FRP automatic glass wool tank making machine with high quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 50 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

FRP automatic glass wool tank making machine with high quality

Product Description:

1.FRP drain pipe/marine pipe production line

2.FRP tube continuous production line

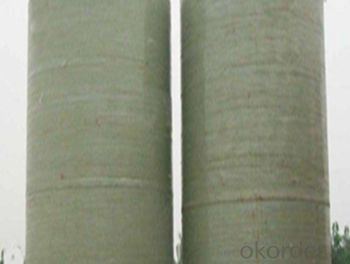

3.FRP storage tank production line

4.FRP cable protection production line

5.FRP heat insulating tube production line

6.FRP oil pipe/high pressure/low pressure pipe production line

7.FRP vertical tank production line

Product Features:

1.High precision winding pattern

2.High productivity and low energy consumption

3.Simple installation and maintenance

4.Industrial computer control, easy in operation

Main Product Features:

1. Easy operation based on PLC intellectual control system. Only short-term training can make operators complete production independently.

2. Unique arithmetic on temperature control makes oven heating fast, temperature control precise. Which improve quality of products, reduce energy consumption and shorten the preparing time effectively.

3. Roving chopper speed can be synchronous with the production line.

4. Special cross cutting machine and good synchronization performance make cutting accurately.

5. All the machine parts adopt international standard steel make machine with high stability.

6. System failure can be automatically alarmed and show fault point. Make maintenance easily.

7. Particular parts adopt special purpose wire, durable in use.

8. Size and layout of machine can be made according to customer requirements.

Product Parameter:

Name | FRP automatic glass wool tank making machine with high quality |

Brand | CMAX |

Weight | 8T |

Dimension(L*W*H) | 900x660 X1700 |

Power | 37KW |

Voltage | 380V 50HZ |

Type | Pipe Production Line |

Certification | ISO9001 |

Appilication | Pipe |

Raw material | PE |

Place of Origin | Hebei, China (Mainland) |

Color | Customized |

Product Pictures:

- Q: I need to know where to buy the equipment and what I need to do

- PVC fiber reinforced hose machine is suitable for the plastic flexible pipe, provide first-class service characteristics of pressure liquid conveying water Henan Anyang HuaSu Machinery Manufacturing Co. Ltd. fly for you: the best quality, best price. High output and low power consumption

- Q: What do you understand in the early stage and how much equipment are needed for the preparation?. Thank you

- Then don't do it. Baidu can't support you in such a big deal. Because big bosses rarely disclose business experience on Baidu - find a reliable master or technician and learn from it

- Q: My home is the county seat, want to open a waste plastic recycling, and then processed into plastic particles factory, do not know how the market? If there is cooperation between manufacturers, the best production, processing can also be.

- Wu Fei Yang waste plastic recycling and granulating machine to help you open a waste plastic recycling processing into plastic particles factory! Sales can give you a few! Manufacturers cooperate with production or processing is also possible! But the timing is uncertain! Henan Anyang Wu Fei Yang presses accumulated industry's most advanced technology and management experience, plastic machinery design concept of the supremacy of users, emphasizing the production and quality inspection process excellence, accessibility consultant, guarantee the perfect customer service service is our service tenet. We are not only producing a professional manufacturer of plastic extrusion lines, but also a service provider who will be required to produce the appropriate products,

- Q: Would you please use the collected nylon and plastic film to wash them and machine them?

- The particles are collectively called colloidal particles". Mainly used in the quality of plastic products are not demanding. Such as cabbage tube, Christmas leaves etc..

- Q: I don't know what kind of machine is needed. How can I sell the material after processing? Is there anyone?I want to make a waste plastic (plastic bottle) small processing at home, I don't know what kind of machine is needed. How can I sell the material after processing? How much money does it cost?. Seek expert advice, the more detailed, thank you!

- This is HDPE's.. PET general crushing cleaning, selling chemical fiber plant, HDPE generally sell granulation plant, cleaning, and some injection molding factory is also useful. Just break it and use a crusher. Crushing equipment from several thousand to twenty thousand or so, some home recycling, there are door-to-door.

- Q: What plastic products are made out of machines? Is it an injection molding machine?

- According to the process, there are many kinds of processing equipment, not only the injection molding machine, as well as extruder.

- Q: What kind of equipment do you need for plastic basin processing? How much is it?

- According to the size of plastic injection molding machine plastic products, the weight and volume of the plastic products you are optional I think a 1000 grams of plastic injection molding machine, used in the production of small washbasin, plastic baskets, plastic boxes; take a 3000 grams of plastic injection molding machine, used in the production of plastic containers, large plastic baskets, plastic barrels beer box, etc..

- Q: I'd like to know all the machine names in the plastics processing industry.I would like to ask the professionals to give me some reference materials or tell them directlyThanks very much。

- I. Introduction of extruderIn the screw extruder is under the action of the molten plastic extrusion through fixed shape extrusion, water cooling after cutting in the traction machine under the same section is mainly used for a variety of products. A large number of continuous production, such as tube, rod, profile, also can be used for plastic modification and granulation. The basic mechanism of extrusion is very simple a screw in the cylinder to rotate and move forward the plastic. The screw is actually a ramp or slope that is wound around the center layer. The aim is to increase the pressure to overcome the greater resistance. Is an extruder, there are 3 kinds of resistance to overcome: solid particles (feed) on the cylinder wall friction and screw rotation before laps (feed) the mutual friction between them; melt in the cylinder wall adhesion; melt pushed forward when the resistance of the internal logistics.

- Q: What kind of machine is needed for the production of plastic products?

- Seventy thousand or eighty thousand an injection molding machine, a crushing machine, a drying machine forty thousand or fifty thousand, workshop, rent, labor, water and electricity to ten thousand months Duoliangwanyi, mold materials, another operator, of course cost large scale is low.

- Q: Is there a difference in melt index before and after processing?

- If no additives are added during processing, the melt index is the same as that before processing.

Send your message to us

FRP automatic glass wool tank making machine with high quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 50 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches