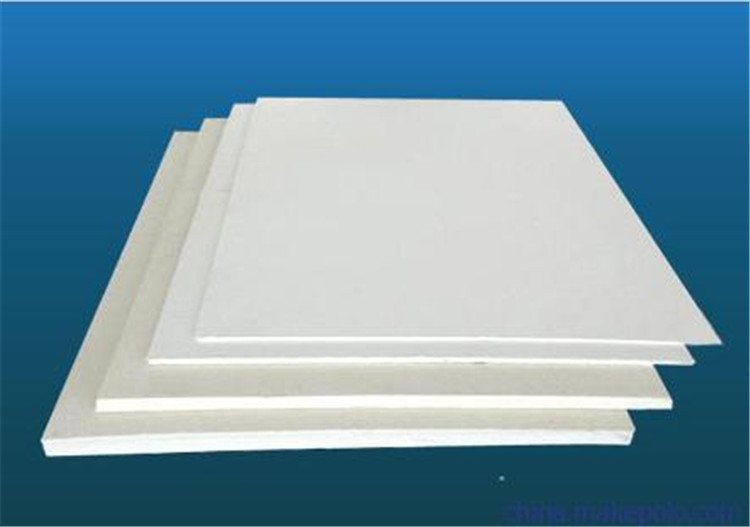

High-Quality Ceramic Fiber Board for Furnace and Kiln Heat Insulation

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Refractory Ceramic Fiber Board

Product Description

General Information

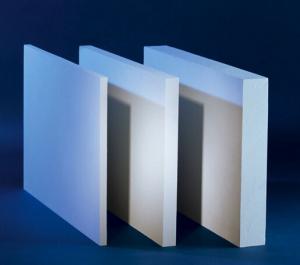

CMAX ceramic fiber boards are manufactured in a wet vacuum forming process by blending the chopped ceramic fiber with inorganic or organic binders for excellent abrasive resistance at high temperature.

The products are classified as STD, HP, HA, and HZ respectively corresponding to different maximum service temperature 1000 centigrade,1100 centigrade,1200℃ centigrade and 1350 centigrade.

Feature

Low thermal conductivity

Excellent thermal shock resistance

Excellent chemical stability

Even density and thickness

Non standard sizes are available upon request

Application

Hot air duct ling

Shuttle kiln with high gas velocity

Laboratory furnace

Kiln car insulation

Die-cut high temperature seal

Technical data of heat insulation board

Grade | Common | Standard | High Pure | High Aluminium | Zirconium | |

Max. Temperature (°C) | 1100 | 1260 | 1260 | 1360 | 1430 | |

Working Temperature (°C) | ≤1000 | 1050 | 1100 | 1200 | 1350 | |

Color | White | Pure White | Pure White | Pure White | Pure White | |

Density (kg/m3) | 220-500 | 220-500 | 220-500 | 220-500 | 220-500 | |

Shrinkage on heating (%)(Temperature 24 hours, density as 320kg/m3) | -4 | -3 | -3 | -3 | -3 | |

Thermal conductivity by mean temp. (W/m.k.) (density 285kg/m3) | 0.085(400°C) | 0.085(400°C) | 0.085(400°C) | 0.085(400°C) | 0.085(400°C) | |

Compression strength (Mpa) | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | |

Chemical Composition | AL2O3 | 44 | 46 | 47-49 | 52-55 | 32-33 |

AL2O3+SIO2 | 96 | 97 | 99 | 99 | - | |

AL2O3+SIO2+ZrO2 | - | - | - | - | 17-18 | |

ZrO2 | - | - | - | - | 15-17 | |

Fe2O3 | <1.2< p=""> | <1.0< p=""> | 0.2 | 0.2 | 0.2 | |

Na2O+K2O | ≤0.5 | ≤0.5 | 0.2 | 0.2 | 0.2 | |

Size(mm) | 600x400x20-50 ; 900x600x20-50 ;1200x1000x20-50 (Other sizes and shapes on request.) | |||||

Package | Carton box | |||||

Certificates | ISO9001-2008, MSDS | |||||

Packaging & Shipping

Packaging & Delivery

Packaging Details: carton,or according to customer's requirement

Delivery Detail: 30 days after order

Cataloge

We offer a wide range of ceramic fiber products, to cater to a range of domestic and commercial applications.

Ceramic Fiber Blanket:STD,HP,HA,HZ

Ceramic Fiber Board:STD,HP,HA,HZ

Ceramic Fiber Paper:STD,HA,HZ

Ceramic Fiber Module:STD,HP,HA,HZ

Ceramic Fiber Textiles:Cloth,Tap,Yarn,Rope,Square Packing,Ladder,etc

Our Services

Optimum solution and product supply of refractories for high temperature industries, such as iron&steel, non-ferrous, petrochemical and building materials.

♥ Engineering design, contract and consult for refractories, and civil architecture design.

♥ Research,development, manufacture and sale of superhard materials.

♥ R&D, manufacture and sale of special packing materials for export.

♥ Inspection,supervision and arbitration of refractories.

♥ Consultation and services in refractories information.

♥ Training and cultivation of high-level talents in refractories profession

Detailed Images

- Q: What method should be used to measure the thermal conductivity of fiberboard?

- Fiber board thermal conductivity of ceramic fiber board thermal conductivity information is mainly: ceramic fiber board thermal conductivity, thermal conductivity of ceramic fiber board price, thermal conductivity of ceramic fiber board wholesale, thermal conductivity of ceramic fiber board factory, discusses the protection method of hot plate test principle and method of MDF thermal conductivity and its relation with temperature; and analyzed the test error.

- Q: What are the standards for ceramic fiber boards?

- The existing ceramic fiber board has broken through the age of fear of water, and the newly developed hydrophobic ceramic fiber board has the characteristics of normal working under the water environment.

- Q: Ceramic fiber plate and aluminium silicate plate are chosen as lining materials

- Ceramic fiber board is of high quality ceramic fiber cotton with low slag ball content as raw material, using specific pulp and mixing equipment, ensure the cutting length and the concentration uniformity of cotton fiber, using international advanced vacuum molding technology and international advanced processing technology, the product not only has excellent mechanical strength and precise geometry the size, and maintains the excellent properties of fibrous insulation materials, can be substituted for calcium silicate board also requires tough, self-supporting and refractory insulation field.

- Q: Refractory insulation board, pressure plate, nano heat transfer plate, calcium silicate board and ceramic fiber board, which is good?

- Sheng Yang series of ceramic fiber board is based on the traditional process of comprehensive upgrading of the excellent vacuum forming insulation materials, slag ball content of less than 3%, fiber distribution uniformity, internal and external strength consistent, size controllable.Ceramic fiber board is made by spraying superfine ceramic fiber through water washing, slag removal, fiber freezing and vacuum forming. The product has superior high temperature resistance, excellent rigidity and toughness.

- Q: What are the sound-absorbing fiber boards?

- Ordinary materials have sound-absorbing effect, just how much difference. And when it comes to sound-absorbing board, we are only sound-absorbing coefficient of more than 0.3 of the material known as sound-absorbing material.

- Q: What is the difference between ceramic fiber board and nano ceramic fiber board?

- The traditional ceramic fiber board has good heat insulation, high temperature resistance to certain characteristics, widely used in kiln products, but this tradition also has some shortages, low intensity, high temperature and high pressure, there are restrictions on the application of kiln stress.

- Q: What are the specifications of the ceramic fiber board?

- Ceramic fiber board common specifications are: 600*400, 900*600, 1000*600 and 1000*1200mm, thickness 10/20/25/30/40/50mm, thinnest can do 6mm.Depending on the temperature range, it can be divided into:Common ceramic fiber board HLGX-164Standard ceramic fiber board HLGX-264High purity ceramic fiber board HLGX-364High alumina ceramic fiber board HLGX-464Ceramic fiber board containing zirconium HLGX-564

- Q: What are the differences between nano ceramic plate and ceramic fiber board?

- Ceramic fiber board is a kind of ceramic fiber cotton produced by injection technology. It is made by continuous production and advanced technological production line.

- Q: What are the uses of ceramic fiber boards?

- The ceramic fiber board, also called aluminum silicate fiber board or refractory fiber board, is divided into five grades according to the temperature grade:Fire dragon type ceramic fiber board HLGX-164Fire dragon standard ceramic fiber board HLGX-264Fire dragon high purity ceramic fiber board HLGX-364The dragon of high alumina ceramic fiber board HLGX-464Fire dragon contains zirconium type ceramic fiber board HLGX-564

- Q: Is there any difference between ceramic silicon fiber board and ceramic fiber board?

- Distinguishing.Ceramic silicon fiber board by long fiber silica, clay, talc, glaze etc. after 1150 degrees high temperature sintering, twenty-first Century revolutionary high-tech building materials. Characteristics: flexibility, high toughness, high strength, anti wind pressure; with homogeneous magnetized light ceramic surface, disposable, pores, anti pollution, is not easy to dust, mildew, antibacterial, deodorant, anti slip, no static, not fear of chemical erosion, such as acid, alkali, or even sulfate; fire, smoke, high temperature resistance, easy processing, cutting a hole.

Send your message to us

High-Quality Ceramic Fiber Board for Furnace and Kiln Heat Insulation

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords