Automatic FRP Gutter Making Machine with High Quality with Good Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 25 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

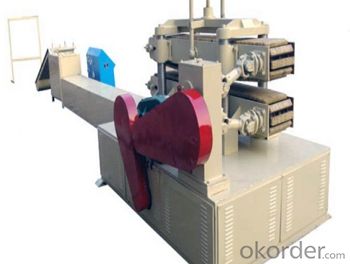

Automatic FRP Gutter Making Machine with High Quality with Good Price

Product Description:

1.Gutter cold roll forming machine can bend the roll formed pipe, and let the drainpipe and the bending connect to be the whole.The product after roll forming has long working time than the tranditional ppc pipe, and not aging.

2.Gutter cold roll forming machine is composed of uncoiler, the feed leading table, the main machine, the formation cutting device, hydraulic system, control system and the product bracket.

Product Features:

1.It is used in industrial fields

2. Beauty appearance.

3.Thermal insulation and energy saving.

4. Easy installation

5.excellent heat resistance and pressure resistance

Product Parameter:

Name | Automatic FRP Gutter Making Machine with High Quality with Good Price |

Brand | CMAX |

Weight | 5T |

Dimension(L*W*H) | 8.5*1.8*3.2m |

Power | 50KW |

Voltage | 220V 50HZ |

Product Type | FRP Machinery |

Certification | ISO9001:2008 |

Application | Wide Use |

Raw material | Fiber Reinforced Plastic |

Place of Origin | Beijing, China (Mainland) |

Color | Customized |

Warranty | 13 Months |

Time of Delivery | 30-45 days |

Product Pictures:

FAQ:

Q: Why we are your best choice?

A:We have direct factory and many years of export experience, and offer the best price with high quality product,timely delivery, also have good after-sales service, therefore with good reputation on boards and with many clients have good long-term business relationship.

Q: Can I order the product with special size?

A: Of course you can, also we will produce the products according to your detail requests.

- Q: Who knows Guangdong province processed waste plastic particles Factory where. Thank you

- Yes, they do more, and each place has a different salary.

- Q: What is plastic processing of moulds?

- Although the structure of the mold may be varied because of the variety and performance of plastics, the shape and structure of plastic products and the type of injection machine, but the basic structure is consistent. The mold is mainly composed of pouring system, temperature regulating system, molding parts and structural parts. The gating system and molding parts are in direct contact with the plastic parts and products as plastics and change, is the most complex in the mold, the biggest change, part of the processing requirements of the highest accuracy and smoothness.Pouring system refers to the flow of plastic from the nozzle into the mold cavity, including the main road, cold material hole, diversion channel and gate. Forming parts are parts of the shape of the product, including moving die, fixed mold and cavity, core, forming rod and exhaust port, etc..China plastic mould in promoting high technology driven and pillar industry application requirements, formed a huge industrial chain, from upstream raw materials industry and machining and testing equipment to the downstream machinery, automobile and motorcycle, household appliances, electronic communications, building materials and other major industrial applications, the development of a plastic mold vitality.With the rapid development of China's automotive, home appliances, electronic communications, building materials.

- Q: How much is the general control of plastic products profit? Thank you

- This, see the other people give a single, you give the unit price how many, not necessarily, have much, have little

- Q: How much does it cost to run a small waste plastics processing plant?

- Hello, you need to tell me in which city and set up factories in general a small waste plastic particles Factory granulation machine and rolling machine related maintenance tools almost one hundred and twenty thousand or so this is the lowest level for the continuous operation of the workers to four hundred pounds or twenty total count down several flat covering but the mechanical and artificial need not one hundred and eighty thousand factory covers an area of such the words of small plastic granulation plant can take 25

- Q: Where do engineering plastics processing best?

- Organic glass rods and plates, PTFE rod material, nylon rod, PVC sheet and other mechanical processing performance is good.

- Q: What kind of equipment do we need? How much is the approximate cost? Seek your heroes guidance and guidance!

- Equipment include: film blowing machine, bag machine, punching machine, printing machine, etc., to invest one hundred thousand up and down, but also need a few tons of raw materials as a turnover, and then start production, I do not know very well, just listen to someone else said...

- Q: What plastic products can ABS be used for?

- 4. office equipment ABS has excellent impact resistance, good dimensional stability and rigidity. Forming, housing for manufacturing all kinds of office equipment, economic and practical. Such as fax machines, photocopiers, typewriters and computer monitors and other office equipment. The higher requirement on the fire, so usually are made of flame retardant ABS grade manufacturing.5. die model because ABS plastic machining performance, light weight, low price, in recent years has been widely used to mold model making industry, automobile, electronic appliances, machinery and equipment testing instrument. The rapid forming machine model Dimension is currently the world's most advanced ABS manufacturing standard stereo prototype as raw materials, then you can test of new product appearance, suitable degree and related functions. With the best price in similar products.

- Q: I don't know what kind of machine is needed. How can I sell the material after processing? Is there anyone?I want to make a waste plastic (plastic bottle) small processing at home, I don't know what kind of machine is needed. How can I sell the material after processing? How much money does it cost?. Seek expert advice, the more detailed, thank you!

- This is HDPE's.. PET general crushing cleaning, selling chemical fiber plant, HDPE generally sell granulation plant, cleaning, and some injection molding factory is also useful. Just break it and use a crusher. Crushing equipment from several thousand to twenty thousand or so, some home recycling, there are door-to-door.

- Q: Laizhou plastic processing plastic machinery and equipment, which is more reliable, relatively good?

- you have this problem too vague, but also do not know you to play some bottom in figure what product, change a problem to try again

- Q: ABS plastic processing flow

- ManufacturabilityABS is an amorphous polymer with no apparent melting point. Because of its grades, grades, in the injection molding process should be based on the different grades to formulate the appropriate process parameters, generally in 160X: above, 270C can be formed below. Because the temperature is too high, there is a tendency to destroy the rubbery phase in ABS and begin to decompose over ZTOC. In the process of molding, ABS has better thermal stability, wider range of choice, and it is difficult to degrade or decompose. Moreover, ABS melt viscosity is moderate, its fluidity is better than the polyvinyl chloride, the polycarbonate and so on, moreover, the melt cooling solidification speed is relatively quick, generally in 5 ~ 15S can be cold solid. The mobility of ABS is related to both injection temperature and injection pressure, where the injection pressure is slightly more sensitive. Therefore, in the process of forming hand from the injection pressure to reduce the melt viscosity, improving the filling performance. ABS because of the different components, the performance of different water absorbent and adhesion, the adhesion and absorption of water between 0.2 ~ 0.5% and sometimes up to 0.3 ~ 0.8%, in order to get the products ideal for the drying process, before molding, the moisture content below 0,1%. Otherwise, the surface will appear on the silver bubble,.

Send your message to us

Automatic FRP Gutter Making Machine with High Quality with Good Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 25 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches