FRP Machine Hydraulic System in High Quality of New Design

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

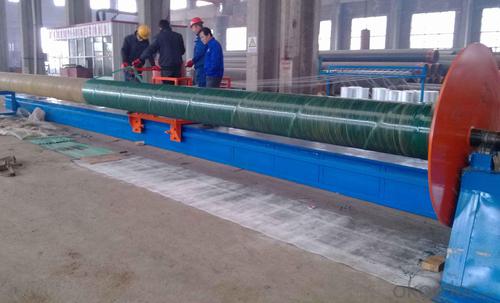

FRP Machine Hydraulic System in High Quality of New Design

Product Description:

1.The FRP production line occupe 20-30M at length, 3 meter at width, about 60-100square meter

2.The main machine is steel structure, stainless steel panel, side panle is paint.

3.Traction gantry make ordered according to requestd length.

4.Hydraulic station: we used the latest technology: pump is multi-group pump source (to ensure stability in forward speed.) Hydraulic parts are made of stacked clip (easy maintenance), and the tension and clamping force can make stepless adjustment. Traction speed with precision throttle, to ensure the stability of traction speed, and stepless speed adjustment of the traction. Hydraulic station with switch, so as to control the hydraulic oil heating up and down,so as to ensure the normal operation of the hydraulic system.

5.Using function: it have single and double manually operated gantry and double gantry automatic reciprocating running function. Automatic intermittent time can be automatically settled, and the actual production tension can be feedback by sensor.

Product Features:

1. Traction gantry make ordered according to requested length

2. It has single and double manually operated gantry and double gantry automatic reciprocating running function.Automatic intermittent time can be automatically set, and the actual production tension can be feedback by sensor.

3. Three-stage temperature control of thermal temperature control device, to achieve automatic control of heating temperature of the mold.

Product Advantages:

1) Convenient and reliable installation, low construction expenses

2) Excellent heat-insulation property from minimum thermal conductivity

3) Light weight, convenient to transport and handle, good for labor-saving.

4) Smooth inner walls reduce pressure loss and increase flow speed

5) Excellent design ensure suitability for both exposed and hidden installation

6) Recyclable, environment-friendly, accords with GBM standards

Product Parameter:

Product name | FRP Machine Hydraulic System in High Quality of New Design |

Material composition | Fiberglas Reinforced Plastic |

Resin type | FRP Grating Machine |

Color | Black , white , red , green , yellow , blue , grey or customized color |

Surface material | Smooth,GritFine grit,Concave,Grit cover,Chequer cover |

Dimension(L*W*H) | 19x19x38x38mm |

Certificate | ISO9001 |

Feature | Aging-Resistant,insulation,corrosion resistance |

Keywords | FRP grating |

Size | Customised Size |

product keywords | frp molded grating machine |

FAQ:

Q1:How Can I Get A Sample?

A1:You can get samples by communicate with our export sales.

Q2:How Long Is Delivery?

A2:Delivery time will be30-45days according to order quantity.

Q3:What Is The MOQ?

A3:MOQ depends on different items.

Product Pictures:

Our services:

1. Providing professional technical support.

2. Send the product catalogue and instruction manual.

3. Personal call or visit is warmly welcome.

4. We provide you with aftersales installation, trainning and one year warranty.

- Q: What kind of equipment do household workshops need to process plastic products? Can you make money? What are the sales channels?

- The biggest investment is the injection molding machine, as well as three-phase power, it is best to understand the machinery will repair the mold, there is a stable processing order, you do not need to sell it!

- Q: Rubber, plastic, machining specialty, which university is good?

- I think Qingdao University of Science & Technology is good, research and production integration, employment is no problem.

- Q: I'd like to open a waste plastics processing plant. What should I pay attention to? What machines are greener? Can you find 5T every day?

- Raw material blowing factory is estimated to have a lot of it. You can go to Tongcheng to see, plastic town ah...

- Q: Environmental impact of foam plastics reprocessing

- Environmental impact of foam plastics reprocessingAt present, the production of foam has been a small production process of pollution, but the investment is large, if absolute pollution is impossible! Production waste and sewage discharge contain many toxic components, because the sodium stearate in it reacts with oxygen nitrogen to form toxic substance. It is a complex compound, but it is a slow process.Moreover, the "waste foam" is the so-called "white pollution", there is a lot of harm.

- Q: I do not know the classification details and processing procedures, as well as the purchase of such equipment, the need for experienced master guidance, you can also join the cooperation,

- Different kinds of waste plastics have different characteristics. As far as impurity content is concerned, waste materials in the middle and outer corners of the factory produce impuritiesThe content of less than 0.1%, piled up scrap for a period of time and other products used for% impurity content 0.1 ~0.5%, mixed with aluminum, cloth and paper composite plastic waste impurities are often more than 10%. For used waste plastics,According to different use conditions, will include ultraviolet radiation, heat, oxygen aging effect, pollutants.Ring. For different shapes of waste plastics, the volume density of materials after crushing is very different, film, sheet, flatThe volume density of the crushing material is smaller, which is a problem that must be considered in the process of waste plastics recycling and granulation.Two. Pretreatment of waste plasticsFrom discarded packages, such as bags, shopping bags, bottles, cans, boxes and waste agricultural film waste plastics, inPretreatment prior to granulation. The pretreatment process mainly includes classification, cleaning, crushing and drying.Classification work is the classification of miscellaneous waste plastics products according to the type of raw materials and product shapes classification. By raw materialsClass sorting requires operators to have a good knowledge of identifying plastic varieties, and the purpose of sorting is to avoid different speciesThe resulting polymers are incompatible with recycled materials and have poor performance. They are classified according to the shape of the product to facilitate the use of waste plasticsThe crushing process can be carried out smoothly, because the film, flat and fabric used in crushing equipment with some thick and hard wareThe crushing equipment often can not replace each other.

- Q: What kind of equipment do we need? How much is the approximate cost? Seek your heroes guidance and guidance!

- Equipment include: film blowing machine, bag machine, punching machine, printing machine, etc., to invest one hundred thousand up and down, but also need a few tons of raw materials as a turnover, and then start production, I do not know very well, just listen to someone else said...

- Q: Which kind of engineering plastics has good processability?It requires small deformation and high machining accuracy when subjected to force

- Organic glass rods and plates, PTFE rod material, nylon rod, PVC sheet and other mechanical processing performance is good.

- Q: I would like to open a small plastic daily necessities processing factory, want to buy such as plastic buckets, plastic basins, plastic small bowl machinery!

- Similar processing machinery, you can go to the machine processing and other similar websites to check

- Q: What kind of equipment does the groove on the PP plastic board work on?

- It can be machined with a shaper or engraving machine

- Q: Where are home plastic products, plastic products for daily use, plastic products processing, plastic products, mold

- You are looking for people to give you the processing mold, is it, then you go to the hook online to find ah, above doing this factory a lot

Send your message to us

FRP Machine Hydraulic System in High Quality of New Design

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches