spandex fiber due to physical reasons and is not involved in the application.The company uses DOW's new polymer based on its original original polymer and combines its own yarn making technology into production. The basic patent belongs to DOW corporation.

- Q: What is the difference between bamboo fiber face towel and ordinary towel?

- Superfine fiber: commonly known as nano fiber. Because of his fine hair fiber is 1/40, if it is a new factory product, feels will have zashou feeling (Note: only illusion Oh, because of his deep pore fiber surface, water absorption) is 3 times that of cotton, suitable for absorbent products and cleaning products, like dry hair cap (CAP), towel, kitchen towel etc.. Pure chemical fiber products are not suitable for making face towels.Pure cotton products: consumer fixed consumption patterns, just like in the year of speculation nylon. Pure cotton has not yet launched the mainstream textile ranks.

Send your message to us

Glasses cleaning cloth with company informations

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 5000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords