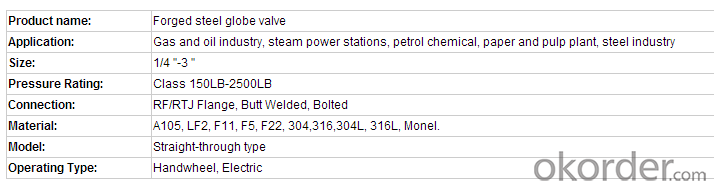

Forged Steel Globe Valve RF/RTJ flange, butt welded

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 set

- Supply Capability:

- 3000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

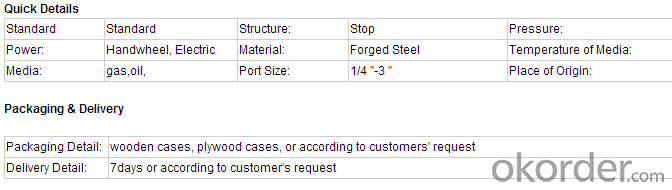

Specifications:

Size: 1/4 "-3 "

Connection: RF/RTJ Flange, Butt Welded

Pressure Rating: Class 150LB~ Class 2500LB

Material: A105,LF2,F11,F5,F22,304,316,304L,316L,Monel.

Structural Features: Bolted bonnet, welded Bonnet, Reduced bore, Full bore

Certification:ISO9001,API600,CE0036

Guarantee: 18months ; OEM offer

Design Standard:

Design & Manufacture Std.: ASME B16.34,BS1873, JIS B2071,B2081

Inspection and Test: API598

Face to Face Dimension: ASME B16.34, BS5352 MSS SP-118

End Flange Dimension: ASME B16.5

Butt-welding End Dimensions to: ASME B 16.25

Threaded End: NPT ANSI B1.20.1, BSP, BSPT,

Socket-weld End: ASME B16.11

- Q: What does LBC mean in a valve?

- LB and 800 are together. 800LB means 800 pounds of stress, and P should be PRESSURE.Valve (Famen) is a control component in the fluid delivery system. It has the functions of closing, adjusting, guiding, preventing reverse flow, stabilizing voltage, shunting or overflow and releasing pressure.Valves used in fluid control systems, from the simplest stop valve to a very complex automatic control system used in a variety of valves, a wide range of varieties and specifications. Valves can be used to control air, water, steam, a variety of corrosive media, mud, oil, liquid metal and radioactive media and other types of fluid flow.

- Q: Is the valve clockwise?

- The valve clockwise rotation of the handwheel is to close the valve, counter clockwise direction is to open the valve, the number above said valve opening rotating the handwheel clockwise along the colonel, to the above number 0 corresponding pointer is completely closed; in counter clockwise direction, to a maximum of 5 numbers above corresponding pointer, is the valve open to the largest degree.

- Q: Where is the Shanghai valve? What brand is good?

- Shanghai Dapu Valve Co. Ltd.Amico jiekelong shield, doing a good job

- Q: I would like to ask how the valve entry, for a new pair, really difficult, what cutaway view, there are other, just contact the valve less than a week, and sometimes it is really difficult to understand. Forget the experienced teacher can be generous with your criticism to later, indebted forever, learn the valve Comrades some help.In a company CAD to relatives as soon as possible to a company, and then slowly improve, I do not know what is the request of the novice, and how to start as soon as possible, I am learning routine is: give me a set of valve design drawings, and then I paint it on, do not understand the structure and workshop look. I wonder if you have any good learning methods that can be referred to and supplemented by younger brother

- May learn some basic knowledge of valves, learning in practice, relatively fast.

- Q: In the fire drawing, what valve does the following valve represent?

- This is definitely the sprinkler system. It's a drain valve, a ready valve. You check it. I can't remember it. It has not been drained for a long time.

- Q: I would like to ask, how specific treatment, and compared with the industry?.Is there a constructive answer?

- I have to do the technical sales colleagues is high inside out now before the inside sales revenue is also good about one hundred thousand a year as sales of a great degree of luck the.I do not know what the specific circumstances, what age, in this line for several years, there is the opportunity to communicate with the landlord and make progress together.

- Q: What valve is the FCV?

- FCV, control valve - you can adjust the valve opening according to the required flow

- Q: Where is it installed, what is the role, what is the material, and are there other alternatives instead of this effect?

- Valve packing in the valve under the gland to prevent leakage, you can use ordinary asbestos rope and butter emergency replacement

- Q: What is the BV valve?

- It should be American Copeland company, BV series valves;

- Q: Yongde jiekelong valves and valves of the good faith

- Fujian Xiamen huashenghong Sanitary drainage fittings. Furniture guide rail, hardware, Taiwan locomotive. All of the above are the strongest domestic brands, high quality, stable performance, durable, buy a lifetime warranty, quality products. Domestic airport, water cube, bird's nest are using the above brand accessories.

Send your message to us

Forged Steel Globe Valve RF/RTJ flange, butt welded

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 set

- Supply Capability:

- 3000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords