First-level Printed Laminated Bags For Industry Packing

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description of First-level Printed Laminated Bags For Industry Packing:

First-level Printed Laminated Bags For Industry Packing are processing with imported materials, we have introduced advanced equipment and high manufacturing technology into production lines and we have rich experience in producing plastic bag .can meet your needs by fulfilling your specification in a positive manner .High efficiency and speed are our working style .high quality and competitive price are our pursuit.

First-level Printed Laminated Bags For Industry Packing mainly used for packing food such as coffee, tea, snack, powder etc.

2. Main Features Of First-level Printed Laminated Bags For Industry Packing:

Excellent quality control

Experienced factory produced

SGS passed

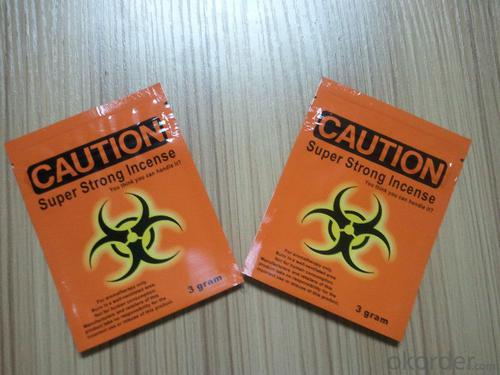

3. First-level Printed Laminated Bags For Industry Packing Photos:

4. First-level Printed Laminated Bags For Industry Packing Specification:

1. Material: PE,LDPE,HDPE with Craft paper etc

2.Size:10*10000px or Customized

3.Thickness:10-200um

5.FAQ of First-level Printed Laminated Bags For Industry Packing:

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Plastic packing bags can supply you all kind of packing bags you wanted.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, we will arrange the factory delivery as soon as possible. The pacific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: What does "TM" mean in a food package?

- Its role is to tell people that it is marked by the graphics or text of the goods or services of trademark, not the name is not advertising. English and "R" is the abbreviation of "register", "register" Chinese means "registered", goods or services on the mark that is told people, it marked the graphics or text but not trademarks, and registered trademarks, protected by law, unauthorized, unauthorized use can not be any other individuals and organizations.

- Q: Duck sauce made of pure aluminum foil vacuum packaging bag or transparent plastic?

- I did, I saw, salted duck, beef and other good packaging, is the use of the former.

- Q: Is the packet in the food package a reducing agent or an oxidizing agent?

- The small bag inside the food package is an antioxidant. Belongs to reducing agent.

- Q: How do you determine the 210mm*300mm package and determine its version and length?

- Length 21 cm, width 30, vertical roll length suggest up to cooperate with compound printing equipment

- Q: What material is the vacuum packing bag, please?

- Vacuum packaging is a general term for flexible packaging composite membrane products. If the temperature is different, there will be a lot of division: there is less than 100 bactericidal, and some need 100 degrees of sterilization, and 121 degrees and 135 degrees.

- Q: What kind of material is the food packing bag in general?

- Are usually packaged in composite bags, composite materials, polyethylene (PE), polypropylene, nylon, polyester. These are the main membranes. The film is made of stretch film and blow film.

- Q: What are the soft and hard sides of plastic bags? Material or process technology?

- On the basic price will be a little higher, the brittle is generally PP or PET is done, some relatively low grade. Soft is generally made of multi-layer coextrusion film, barrier, and feel good. This soft about 27000 yuan / ton, while the PP film generally as long as 17000 yuan / ton, ten thousand tons a difference.

- Q: What material is the surface of the packing bag such as instant noodles, pickled mustard tuber, small bread and so on? Why should we add this layer?

- Aluminum filmThe first consideration of food packaging is the barrier properties of packaging materialsBecause barrier property is good, the preservation time is long, the shelf life is long, the quality can guarantee betterAt present, all food packaging materials, aluminum foil barrier is the best (followed by some high polymer plastics, like EVOH, PVDC, etc.)Therefore, the most common, always in the middle of two layers of plastic film, a layer of aluminum foil, to improve barrier,But why not use aluminum foil packaging alone, but also two or more layers of plastic film?,

- Q: What's the difference between plastic packaging bags and clothing bags?

- Clothing bags and plastic bags are just a general term for packaged products. Bags can also be made in various forms, so the machines are different,

- Q: What's bread packing? Polyethylene film, waterproof cellophane, etc.

- More importantly, the use of aluminum foil / composite or polyethylene composite or aluminum foil / polyethylene composite material. Although this type of packaging is opaque, it protects against loss of vitamin B1 in bread.

Send your message to us

First-level Printed Laminated Bags For Industry Packing

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches