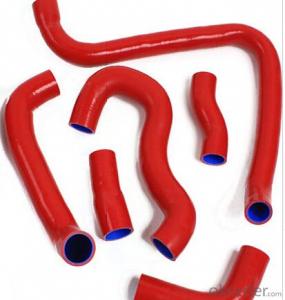

Full Range Silicone Radiator Hose Kit for Car

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 5000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

- Cover: Abrasion and weather resistant synthetic rubber

Color: Black according to customer's request

Size: 3/4 inch

Temperature: -40-100 ℃

Print words: Customized

Business type: Manufacture

Features

High temperature automotive custom silicone hose features:

1) Working temperature: -40 ~ 240 degrees

2) Reinforcement: Polyester or nomex fabric

3) Color: different color can be provided.

4) Size tolerance: +/-0. 5mm

Application

The developed universal products including: Straight Coupler Hose, Reducer Hose, Hump Coupler Hose & Hump Reducer Hose, 45/90/135/180 degree Elbow & Elbow Reducer Hose, 45/90 degree Hump Elbow & Hump Elbow Reducer Hose, T-Piece Hose, U-Shape Hose, Vacuum hose, Fuel resistent hose, Viton silicone hose,etc, all are in various Inner Diameter sizes

Our Service

We can offer OEM Services

We can provide FREE SAMPPLE for our customers

We can crimp hose assembly for our customers.

We welcome clients to visit our factory leading to better understanding of our production

FAQ

Q1. Do you produce smooth or cloth wrapped cover?

A. Both, we can produce both cover, which depends on customer’s request.

Q2. Do you produce embossed marking?

A. Yes, we do provide embossed and printing markings with different color.

Q3. Can you produce product with my own brand?

A. Yes, we have been offering OEM services for 20 years.

Q4. Does your product have different color hose?

A. Yes, we currently provide black, grey, red, blue and yellow.

Q5. How long does my order take to be delivered?

A. It usually takes 5 to 30 days, which generally depends on the quantity of your order and our storage.

- Q: What glue can glue rubber tube?

- 1: clean: high temperature, quick drying glue, use dry cotton cloth or sand paper, then dust, oil, rust, etc., and then use the treatment agent or cleaning agent to clean, then clean the surface.2, sizing: flexibility speedglue unscrew the front cover, can be used as a glue bottle with cotton cloth to wipe clean and quick drying glue, can be set using needles or PE dropper, to control the flow of glue, ensure the bonding effect.

- Q: Is hot melt hose toxic and harmful?

- The heater adopts the U.S. and high temperature heating wire line, uniformly wound around the pipe wall, with thermal insulating properties and uniformity, good heat resistance, heat insulation material of high quality, ensure that the insulation performance of larynx.

- Q: How far is the gas cooker from the gas riser in the kitchen?

- Rubber hose for gas shall use oil resistant rubber hose, length of 1.2-1.5 meters, length not exceeding 2 meters.

- Q: Diameter 127mm steel pipe, and diameter 127mm rubber hose how to connect?

- Connection method:1, send special purchasing rubber pipes, as far as possible to choose the correct tolerance.2, if the work pressure is not more than 0.7MPa, the end of the steel pipe can be in accordance with the rubber tube inside the car, a knife.3, the processing of a casing.

- Q: Classification of metal hoses

- Corrugated metal hose from the structure point of view, metal bellows with two pieces of tape and pipe, they can be molded out of ring bellows and spiral bellows. Just because the corrugated pipe buckle strip forming there is always a certain length of brazing or welding and joints, these places often have accumulated working medium residue, and precipitated a mechanical impurities pollution cavity cleaning test and working medium. As a result, its trustworthiness is relatively poor. Bellows ring is the number of rings and several concave diaphragm outer concentric semi circle tangent, and several inner concave semicircular ring connected with the vest tangent to the special geometry of the pipe. Its billet is mainly made of tubes, and this kind of bellows has the characteristics of large flexibility, good elasticity, simple manufacture and small rigidity. Suitable for making general pressure, flexible requirements of high, medium diameter of the metal hose. Spiral corrugated pipe is a certain length of the spring winding shaped diaphragm spring shape around the outer edge and concave concentric semicircular ring tangent, and inner spring winding shaped concave semicircular ring connected with the vest tangent to the special geometry of the pipe. The corrugated tube has the characteristics of high strength, large rigidity and simple manufacture, and is suitable for making metal hose with high and medium pressure requirements, high and medium pressure, medium and small diameter.

- Q: What about leakage of hose joint?

- No matter what kind of pipe joint leaks, you can repair the hose with a special adhesive tape for temporary repairs. Specific operation method is: first, close the valve after the water is cut off, open the faucet to the appropriate position to release most of pressure inside the pipe and then use special tape tied Water Leakage parts, or with epoxy adhesive to seal.

- Q: Which is safer for stainless steel bellows and rubber tubes for gas pipelines?

- The stainless steel bellows and the quick fitting joint connection way mostly uses the end face seal, may avoid the thread seal to be lax strictly the leakage, compared with the traditional installment, its leakage probability will reduce greatly.

- Q: Acid burette and how to distinguish the basic buret

- Acid burette glass valve cock, the basic buret is latex tube with glass balls

- Q: How can I remove all the flavor on the rubber hose?

- The rubber itself is tasteless, and the smell of the rubber we smell is the flavor of a vulcanizing agent or accelerant.Cover or dry.

- Q: Is the rubber pipe joint installed in the middle of the pipe and pump for shock absorption?

- According to the pumping station environment, the noise source is not close to the pump house for sound insulation treatment, the noise of the pumping room will be taken sound absorption / sound insulation treatment, doors and windows should do sound insulation treatment, and so on.

Send your message to us

Full Range Silicone Radiator Hose Kit for Car

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 5000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords