Fire Fighting Truck with Tank Capacity of 5000L

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description for Fire Fighting Truck

5000l fire fighting truck

1.Dimension:4*2M

2.capacity:5000l

3.cummins engine:190hp

4.fire fighting truck

Features for Fire Fighting Truck

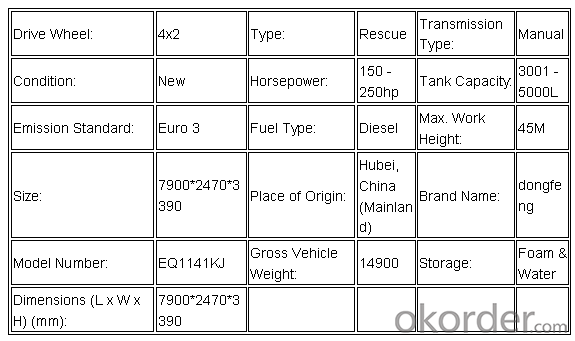

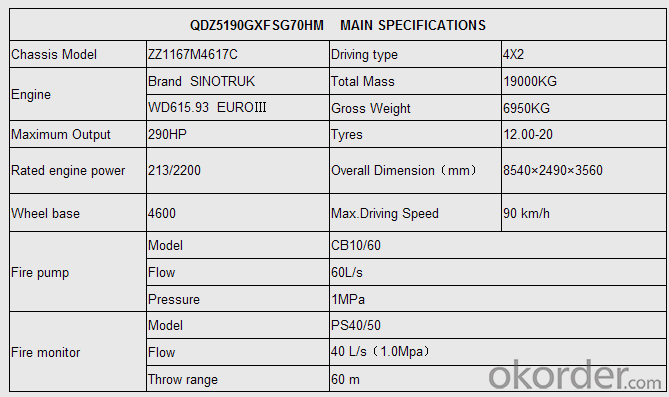

Specification for Fire Fighting Truck

Pictures for Fire Fighting Truck

MOQ for Fire Fighting Truck

Q:What is the function for fire fighting truck?

A:Fire truck is also called as the fire fighting truck and fire engine. It is used to fight fire or for other emergency rescuing specially.

The fire truck is usually kept in fire bureau, and is driven to the accident location by the fire fighter. Most fire trucks are painted in red, but still some rare places that is painted in yellow. The siren is usually taken as the standard device for the truck.

- Q: How many layers of steel wire tyres are used in concrete mixers

- 1200R20 R: represents a wire or a meridian 20: a hierarchy.

- Q: What is the car for concrete

- These trucks are equipped with cylindrical agitating cylinders to carry mixed concrete. During the course of transportation, the mixer will be kept rotating to ensure that the concrete is not frozen. After the concrete is transported, it is usually used to flush the inside of the cylinder to prevent the hardened concrete from taking up space, making the cylinder volume less and less

- Q: s the collapse of four concrete mixer trucks

- The caving degree is 4 cannot be transported by concrete mixer, the slump is put into and out of the tank car. The average slump is 100 to 120mm, and it is better not to transport the concrete transporter, preferably with a construction dump truck.

- Q: What are the three main parts of the concrete mixer car

- The speed reducer, the pump radiator, is to make the mixing tank turn

- Q: Does it affect the ease of mixing too long?

- The site stirring, the quality is not easy to control, the site pollution is serious for the main reason, the construction committee has the file request, so all do not stir in the scene.

- Q: What is the driving license for a concrete mixer truck?

- B2, you can do it directly. But it must be 21 years old and must be taught in permanent residence. The temporary residence is limited to the C series. The tuition fee for Beijing is 2,800 to 3100.

- Q: What can be done to remove the concrete from the concrete mixer truck

- This is the worst case scenario, you don't have to think about it, just change the tank, don't think about how you can save the money. It's a big lesson.

- Q: How many cars do you have for a concrete tanker

- Now the concrete agitator truck is generally measured in the quantity of tank, usually from six square cans to 18 cans, and now it is commonly used in 10-15 cans.

- Q: What is the purpose of the concrete mixer

- The main purpose of the mixer is to transport concrete or slurry that is already in a concrete mixer to the construction site. Due to concrete truck mixer mixing tank is adjustable speed rotating stirring, so the concrete mixer truck transport can maximum guarantee stipulated in the delivery distance and time not segregation, coarse aggregate is not settling, maintain good workability; Mixed soil mixer is used for the construction of hybrid stations and large projects. Another concrete mixer is used for carrying water that can carry the same amount of concrete as the payload.

- Q: Why is the concrete mixer turning on the road?

- Because concrete is according to certain proportion with the mixture of the water cement ratio is one of the important factors, the size of water cement ratio directly determine the quality of concrete. In the process of concrete transportation, which is to keep the concrete maintain form without condensation, otherwise it will make concrete loss have building performance.

Send your message to us

Fire Fighting Truck with Tank Capacity of 5000L

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords