Fireclay Bricks - High Density for Blast Furnace

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

High density Fireclay bricks for Blast Furnace is a kind of insulation material adopting organic matter as ignition loss substance in order to increase the porosity of refractory, which has such advantages as high porosity, small volume density, good insulation effect, high mechanical intensity, small thermal conductivity and long service life. For various industrial kilns & furnaces, it is a kind of essential refractory for energy saving and temperature preservation.

This series of High density Fireclay bricks for Blast Furnace are made of selected high alumina bauxite, kaolin clay, hollow microsphere as the mian material.By shaping at high pressure and sintering at high temperature

Product Applications:

1. Furances of glass,coke oven,electric and so on

2.Furnaces of metallurgy industry, heat treatment furnace

3. Furnaces of chemical industry and construction industry.

Main Product Features:

1. Low porosity,High bulk density.

2. High Cold Crushing strength.

3. High refractoriness under load.

Product Specifications:

1.With 55% Al2O3 min;

2. Refractoriness: 1750C min;

3.For steelmaking furnaces;

4.ISO 9001 Certificate;

5.Custom shape;

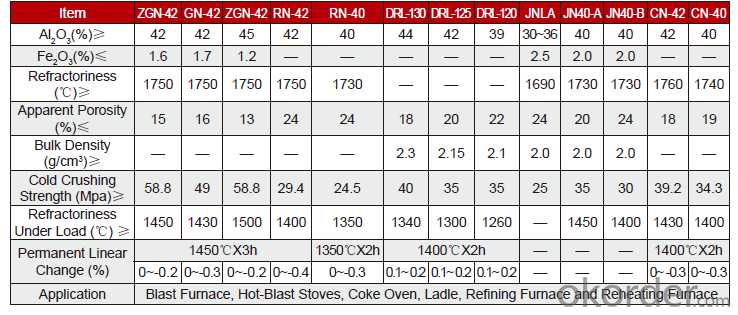

Technical data:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: Can refractory be used to sharpen knife?

- Many factories build a smelting furnace by using this kind of bricks. A special knife grinder can be used to sharpen knife, can on 1. They are sizing and non-sizing refractory bricks respectively. Refractory brick is now a lot of fields and industry will introduce one of the raw materials. Products are divided into two different types, refractory brick as a high temperature resistance of the raw materials. In simple terms, working temperature is 770 DEG C, 580 C and 1, of course, refractory bricks also can be used to sharpen knife, use smooth brick to sharpen, need to choose high hardness

- Q: which kind of refractory bricks do coke oven and oxtongue brick belong to ( ) A, silica?brick B, clay brick C, high alumina brick

- Beef tongue is to regulate the flow of gas, gas flow is not the same, so is the temperature, so choose the temperature resistance brick which is clay brick only.

- Q: How many degrees of refractory brick if its surface turns red, how to test the temperature of refractory brick after it is burnt to red.

- But it depends on materials; for example, if clay brick is pink, it calls underburnt temperature is 700 degrees -900 degrees, paste red is called overdo temperature 1350 degrees -1390 degree, if the color turns heavier, it will be deformation. there are many reasons for refractory bricks sintering

- Q: How to wipe off the white paint on the refractory brick (red).

- Cover the wall gap with tape. . Then paint the bricks. Finally, tear the tape off. .

- Q: How to prevent the refractory bricks from burning to crack?

- This may result from formula. Prevent the refractory bricks from being overweight. Firstly, sintering agent should not exceed the standard, when sintering, bricks must be well piled to piled bricks, and the bricks must be dry.

- Q: What mud is the refractory brick made of?

- The main material of the ordinary refractory brick is clay, the main component is aluminium oxide.

- Q: What is the difference between fused brick and clay brick?

- Electric melting brick with pure alumina and zirconia containing silica 65%, about 34% of the zircon sand in electric furnace melting after internalization into moulds cooling and the formation of the white solid, the petrographic structure by zirconium corundum and plagioclase eutectoid and glass phases, from the phase is corundum phase zirconium plagioclase eutectoid phase, glass phase filling between their crystallization.

- Q: Can mud and salt be used as refractory materials

- Clay can be used as a refractory material, but salt can certainly not be used.

- Q: Which is best of refractory brick press machine?

- Rub press machine have been forced out. Without permanent magnet. The electric screw press machine is suitable for the forming of refractory bricks. Use Kehui switch reluctance to servo motor to drive electric screw press machine, have the ability of high quality electric screw press machine, no water cooling, high efficiency and energy saving, green and environmental protection.

- Q: Can refractory bricks be used to pave roads or build a wall?

- Refractory bricks are used to build a house, no problem

Send your message to us

Fireclay Bricks - High Density for Blast Furnace

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords