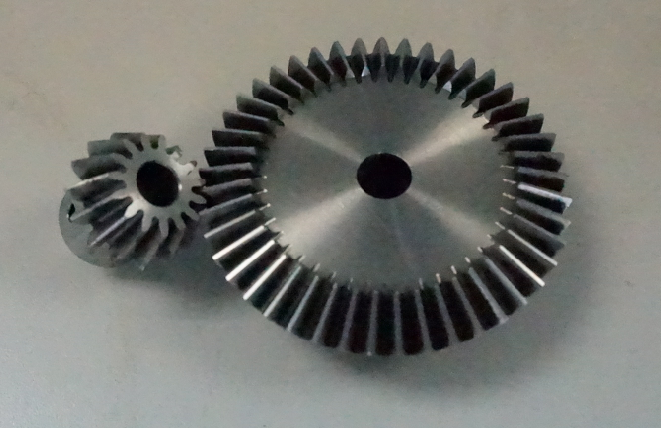

GEARS DIN ANSI Large Steel shaft Gear of China Manufacturer

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | packed in carton |

| Delivery Detail: | 70days |

Specifications

1.produce as drawings

2.material will be as requirements

3.strictly quality control

4.OEM is acceptable

Products information:

1. suitable for many sorts of transmission system, such as agriculture tractor, wind power, truck and other industry zone.

2. material and precision can be as requirements.

3. we have complete gear machining equipments: gear hobbing machine, shaving machine, gear shaper, gear grinding machine, and our own heat treatment center. all of the production procedure are strictly controlled by ourselves, no cooperation procession, so we can sure the final products to meet your requirements.

4.each processing, strictly quality control

5.certificate: ISO9001, ISO/TS16949

- Q: How to prevent the transmission shaft from breaking and falling off?

- Must be maintained regularly in accordance with technical specifications. Make sure the parts are well secured and well lubricated.The strict implementation of the standard maintenance, maintenance in V type with a dial indicator measuring shaft bending, if more than 0.SInmSubject to correction.Lubricate the intermediate bearing periodically, and install the bearing cap properly, adjust it in use.Replace the worn cross axle, bearings and other transmission parts in time.In the use of vehicles, attention should be paid to starting, shifting smoothly, reasonably using clutch and brake to reduce the impact of power transmission.

- Q: Drive to do a linear movement of the spiral, look at the net efficiency of the ball screw rod is relatively high, if the ball screw to make the counter revolution, is the nut with a one-way bearing vertical fixation, screw up and down reciprocating motion, so that you can do, if possible, wire rod length 40CM screw diameter, 8MM, vertical pressure 80N of the screw, choose the lead big nut can make the speed to 700 RPM in the under pressure?

- This usage is really special. I have 3 years to lead screw sales have not encountered.

- Q: What kind of lubricant does nylon transmission use?

- Yes, you are not very high speed. I want to know more about the detailed working conditions there. Do you want to contact me?

- Q: This problem for a long time, a drive shaft with a key, how to fix the position after the rotation of concrete keyway, don't specify the rotation and rotation angle, through parallel or perpendicular to that location

- I've seen other people, can first determine a plane for reference and choose the angle

- Q: The axial force of this drive eliminates the problem of how to do it! Thank you for the exam tomorrow

- It's too much trouble drawing you. Let's give you a train of thought.Bevel gear 1 and 2 drive the axis II to the right direction; in order to offset the force of the axis II, it requires the rotation of the helical gear to meet the gear 4 to gear 3 to the left of the force. (it's about coaxial steering.).

- Q: What are the functions of an automobile powertrain? What is the function of each part of it?

- Rear drive - RR: rear engine, rear wheel driveThis type of arrangement is adopted on large passenger cars, and a small number of mini and light sedans are also adopted. The rear engine, the front axle is not easy to overload, and can make full use of the trunk area, also can effectively reduce the floor height or the middle of the bus to make full use of the space below the floor luggage, but also conducive to reduce the impact of high temperature and noise of engine drivers. The disadvantage is that the engine cooling conditions are poor, some of the faults in driving are not easily detected by the driver. The long distance operation also makes the control mechanism complex and inconvenient for maintenance and adjustment. But because of its outstanding advantages, it is used more and more in large buses.

- Q: When the coupling is linked, can the drive shaft be thinner than the motor shaft?

- Coupling calibration is not required if the motor shaft and the drive shaft misalignment is that your motor installation seat problems both have, because you find it to two concentric since coupling is not so high the

- Q: What part of the transmission mechanism of the walking conveyor?

- Belt driveBelt drive design, should check the wheel size and its related parts size coordination. For example, the outer diameter of the belt pulley that is mounted on the reducer or motor shaft shall be coordinated with the reducer and motor center to avoid collision with the chassis or other parts.

Send your message to us

GEARS DIN ANSI Large Steel shaft Gear of China Manufacturer

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords