FRP Composite Filament Winding Pipe Machine with favorable price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 70 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

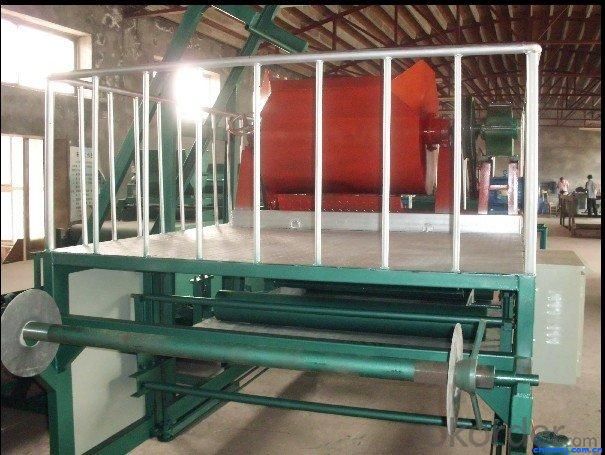

1.FRP drain pipe/marine pipe production line

2.FRP tube continuous production line

3.FRP storage tank production line

4.FRP cable protection production line

5.FRP heat insulating tube production line

6.FRP oil pipe/high pressure/low pressure pipe production line

7.FRP vertical tank production line

Product Features:

1. Low loss, low energy consumption, power consumption per unit output value of the shortage of 1%;

2. Adaptability: the production of thread left or right, different pitch and different specifications of the anchor rod and rebar;

3. Product performance: forming full thread anchor rod technical indicators in line with international standards requirements;

4.High production efficiency.

Product Advantages:

1) Convenient and reliable installation, low construction expenses

2) Excellent heat-insulation property from minimum thermal conductivity

3) Light weight, convenient to transport and handle, good for labor-saving.

4) Smooth inner walls reduce pressure loss and increase flow speed

5) Excellent design ensure suitability for both exposed and hidden installation

6) Recyclable, environment-friendly, accords with GBM standards

Product Parameter:

Product name | FRP Composite Filament Winding Pipe Machine with favorable price |

Material composition | Fiberglas Reinforced Plastic |

Resin type | FRP Grating Machine |

Color | Black , white , red , green , yellow , blue , grey or customized color |

Surface material | Smooth,GritFine grit,Concave,Grit cover,Chequer cover |

Dimension(L*W*H) | 19x19x38x38mm |

Certificate | ISO9001 |

Feature | Aging-Resistant,insulation,corrosion resistance |

Keywords | FRP grating |

Size | Customised Size |

product keywords | frp molded grating machine |

FAQ:

Q1:How Can I Get A Sample?

A1:You can get samples by communicate with our export sales.

Q2:How Long Is Delivery?

A2:Delivery time will be30-45days according to order quantity.

Q3:What Is The MOQ?

A3:MOQ depends on different items.

Product Pictures:

- Q: Consult, small toys, plastic products how to shine? What kind of machine or what kind of abrasives do you need? The swordsman knows to ask for help, if feasible, and to have a heavy score! This toy is made of diamond! It's about three or four centimeters in size! Urgent!

- One is to start from the mold and make the inner surface of the mold smooth!One is starting from the material, to make high light products, first of all, there must be good raw materials, and secondly, to have a good stain, high light color powder, to achieve free spraying, high light injection molding, first of all need to use high gloss plastic material.

- Q: What kind of production equipment will be needed for plastic processing plants for daily necessities?

- You need to have a simple point injection molding machine (injection molding machine according to your size, injection molding products) cooling water circulation system, but also have a scrap machine, if you do have a best particle granulator, should be so much.

- Q: How much is the general control of plastic products profit? Thank you

- This, see the other people give a single, you give the unit price how many, not necessarily, have much, have little

- Q: Environmental impact of foam plastics reprocessing

- Environmental impact of foam plastics reprocessingAt present, the production of foam has been a small production process of pollution, but the investment is large, if absolute pollution is impossible! Production waste and sewage discharge contain many toxic components, because the sodium stearate in it reacts with oxygen nitrogen to form toxic substance. It is a complex compound, but it is a slow process.Moreover, the "waste foam" is the so-called "white pollution", there is a lot of harm.

- Q: shopping bags, what equipment prices? Raw material type and material price? Please expert advice

- It is better to make plastic parts than plastic ones

- Q: The difference between plasticization and processability of plastics in extrusion process

- I. Introduction of extruderIn the screw extruder is under the action of the molten plastic extrusion through fixed shape extrusion, water cooling after cutting in the traction machine under the same section is mainly used for a variety of products. A large number of continuous production, such as tube, rod, profile, also can be used for plastic modification and granulation. The basic mechanism of extrusion is very simple a screw in the cylinder to rotate and move forward the plastic. The screw is actually a ramp or slope that is wound around the center layer. The aim is to increase the pressure to overcome the greater resistance. Is an extruder, there are 3 kinds of resistance to overcome: solid particles (feed) on the cylinder wall friction and screw rotation before laps (feed) the mutual friction between them; melt in the cylinder wall adhesion; melt pushed forward when the resistance of the internal logistics.

- Q: How are the plastic products made of this texture processed?

- Plastics processing technologyPlastic forming process. It is a general term for various processes that convert synthetic resins or plastics into plastic products. It is a larger manufacturing sector in the plastics industry. Plastic processing generally includes plastic batching, molding, machining, bonding, modification and assembly. The latter four processes are carried out after the plastic has been molded into products or semi-finished products. It is also called plastic two times processing.Mixed ingredientsPlastic processing of raw materials, in addition to the polymer, usually also added a variety of plastic additives (such as stabilizer, plasticizer, lubricant, coloring agent, reinforcing agent and filler etc.), to improve the performance of molding process and product or reduce the cost of products. The additive and the polymer are mixed and evenly dispersed into powder, also called dry mixed material. Sometimes, the powder is also processed into pellets. The powders and pellets are referred to as synthetic or moulded plastics.

- Q: What kind of equipment do you need for the food market? How much would you like to invest? What about the profit?

- The first said equipment 1 blowing machine 2 printing machine 3 bag making machine 4 mill material if want to make your own words also need about 27000 granulating machine, film blowing machine, printing machine if printing a color around 10 thousand, if 2 more than 20000 more than 20000 color printing, bag making machine semi-automatic, fully automatic ranging from 4-5 million, 3500 mill more than 20000, granulator, raw materials are polyethylene, if the price of raw materials is a new material price 11000 tons, if it is recycled about 7000 of us production of complete sets of equipment

- Q: What equipment? How much money do not.. at first. There are several sets of injection molding machine can be about 2... Mainly plastic injection molding. The ABS PA PE PP PVC... Etc. in this area. Please know that a friend told Kazakhstan. Thank you.

- 3. cooling tower or water cooler {if cooling pool is small, buy}The production material crushing and recycling of the 4. mill {}5. mould temperature machine {product on mold temperature requirements higher, buy}6. oven {dry on the material, it is recommended to buy directly installed on the machine, drying faster, floor type, because there are several kinds of materials, while drying, the temperature is not good control.7. blender {material color or when adding material}8., the mold should be loaded big gourd, small mold can buy a lifting trolley, a set of mold tools.

- Q: When the engineering plastics in the processing, because it is not often around breaking chip, tool and workpiece, not only affects the working efficiency, but also the workpiece surface galling, do not know can not think of a way from the cutting tool and cutting amount? Who can give me some good advice? Please.

- Superfine base material, uncoated blade and forced chip breaker can be used.

Send your message to us

FRP Composite Filament Winding Pipe Machine with favorable price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 70 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords