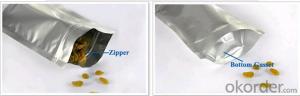

foil lined stand up kraft paper bags good quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 200000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specifications

foil lined stand up kraft paper bags

feature: eco-friendly, food grade, excellent barrier

ideal for tea, coffee, dry food pack

Before confirm the order we need know following:

1,Style of the product?

2,Number of colors to be printed?

3,Content to be printed?

4,Any decoration needed?

5,Approx. size?

6.Usage?

7,Quantity?

Please let me know all your requirement of Vertical Spout Pouch or others,we can customize for you !

- Q: What does "TM" mean in a food package?

- TM is common in foreign trademarks. It is the abbreviation of "trade mark" in English. "Trade mark" means "commercial mark" in Chinese, so "TM" means "trademark""

- Q: Duck sauce made of pure aluminum foil vacuum packaging bag or transparent plastic?

- I did, I saw, salted duck, beef and other good packaging, is the use of the former.

- Q: What kind of material is the urea packing bag made of?

- The main material of urea woven bags consists of polypropylene and polyethylene.

- Q: Three layer coextrusion material for packaging bags

- Five layer co extruded films composed of outer layer of multi ester copolymer, high mechanical strength, the second layer is ethylene methacrylate polymer, the third layer is the fourth layer of polyethylene, polyethylene, the inner layer is modified with ethylene propylene polymer. Five layer co extruded films performance of each layer as outer layer: providing excellent heat sealing and protection, good printing performance; the second layer is connected with the outer layer and third layer; third layer: providing vapor barrier and softness; fourth layer: connection layer and the third layer; inner layer: non-toxic, with compatibility infusion product good, excellent heat sealing and buffering external impact.

- Q: Printing process of packaging bag

- If there is no peritoneal, press the printer faster;

- Q: What material is the surface of the packing bag such as instant noodles, pickled mustard tuber, small bread and so on? Why should we add this layer?

- First, it is easy to heat seal, otherwise only aluminum foil can not be sealed;Two, high barrier plastic film preservation effect is also very good, can increase its number of layers, reduce aluminum foil thickness, thereby reducing costs

- Q: Can the meat with plastic packing bag be pressed directly with a pressure cooker?

- The plastic composite film (bag) products used in food packaging have 8 national and trade standards, and the main standards are divided into physical and mechanical performance indexes and sanitary performance indexes. The indexes of physical and mechanical properties are mainly tensile strength (or tensile strength), elongation, peel strength, heat resistance strength, Charpy impact energy, water vapor permeation amount and the amount of oxygen through the bag, bag, pressure resistance, heat resistance and dielectric performance drop, oil resistance, cold resistance, heat resistance etc.;

- Q: What ink is the food packing bag printed on?

- Because of this, benzene soluble chlorinated polypropylene ink has been gradually eliminated, and in Europe and other developed countries have gradually introduced or banned the use of benzene soluble chlorinated polypropylene ink laws and regulations.

- Q: How about the material difference of food packaging bag?

- Reason: PE has better heat sealing property, which is easy to sealPA has better printability and is used in the outer layer to print beautiful picturesPVDC EVOH, good separation performance, prevent oxidation. The film closed light is good, not easy to see the light of the product is appropriate.Specific more professional, no longer introduce one by one

- Q: What is the difference between package material PETAL and VMPET?

- Packing material:PETAL represents the PET film composite pure aluminum sheet material. Packaging industry called aluminum foil filmVMPET represents an aluminized PET film, which is a high temperature vacuum in which the high purity metal aluminum is uniformly applied to the plastic film. The packaging industry is called aluminized film.

Send your message to us

foil lined stand up kraft paper bags good quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 200000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords