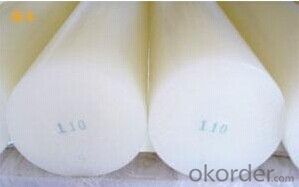

Glass Fiber Textiles Reinforced Zirconia Ceramic Rod

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Zirconia ceramic rods with precision slotted have the advantages of super hardness,high wear-resisting,good corrosion resistance ,high temperature tolerance,, high strength , precision process, high mechanical strength, good chemical stability, polishing surface and so on.

The following data as your reference .

Items | Unit | Data |

Density | g/cm3 | 6 |

Flexural Strength | MPa | 1000 |

Compressive Strength | MPa | 3000 |

Modulus of Elasticity | GPa | 200 |

Impact Resistance | MPa·m1/2 | 8 |

Weibull Modulus | m | 22 |

Vickers Hardness | HV0.5 | 1300 |

Thermal Conductivity | W/mk | <2 |

Highest Application Temperature | °C | 1000 |

Volume Resistivity at 20°C | Ω.cm20 | >1013 |

Dielertric strength | KV/mm | - |

Thermal expansion | X10-6/K | 10 |

Forming methods includes

1,drying pressing

2,isostatic pressing

3,hot pressing casting

The application of our product

1, ceramic shaft for aquatic animals equipment filter pump

2, Ceramic plunger for high pressure cleaner.

3,Wearlessness,resistant acid-base and high intensity ceramic assembly apply to petroleum ,chemical and chemical industry.

4,Wearlesness, corrosion resistance, thermostable parts apply to precision machine.

- Q: Are glass fiber textiles resistant to pilling?

- Yes, glass fiber textiles are resistant to pilling.

- Q: Can glass fiber textile be used in luggage?

- Yes, glass fiber textile can be used in luggage. It is a lightweight, durable, and strong material that can provide added protection to the contents of the luggage.

- Q: How do glass fiber textiles perform in terms of comfort?

- Glass fiber textiles, also known as fiberglass textiles, possess various properties that impact comfort. Firstly, they exhibit high durability and can endure repeated usage and washing without losing their shape or softness. This guarantees that the textiles remain comfortable and do not become rigid or abrasive over time. Moreover, glass fiber textiles possess exceptional moisture-wicking capabilities. They effectively draw moisture away from the skin, ensuring the body remains dry and comfortable. This proves particularly advantageous in hot and humid climates or during physical activities, as it prevents the fabric from becoming damp and clingy. Furthermore, glass fiber textiles exhibit good breathability. They permit the circulation of air through the fabric, aiding in the regulation of body temperature and prevention of overheating. This holds significant importance in situations where the body may perspire, as it helps maintain a cool and comfortable sensation on the skin. In terms of thermal insulation, glass fiber textiles provide moderate warmth. They possess low thermal conductivity, meaning they do not easily transfer heat. This proves advantageous in cool or cold environments, as the textiles assist in retaining body heat and ensuring the wearer remains cozy. However, it is worth noting that glass fiber textiles may be slightly less soft and smooth compared to natural fibers such as cotton or silk. Some individuals, particularly those with sensitive skin or allergies, may find these textiles slightly less comfortable against their skin. In such cases, it is recommended to wear glass fiber textiles with an additional layer of clothing or combine them with other materials to enhance comfort. Overall, glass fiber textiles offer a commendable balance between durability, moisture-wicking, breathability, and thermal insulation. While they may not provide the same luxurious feel as natural fibers, they excel in terms of comfort and are particularly suitable for active or outdoor wear.

- Q: I would like to have a one meter high body sculpture turned into glass fiber reinforced plastic, please ask how thick coated resin, glass fiber cloth should be paved several layers of solid?There is a first mold coating resin coating, or the first in each block die inside coating to be dry and mold, is the first time I turned the glass steel

- In order to make the surface coating can be perfect every time the best coating brush to ensure uniform is best not to paint too good again after curing second timethen brushing to second gel cured thick fiber cloth with ordinary polyester resin paste a layer 0.2 of the fine fiber cloth layer 0.4 to two are not fully the cured blade edge and then repaired with wallpaper on the OK mode

- Q: Can glass fiber textile be used in tennis rackets?

- Tennis rackets can indeed utilize glass fiber textile. Commonly known as fiberglass, this material is frequently employed in the construction of tennis rackets. By weaving glass fibers into a fabric and incorporating it into the racket frame, enhanced strength and stability are achieved. Consequently, the racket becomes more durable and performs better, as it withstands intense gameplay without breaking or bending. Moreover, the utilization of glass fiber textile contributes to the racket's lightweight nature, enabling players to maneuver and swing effortlessly. All in all, due to its advantageous properties and ability to enhance the playing experience, glass fiber textile remains a popular choice for constructing tennis rackets.

- Q: How do glass fiber textiles affect privacy?

- Glass fiber textiles can significantly enhance privacy in various settings. These textiles are made from thin strands of glass, which are woven together to create a strong and durable fabric. Due to their unique composition, glass fiber textiles provide excellent opacity, making it difficult for others to see through them. In residential settings, glass fiber textiles can be used as window coverings or curtains. These textiles effectively block the view from outside, preventing passersby or neighbors from peering into the house. This ensures that individuals inside have a greater sense of privacy, allowing them to go about their daily activities without feeling exposed. Glass fiber textiles are also commonly used in commercial environments, such as offices or conference rooms. By installing these textiles as room dividers or screens, businesses can create private spaces for meetings or personal work. They help to delineate areas and provide a visual barrier, ensuring that confidential conversations or sensitive discussions are not overheard or seen by others. Furthermore, glass fiber textiles can be used in outdoor spaces, such as balconies or patios. When used as privacy screens or enclosures, they allow individuals to enjoy their outdoor areas without worrying about prying eyes. These textiles not only provide privacy but also offer protection from wind, dust, and other external elements. It is worth noting that while glass fiber textiles enhance privacy, they do not completely eliminate visibility. In certain lighting conditions or at close distances, some silhouettes or shadows may still be visible through the fabric. Therefore, it is important to consider the specific needs for privacy and choose the appropriate density and design of glass fiber textiles accordingly. In conclusion, glass fiber textiles play a crucial role in enhancing privacy in various settings. Whether in residential, commercial, or outdoor spaces, these textiles provide effective opacity, preventing unwanted views from outside. They are a versatile and practical solution for individuals and businesses seeking to create private and secure environments.

- Q: Can glass fiber textiles be used in automotive headliners?

- Glass fiber textiles are capable of being utilized in automotive headliners. With their lightweight and high strength, glass fibers prove to be an ideal material for automotive applications. They possess exceptional sound absorption and insulation properties, which play a crucial role in reducing noise and heat transfer in vehicles. Moreover, the versatility of glass fiber textiles enables them to be easily molded into intricate shapes, allowing for customization and the integration of various features such as lighting, air vents, and speakers. Furthermore, their resistance to moisture, chemicals, and UV radiation guarantees the durability and longevity of the headliners. Overall, the numerous advantages offered by glass fiber textiles make them a suitable choice for automotive headliners.

- Q: What are the different surface patterning options for glass fiber textile?

- Glass fiber textiles offer various options for surface patterning. These include: 1. Plain Weave: The simplest and most common type of surface patterning for glass fiber textiles. It involves interlacing fibers in an over-under pattern, resulting in a smooth and uniform surface. 2. Twill Weave: Characterized by a diagonal pattern created by interlacing fibers. This type of surface patterning enhances the strength and flexibility of the glass fiber textile. 3. Satin Weave: Another popular option known for its lustrous and smooth surface. Achieved by floating warp threads over multiple weft threads, satin weave provides flexibility and a luxurious appearance. 4. Jacquard Weave: Allows for intricate and complex designs to be woven into the glass fiber textile. Achieved using a special loom with a Jacquard attachment that controls individual warp threads, resulting in detailed patterns. 5. Embossed or Textured Patterns: Glass fiber textiles can also be patterned through embossing or adding textures. Embossed patterns are created by pressing the fibers onto a heated patterned roller, resulting in raised designs. Textured patterns can be achieved by adding materials like resins or foams, creating a three-dimensional surface. 6. Laser Etching: A modern technique that uses a laser to remove specific areas of the glass fiber textile, creating precise and intricate patterns. This method allows for high customization and detailed designs. Overall, the choice of surface patterning for glass fiber textiles depends on the desired aesthetics, functionality, and performance requirements of the end product. Each option offers unique characteristics and can be tailored to specific needs.

- Q: Can glass fiber textile be recycled?

- Yes, glass fiber textile can be recycled. Glass fibers can be melted down and used to make new glass products or spun into new textile materials. The recycling process involves collecting and sorting the glass fiber textiles, removing any contaminants, and then processing them through a heating and melting process. This melts the glass fibers, allowing them to be formed into new products. Recycling glass fiber textiles helps to conserve resources, reduce waste, and minimize the environmental impact of the textile industry.

- Q: What are the different surface treatments available for glass fiber textiles?

- Glass fiber textiles offer a range of surface treatments, each serving a specific purpose and providing unique advantages. Some of the most commonly used treatments include: 1. Sizing: During the manufacturing process, a protective coating known as sizing is applied to the glass fibers. This coating enhances the textile's handling and processing characteristics, ensuring better control and stability during weaving or knitting. 2. Silane treatment: By applying a silane coupling agent to the glass fibers, the adhesion between the fibers and various resin systems, such as epoxy or polyester, is improved. This treatment enhances the overall strength and durability of the composite material. 3. Coating: Coating involves applying a layer of protective material, such as acrylic, polyurethane, or silicone, to the glass fiber textile. This adds additional properties like water resistance, UV resistance, or flame retardancy. 4. Laminating: A layer of film or fabric is bonded to the surface of the glass fiber textile in the laminating process. This treatment provides extra strength, stiffness, or decorative effects to the textile, as well as improved resistance to chemicals or abrasion. 5. Dyeing or printing: Dyes or pigments can be used to add color or patterns to glass fiber textiles. Dyeing can be done during manufacturing, while printing involves applying color or designs onto the textile's surface. These treatments enhance the textile's aesthetic appeal and visual appeal. In summary, the various surface treatments available for glass fiber textiles aim to enhance their performance, durability, and appearance. The choice of treatment depends on the specific properties and application requirements of the textile in question.

Send your message to us

Glass Fiber Textiles Reinforced Zirconia Ceramic Rod

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches