FRP Pultrusion Profiles - Fiber Glass Reinforce Plastic Pultruded Handle

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 50000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

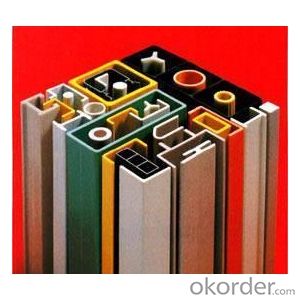

General Description of FIBERGLASS HANDLE:

Fiberglass handle is manufactured byhigh-strength fiberglass as reinforcing material, thermosetting resin as the base, and then taken shape on a special pultruded mold, where the high temperature activates the resin to cure.

Main Features of Pultruded Handle:

1. light weight and high strength

2. anti-ageing

3. aesthetically pleasing appearance

4. environmental friendliness

Main Application of Pultruded Handle:

farming tool: shovel, hoe, pickaxe, ax, hammer etc.

gardening tool: grass shears, tree pruner, fencing shears, grass harrow etc.

cleaning tool: mop, broom, window brush etc.

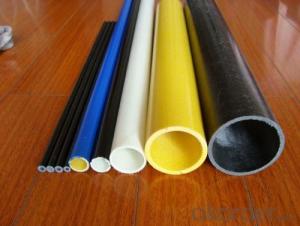

Main Specification of Pultruded Handle:

Normal size | φ32*φ26, φ32*φ27.5, φ32*φ28, φ32*φ22, φ31*φ25,φ30*φ26, φ30*φ24, φ28*φ24, φ28*φ22, φ25.4*φ20.5, φ25.4*φ18.4, φ24*φ20, φ22*φ18.4 |

Surface effect | nexus mat surface, continuous strand mat surface, stitched mat surface, painting surface, wood texture surface |

Regular Color | yellow, red, blue, green, white, gray |

FAQ:

1, Why choose us?

We are stated owned company, more realiable, more safety;

We have international team which can provide professional and correct service as per buyer requirement;

We have fast response and good after-sale service, since we have lot of branch office all around world;

- Q: Are FRP pultrusion profiles resistant to seismic activity?

- Yes, FRP pultrusion profiles are generally resistant to seismic activity. Due to their high strength-to-weight ratio and excellent flexibility, FRP profiles have demonstrated great resilience and durability during seismic events. Additionally, their non-corrosive nature and superior fatigue resistance make them suitable for seismic-prone regions. However, specific design considerations and engineering analysis are necessary to ensure optimal performance in seismic conditions.

- Q: Can FRP pultrusion profiles be used in the construction of pedestrian bridges?

- Pedestrian bridges can utilize FRP pultrusion profiles, which offer numerous advantages for bridge construction. Firstly, these profiles are lightweight yet incredibly strong and durable, making them ideal for weight-sensitive pedestrian bridges. The lightweight nature of FRP profiles also simplifies transportation and installation, resulting in cost savings. Secondly, FRP pultrusion profiles are corrosion-resistant, a critical factor in bridge construction. Unlike traditional materials such as steel or concrete, FRP does not rust or corrode, even in harsh environments. This property significantly prolongs the lifespan of pedestrian bridges while reducing maintenance costs. Moreover, FRP pultrusion profiles provide design flexibility. They can easily be tailored to meet specific project requirements, allowing for the creation of unique and innovative bridge designs. The material can be molded into various shapes and sizes, enabling the construction of aesthetically pleasing pedestrian bridges. Furthermore, FRP pultrusion profiles possess excellent mechanical properties, including a high strength-to-weight ratio and fatigue resistance. This ensures that the bridge can withstand the loads and stresses imposed by pedestrian traffic over an extended period. Lastly, FRP pultrusion profiles are non-conductive, making them a safe choice for pedestrian bridges. In areas where there are overhead power lines or electrical equipment, the non-conductive nature of FRP reduces the risk of electrical accidents. In conclusion, FRP pultrusion profiles are a suitable option for constructing pedestrian bridges due to their lightweight, corrosion-resistant, customizable, and mechanically strong properties. Their usage can result in durable, low-maintenance, and visually appealing bridges that provide a safe and efficient means of pedestrian transportation.

- Q: What are the typical dimensions and sizes of FRP pultrusion profiles?

- The typical dimensions and sizes of FRP pultrusion profiles vary depending on the specific application and manufacturer. However, common dimensions range from small profiles measuring around 5mm to larger profiles exceeding 100mm in width or diameter. Lengths can also vary, typically ranging from a few meters to several meters.

- Q: Can FRP pultrusion profiles be used in the construction of safety barriers?

- Indeed, FRP pultrusion profiles prove to be highly effective in the construction of safety barriers. When it comes to safety barrier applications, FRP pultrusion profiles surpass traditional materials like steel or concrete in numerous ways. To begin with, the strength and durability of FRP pultrusion profiles are remarkable. With their high tensile strength, these profiles can withstand substantial loads and impacts without deforming or breaking. Consequently, they are well-equipped to endure the forces that safety barriers may face, such as vehicular collisions or other accidents. Moreover, FRP pultrusion profiles possess a lightweight nature. When compared to steel or concrete, FRP is significantly lighter, which facilitates transportation, installation, and handling during construction. The reduced weight of FRP also proves advantageous in terms of ease of installation and cost-effectiveness. In addition, FRP pultrusion profiles boast excellent corrosion resistance. Unlike steel, FRP remains impervious to rust or corrosion, which can compromise the barrier's integrity and safety over time. This makes FRP particularly suitable for safety barriers exposed to outdoor environments or harsh weather conditions. Furthermore, FRP pultrusion profiles are non-conductive and non-magnetic, which presents advantages in certain safety barrier applications. For instance, in areas where electrical or magnetic interference poses a concern, such as near power lines or sensitive equipment, FRP barriers can provide an additional layer of safety by avoiding potential electrical or magnetic hazards. All in all, FRP pultrusion profiles offer a dependable and efficient solution for constructing safety barriers. Their strength, durability, lightweight nature, corrosion resistance, and non-conductive properties render them a suitable choice for a wide range of safety barrier applications.

- Q: Can FRP pultrusion profiles be used in telecommunications applications?

- Yes, FRP pultrusion profiles can be used in telecommunications applications. FRP (Fiber Reinforced Polymer) offers several advantages such as high strength-to-weight ratio, corrosion resistance, and electrical insulation properties, making it suitable for telecom infrastructure like antenna supports, cable trays, and enclosures. Additionally, FRP pultrusion profiles can be customized to meet specific design requirements, making them a versatile choice for telecommunications applications.

- Q: Can FRP pultrusion profiles be customized or tailored to specific project requirements?

- Yes, FRP pultrusion profiles can be customized or tailored to specific project requirements. They can be designed and manufactured in various shapes, sizes, and configurations to meet specific project needs, such as load-bearing capacity, stiffness, corrosion resistance, and thermal properties. Customization options also include adding features like brackets, holes, or reinforcements to ensure the profiles are optimized for the intended application.

- Q: Can FRP pultrusion profiles be used in the construction of modular buildings?

- Modular buildings can utilize FRP (Fiber Reinforced Polymer) pultrusion profiles. These profiles possess various advantages that render them suitable for modular construction. To begin with, FRP pultrusion profiles are not only lightweight, but also highly durable and strong. This makes them perfect for modular buildings, where reducing weight is crucial for transportation and assembly. In fact, the strength-to-weight ratio of FRP pultrusion profiles often surpasses that of traditional construction materials like steel or concrete. Furthermore, these profiles are resistant to corrosion, chemicals, and weathering. This becomes particularly significant for modular buildings, as they may face different environmental conditions during transportation and on-site assembly. The corrosion resistance also guarantees the longevity and durability of the modular building. Moreover, FRP pultrusion profiles can be designed to possess excellent thermal insulation properties. This proves advantageous for modular buildings that prioritize energy efficiency, as it helps minimize heating and cooling costs. Additionally, these profiles are easily shaped and customized to meet the specific requirements of the modular building design. This versatility allows for the creation of intricate and complex structural components, thereby facilitating the modular construction process. Furthermore, FRP pultrusion profiles are non-conductive, which enhances safety in modular buildings. Their inability to conduct electricity makes them appropriate for applications necessitating electrical insulation. In conclusion, FRP pultrusion profiles offer a viable choice for constructing modular buildings due to their lightweight, durability, corrosion resistance, thermal insulation properties, versatility, and non-conductive nature. These attributes make FRP pultrusion profiles a reliable and efficient solution for modular construction projects.

- Q: Are FRP pultrusion profiles resistant to high-pressure or corrosive fluids?

- FRP (Fiber Reinforced Polymer) pultrusion profiles possess a general resistance to high-pressure and corrosive fluids. The combination of reinforcing fibers and the polymer matrix in FRP pultrusion profiles yields exceptional chemical and fluid resistance, including corrosive substances. Often, the corrosion resistance of FRP pultrusions rivals or surpasses that of traditional materials like steel or aluminum. Moreover, FRP pultrusion profiles offer the advantage of withstanding high-pressure applications. The inherent strength and stiffness of reinforcing fibers, such as fiberglass or carbon fiber, combined with the resin matrix, enable FRP pultrusions to handle high-pressure environments without failure or deformation. In addition, FRP pultrusion profiles can be engineered and designed to meet the specific requirements of various fluid environments. Manufacturers have the ability to select the appropriate resin system and reinforcement materials, providing the desired level of resistance to specific corrosive fluids. This customization ensures that FRP pultrusion profiles are tailored to specific applications, guaranteeing long-term durability and performance in high-pressure and corrosive fluid conditions. Nevertheless, it is essential to acknowledge that the resistance of FRP pultrusion profiles to high-pressure or corrosive fluids may differ depending on the resin system, reinforcement materials, and specific chemicals involved. Consequently, it is crucial to consult with the manufacturer or a qualified engineer to determine the suitability of FRP pultrusion profiles for a particular fluid application.

- Q: Are FRP pultrusion profiles resistant to humidity or moisture?

- FRP pultrusion profiles exhibit remarkable resistance to humidity and moisture. Their inherent ability to repel water absorption stems from the amalgamation of fiberglass reinforcement and a polymer resin matrix. Unlike conventional materials such as wood or metal, FRP pultrusion profiles remain unaffected by moisture or heightened humidity levels, as they neither expand, distort, nor corrode. This moisture resistance renders FRP pultrusions suitable for a diverse array of applications spanning across industries like construction, infrastructure, and marine environments. Moreover, the resistance to moisture can be further bolstered by applying additional protective coatings or surface finishes to FRP pultrusion profiles, thereby escalating their resilience against humidity and moisture.

- Q: Can FRP pultrusion profiles be used in the construction of offshore platforms?

- Yes, FRP pultrusion profiles can be used in the construction of offshore platforms. FRP, or fiber-reinforced polymer, offers excellent corrosion resistance, high strength-to-weight ratio, and durability, making it suitable for the harsh marine environment. These profiles can be customized to meet the specific requirements of offshore platforms, providing structural support and stability while minimizing maintenance needs.

Send your message to us

FRP Pultrusion Profiles - Fiber Glass Reinforce Plastic Pultruded Handle

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 50000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords