filter net,Sonim oxide and various inclusions

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 20000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

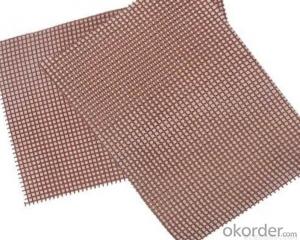

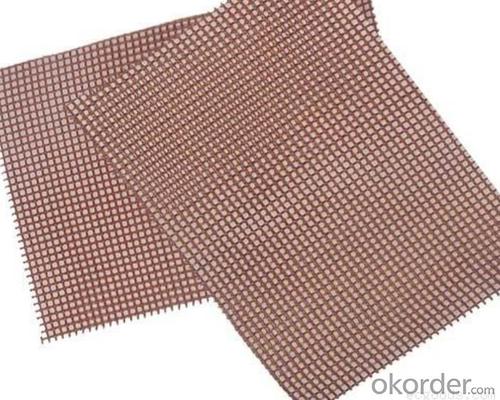

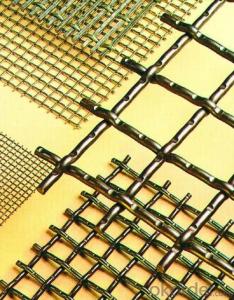

The use of high temperature resistant fiber filter net casting, after the special craft weaving, processing after made products have become series, advanced technology, quality and stability. Compared with other kinds of filter, high temperature resistant fiber casting filter screen has the advantages of low price, convenient use, does not change the casting metal components, filter residue is of good effect, low gas evolution. In addition, it also has the strength of steel high temperature resistance, ablation resistance, good chemical stability, erosion resistant, good melt metal.

Casting, steel casting, iron castings, aluminium castings and other castings, due to various reasons, it is easy to produce slag hole, sand hole, gas hole and other quality problems, thus removing non-metallic inclusion in molten metal, to improve casting yield, improve the quality of castings, has great technical and economic value.

High temperature resistant fiber casting filter screen is widely used to deal with the purification of various metal melt filtration, through the filter, can achieve the following purposes:

1, the effective removal of metal melt bubbles, Sonim oxide and various inclusions and other harmful impurities, thereby eliminating the casting eyelet fundamentally

And slag eyes, trachoma, greatly improve the casting yield, improve the appearance and intrinsic quality of castings.

2, improve the mechanical properties of castings: can make the casting hardness, and surface hardness is uniform and improve the bending strength of the casting.

3, change the graphite morphology, the graphite size decreases, thickness, shape slightly curved.

4, change the machining properties of castings, improve processing efficiency.

Aluminum water, the main varieties of molten iron, molten steel, copper water filtering net, cap type filtering net, meshes are: 0.8X0.8,

1.0X1.0,1.2X1.2,1.5X1.5,2.0X2.0,2.5X2.5等

1.0X1.0,1.2X1.2,1.5X1.5,2.0X2.0,2.5X2.5

Can also be customized according to specific user requirements specification of the products

[Technological index of filtration]

Filtration index of network technology [Technological index of filtration]

The working temperature of the softening point of net type continuous working time of room temperature tensile strength of hair volume scope

The temperature of 1600~1620 DEG C molten steel filter screen 1700 DEG 5[minute] = 16 = 60 small and medium-sized steel casting filter

1400~1450℃ 1700℃ 10[minute] ≥8

The temperature of 1400~1450 DEG C molten metal filtering net 1700 DEG 10[minute] = 8 = 60 gray cast iron, ductile iron and small steel casting filterFiltration of copper water filtering net 1200 C 1700 C 10[minute] = 6 = 60 copper alloy castings

Aluminum filtered water filtering net 700~800 10[minute] is more than or equal to 900 DEG C 6 = 30 aluminum alloy castings

- Q: On the issue of their own screen printing

- Printed clothes must first have a printed version of the screen, clothing version with 120 or 130 mesh screen to do, with the version, scraper, ink, you can start printing color clothes need color, only one color

- Q: What is the process of the screen printing process?

- Carton printing, that is, directly in the already made a good corrugated boxes or other cartons, cartons for screen printing; ③ secondary processing, that is, first in the cardboard on the screen printing, and then according to the need to produce corrugated cardboard

- Q: How to get the correct fishing wire

- buy a network, according to the river in the more common size of the fish to buy, on the fingers, such as three fingers, four fingers and the like.

- Q: Screen printing, how to print circular arc surface

- The cup is cylindrical, in the top of the screen will roll the cup, then the screen printing on the graphic part of the ink will be transferred to the cup.

- Q: Screen printing and other printing methods of the difference

- or the order quantity is not high, from a few to tens of thousands of pieces can be operated. Ink layer thick, thick color. Generally less printed continuous tone, mostly in the field of color majority.

- Q: How to clean the screen plate

- The screen will often be in the printing process, there are ink, silver paste, glue and other residues will be affixed to the hole wall, and the use of silk screen stencil cleaning machine can prevent manual cleaning is insufficient, resulting in the residue in the air curing, so that

- Q: Screen printing has several characteristics

- On the use of hand-painted film or photochemical plate method of making screen printing plate.

- Q: Screen printing, how to choose the screen

- You have to choose according to different moments, printing different products, imports a little better

- Q: Screen printing and printing the difference

- The stencil printing includes transcripts, engravings, stencils and screen printing. The principle of stencil printing is: the printing plate (paper version or other version of the foundation to produce through the ink hole) in the printing, through a certain pressure to the ink through the hole version of the hole transferred to the substrate (paper, ceramics ), The formation of images or text.

- Q: What is the principle of screen printing?

- When printing, the ink through the mesh of the mesh on the substrate to re-form graphics / text.

Send your message to us

filter net,Sonim oxide and various inclusions

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 20000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords