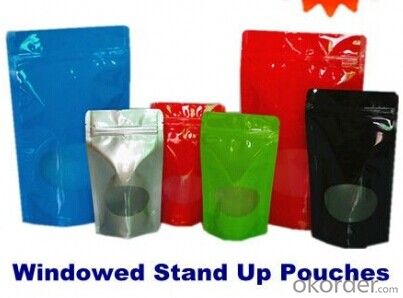

Food Grade Plastic Stand Up Pouch With Window

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 PCS

- Supply Capability:

- 100000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description of Food Grade Plastic Stand Up Pouch With Window:

Food Grade Plastic Stand Up Pouch With Window are processing with imported materials,we have introduced advanced equipment and high manufacturing technology into production lines and we have rich experience in producing plastic bag .can meet your needs by fulfilling your specification in a positive manner .High efficiency and speed are our working style .high quality and competitive price are our pursuit.

Food Grade Plastic Stand Up Pouch With Window mainly used for packing food such as coffee, tea, snack, powder etc.

2. Main Features Food Grade Plastic Stand Up Pouch With Window:

Excellent quality control

Experienced facotry produced

SGS passed

3. Food Grade Plastic Stand Up Pouch With Window Photos:

4. Food Grade Plastic Stand Up Pouch With Window Specification:

1. Material: PE,LDPE,HDPE with Craft paper etc

2.Size:10*10000px or Customized

3.Thickness:10-200um

5.FAQ of Food Grade Plastic Stand Up Pouch With Window:

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Plastic packing bags can supply you all kind of packing bags you wanted.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: Duck sauce made of pure aluminum foil vacuum packaging bag or transparent plastic?

- A good vacuum packing is recommended.

- Q: How do I remove the self-adhesive label affixed to the plastic bag?

- On the label with wind, a few minutes to unveil the label, the label will fall together with adhesive. Even at the stubborn stickers with traces of essential balm, and fingernails pull, usually can quickly clean up the traces.

- Q: Is the packet in the food package a reducing agent or an oxidizing agent?

- The ingredients of food reducing agents are some vitamins, phenols, iron powder and so on. Because these substances react readily with oxygen, they protect the food from being oxidized,

- Q: Do vacuum packing bags have to be vacuum packed?

- Vacuum packaging bags and vacuum packaging machines are related. Vacuum packaging machine not only can complete vacuum extraction, but also can complete heat sealing packaging in vacuum, and ensure vacuum in vacuum bag can meet the requirement.

- Q: What kind of material is the food packing bag in general?

- Are usually packaged in composite bags, composite materials, polyethylene (PE), polypropylene, nylon, polyester. These are the main membranes. The film is made of stretch film and blow film.

- Q: Dried fish vacuum packaging packing bag can not puncture

- With dried fish, we recommend the use of aluminum foil bag, also can be vacuumized. It has the function of avoiding light and keeping fresh.

- Q: What's the difference between plastic packaging bags and clothing bags?

- Clothing bags and plastic bags are just a general term for packaged products. Bags can also be made in various forms, so the machines are different,

- Q: What material should be used for transparent packing bags? How many cents do you want?

- PVC, English referred to as PVC (Polyvinyl chloride), is a vinyl chloride monomer (vinyl chloride monomer, referred to as VCM) in peroxide, such as azo compound initiator; or in light, under the action of heat polymerization by free radical reaction mechanism of polymerization of polymers. The vinyl chloride homopolymer and vinyl chloride copolymer are collectively referred to as vinyl chloride resins.

- Q: What's the size of the 5 kg vacuum bag, please?

- Custom vacuum packing bag, I recommend to have experience in custom vacuum packaging bag manufacturers, because it can reduce the cost and time for many of you, can give you a lot of packaging design and customized recommendations.

- Q: What are the types of composite packaging bags?

- Folding small packing bag (or ordinary packing bag)A bag of less weight, usually made of single or double layers. For some special packing bags, it can also be made of multi layers and different materials: the packing range is wide, and the packing can be used in liquid, powder, lump and irregular shape.In these packing bags, the packing bags are suitable for transportation and packing, and the general transport packing bags are suitable for external packing and transportation packing. Small package bags are suitable for inner packing, packing and commercial packing.

Send your message to us

Food Grade Plastic Stand Up Pouch With Window

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 PCS

- Supply Capability:

- 100000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords