Gate Valve of DIN3352 F4 RUBBER on Sales

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 150 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Ball Valve Description:

Threaded ball valve is closed is a ball, ball around the center line of the body as a rotation to achieve a kind of open and close the valve.

Ball valve in the line is mainly used for cutting, distribution, and change the flow direction of medium. Two type ball valve, three type ball valve, is widely used in recent years a new type of valve, the valve average installation. And ball valve is a kind of ball valves, threaded pipe connection is screwed connection, and flanged ball valves, welded ball valve, etc.

2. Main Features of the Ball Valve:

• Small flow resistance;

• Simple structure

• Small volume, light weigh

• Small volume, light weigh

• Easy to operate, open and close quickly, facilitate remote contro

• Easy maintenance, sealing ring, which generally remove easy to change

• Full open or full close, sphere and valve seat sealing surface and the dielectric isolation, medium through does not cause the valve sealing surface erosion.

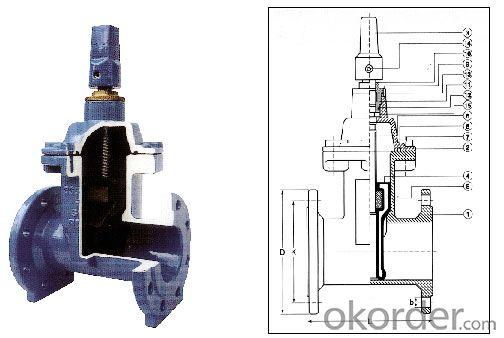

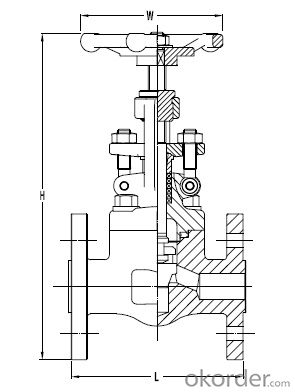

3. Images

4. Ball valve Specification

5.FAQ

1. What's are the characteristics of ball valve?

The distinct feature of a ball valve is the sealing surfaces between the gate and seats are planar, so ball valves are often used when a straight-line flow of fluid and minimum restriction is desired. The ball valve faces can form a wedge shape or they can be parallel.

2. What is the work principle of ball valve ?

The ball valve faces can form a wedge shape or they can be parallel. Ball valves are primarily used to permit or prevent the flow of liquids, but typical ball valves shouldn't be used for regulating flow, unless they are specifically designed for that purpose. Because of their ability to cut through liquids, ball valves are often used in the petroleum industry.

3. What is the structure?

Bonnets provide leakproof closure for the valve body. Ball valves may have a screw-in, union, or bolted bonnet. Screw-in bonnet is the simplest, offering a durable, pressure-tight seal. Union bonnet is suitable for applications requiring frequent inspection and cleaning. It also gives the body added strength. Bolted bonnet is used for larger valves and higher pressure applications.

- Q: What is the soft seal gate valve?

- General soft sealing gate valve model is Z41X Ming bar. The dark pole is Z45X. They're all for hydraulic purposes

- Q: Gate valve, butterfly valve, ball valve advantages and disadvantages? What are the usual valves?

- Steam traps: in steam, compressed air and other media, there will be some condensation water formation, in order to ensure the efficiency and safety of the device operation, should be timely discharge of these useless and harmful to the media, to ensure the consumption and use of the device. It has the following functions: 1. It can quickly eliminate the condensed water; prevent leakage of steam; remove air and other non condensable gases.Pressure reducing valve: by adjusting the inlet pressure to a certain outlet pressure, and rely on the energy of the medium itself, so that the outlet pressure automatically maintain a stable valve.Check valve: also known as reverse flow valve, check valve, back pressure valve and one-way valve. The valves are automatically driven and closed by the flow of the medium itself, belonging to an automatic valve. The check valve is used for piping system, the main function is to prevent the backflow of medium, prevent the reverse of pump and drive motor, and release the container medium. The check valve can also be used to provide a supply to the auxiliary system where the pressure may rise above the system pressure. It can be divided into swing type (rotating by gravity center) and lifting type (moving along the axis).

- Q: Gate valve DN65 what does that mean?

- Nominal diameter 65 gate valve.This depends on the material of your valve, it is new material, it is to use the outer diameter to do the standard, specifications with 63.75, and so on, because the new material is welded or coated with glue connection. So use the outside diameter as the standard, or the gap will appear.There is also the metal standard, according to the nominal diameter, or flange connection flange and skein skein are industry specifications.When it comes to the end, it must be between the pipe and fittings must be connected.

- Q: How about the model of stainless steel gate valve?

- Stainless steel gate valve is divided into 304 stainless steel gate valve, 316 stainless steel gate valve, 321 stainless steel gate valve. The expression is: Z41H-16P.

- Q: Is the gate valve clockwise or closed?

- In general, the valve is clockwise turn off, in the case of special requirements under the opening.

- Q: Function of gate valve

- Valve strengths: (1) fluid resistance is small, due to the valve inside the valve channel is straight, and the medium flow through the valve does not change its direction of movement, so the fluid resistance is small. (2) the opening and closing moment is small, opening and closing more effort, as the gate valve opening and closing, the direction of movement of the gate and the direction of the media movement vertical, compared with the cut-off valve, valve opening and closing more effort. (3) the direction of the movement of the media is not limited, no disturbance, no pressure reduction, the media can flow in any direction from both sides of the gate valve, and all can achieve the purpose of use, more suitable for the direction of the movement of the medium may change in the pipeline. (4) the length of the structure is relatively short, because the gate of the gate valve is vertical inside the valve body, and the stop valve clack is horizontally placed in the valve body, so the length of the valve is shorter than the cut-off valve. (5) the sealing function is good, when the full opening, the sealing surface is less eroded. (6) when fully open, the sealing surface is less eroded by the working medium than the cut-off valve. (7) the shape is relatively simple, the forging technology is good, and the scope of application is wide.

- Q: What is the gate valve for the DN65 hydrant?

- DN150, of course. Ask me about fire protection

- Q: What is the difference between the cut-off valve and the gate valve?

- What is the difference between gate valve and stop valve?:Gate valve and globe valve structure is different, the valve structure for hand wheel, with the stem rotating together to do the opening and closing movement. Valve structure is rotating handwheel, stem do lifting movement. The flow is different, the gate valve requires full open or full closed state, the cut-off valve does not need. The valve has the flow direction requirements, and the gate valve has no inlet and outlet requirements!Sealing performance comparison:Valve length is shorter than the cut-off valve, higher than the cut-off valve, the valve should pay attention to the installation of high elevation. The gate valve can be tightly closed with the sealing surface by the pressure of the medium so as to achieve the effect of not leaking.

- Q: What is plug welding gate valve?

- Plug connection pipeline welding mode safety gate valve

- Q: Fire protection gate valve from the wall how many distance there is no regulation?

- 1 meters away from the wall, leaving the maintenance and replacement distance

Send your message to us

Gate Valve of DIN3352 F4 RUBBER on Sales

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 150 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches