4x8 Sheet of 3/4 Inch Film Faced Plywood from China with 8 Years' Experience

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Quick Details

| Type: | Plywoods | Place of Origin: | Shandong, China (Mainland) | Brand Name: | CHANTA |

| Model Number: | Commercial Plywood, Film Faced Plywood, Fancy Plywood,Melamine Plywood | Grade: | First-Class, BB/BB;BB/CC;BB/CC | Main Material: | Poplar |

| Formaldehyde Emission Standards: | E0 | Plywood Type: | 3/4/5/7/9/11/13/15/17-Ply Board & Veneer Board | Size: | 1220x2440mm,915x2135mm,2100x720mm |

| Thickness: | 3mm~21mm | Core: | poplar,combi,hardwood,birch | Face/back: | okoume, bingtangor,pencil cedar,birch,pine,keruing |

| Glue: | E2,E1,MR,WBP | Moisture: | below 15% |

Packaging & Delivery

| Packaging Details: | Plywood packing with 4x8 steel straps. |

| Delivery Detail: | 5-20 days after receiving LC or deposit |

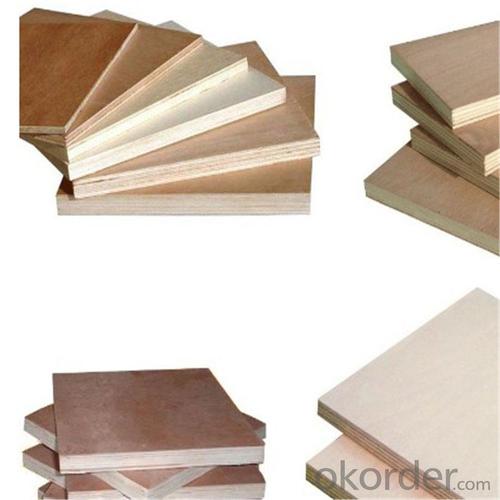

| Commercial plywood |

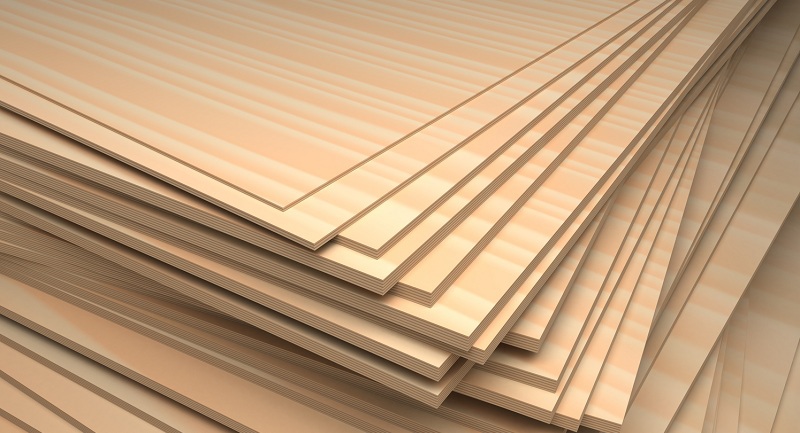

Plywood is a sheet material manufactured from thin layers or "plies" of wood veneer that are glued together with adjacent layers having their wood grain rotated up to 90 degrees to one another. It is an engineered wood from the family of manufactured boards which includes medium-density fibreboard (MDF) and particle board (chipboard). | ||

Face/Back | Okoume, Bintangor, Pencil Cedar, Keruing, Poplar, Birch,Pine,Maple, Hardwood, Ash, Oak and as your requested | |

Core: | Poplar, Hardwood, Hardwood Combi, Birch, eucalypts, as your requirement. | |

Grade: | BB/BB, BB/CC, CC/CC, CC/DD,DD/EE, etc. | |

Glue: | MR/E0/E1/E2 | |

Size(mm) | 1220*2440mm,1250*2500mm,915*2135mm,915*1830mm | |

Thickness(mm) | 2.0-25.0mm | 1/8inch(2.7-3.6mm) |

1/4inch(6-6.5mm) | ||

1/2inch(12-12.7mm) | ||

5/8inch(15-16mm) | ||

3/4inch(18-19mm) | ||

Moisture | 10-15% | |

Thickness tolerance | Less than 6mm | +/-0.2mm to 0.3mm |

6-30mm | +/-0.4mm to 0.5mm | |

| Usage | Usage adequate for making furniture or construction, package or industry, | |

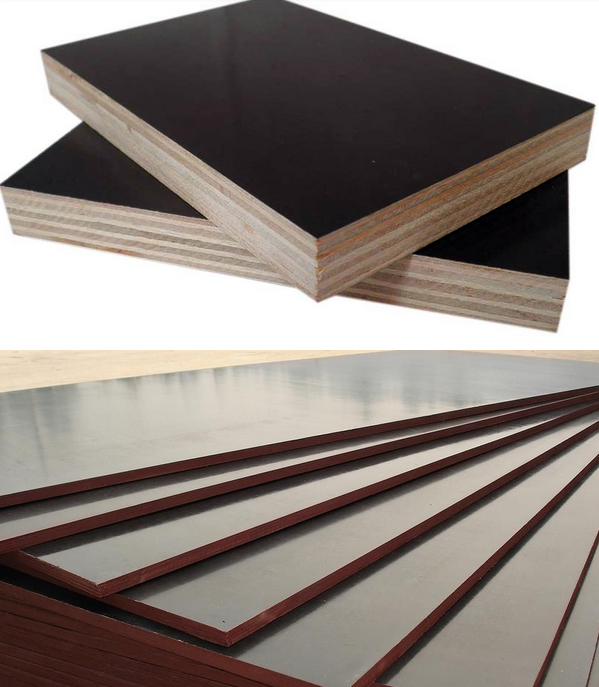

Features: 1 wear-resistant,anti-cracking,anti-acid and alkaline-resistant 2 no color cotamination between the concrete and shuttering board 3 can be cut int samll size for reusing. | ||

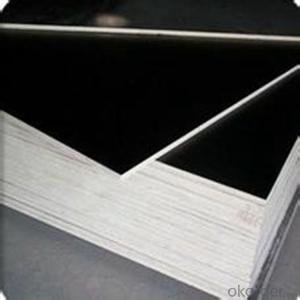

| Film Faced Plywood |

Product Name | Film faced plywood |

F/B | Black film, brown film,red film |

Grade | Construntion grade(one/two time hot press) |

Core | Poplar, hardwood, birch, pine, combi , and so on |

Glue | mealmine and WBP |

Thickness | 9-25mm |

Specification | 1220x2440mm, 1250x2500mm,915x1830mm |

Moisture Content | 8-10% |

Package | Standard export packing |

Press | one times press/two time press grade |

Supply Capacity | 4500 cbc/month |

Usages | Can be widely used for building concrete, etc |

Remarks | Top class equipment with top class produce technique; Credit first, fair trading |

Formaldehyde Emission Standards | E2<30mg/100kg E1<9mg/100kg E0<5mg/100kg |

| Fancy Plywood |

Fancy Plywood is a sheet material manufactured from thin layers or "plies" of wood veneer that are glued together with adjacent layers having their wood grain rotated up to 90 degrees to one another. It is an engineered wood from the family of manufactured boards which includes medium-density fibreboard(MDF) and particle board (chipboard). The surface is natural or engineered veneer. | ||

Face/Back | Any natural and Engineered Veneer as request | |

Core: | Poplar, Combi, Harewood, MDF | |

Grade: | AAA, AA, A | |

Glue: | MR/E0/E1/E2 | |

Size(mm) | 1220×2440mm, 915×2135mm | |

Thickness(mm) | 2.0-18.0mm | |

Moisture | 9%-14% at time of shipment | |

Thickness tolerance | ±0.1mm | |

| Melamine Plywood |

Face/Back | Melamine film | |

Core: | Poplar, Combi, Harewood, MDF | |

Grade: | AAA, AA, A | |

Glue: | MR/E0/E1/E2 | |

Size(mm) | 1220×2440mm, 915×2135mm | |

Thickness(mm) | 2.0-18.0mm | |

Moisture | 9%-14% at time of shipment | |

Thickness tolerance | ±0.1mm | |

| Packaging & Shipping |

Packing | Inter packing:0.2mm plastic; Ourter packing:bottom is pallets, covered with plastic film,around is carton or plywood, strenghthen by steel or iron 3*6 | |

Quantity | 20GP | 8pallets/21M3 |

40GP | 16pallets/42M3 | |

40HQ | 18pallets/53M3 | |

Usage | Usage adequate for making furniture or construction, package or industry, | |

Minimum Order | 1*20GP | |

Payment | TT or L/C at sight | |

Delivery Time | 3~15 days receiving deposit or original L/C at sight We have professional document and shipping department to provide the best service. | |

| Quanity Contral |

We have 6 QC teams to inspection such as moisture control, glue inspection both before production and after

production, material grade selection, pressing checking, and thickness checking.

Our aim is to supply high quality product with reasonable price.

- Q: What are the further processing of plywood?

- plywood plywood through mechanical finishing or gluing, such as cutting, profiling sawing, hitting, drilling, milling and other processed plywood

- Q: Multilayer plywood with what method is fixed

- Plywood is cut from the wood section into a veneer or cut from the wooden square cut into thin wood, and then made of adhesive glue from the three or more layers of plate-like materia

- Q: The density of the plywood is greater than that of the same kind of wood

- The greater the unit pressure when gluing, the greater the density of the plywood. As the wood at high temperature easy to produce plastic deformation, hot glue gluing than the compression of the compression rate is greater.

- Q: Ordinary plywood is divided into four categories

- Thickness specifications for the 6,9,12,15,18 and so on. The main performance indicators for the water content of 4 to 13%, the expansion of water thickness ≤ 12%, as well as tensile strength, bending strength, grip nail force.

- Q: What is the difference between plywood glue E0E1?

- Urea-formaldehyde glue: moisture-proof glue / for interior decoration, furniture, can not be used for outdoor.

- Q: Now the market prospects for plywood

- total accumulated profit 3,198,494,000 Yuan, compared with the same period in 2005 increased by 60.41%.

- Q: What is a joinery board?

- Blockboard thickness specifications for the 16,19,22,25 mm quality grade is divided into one, two, three three levels

- Q: What are the defects of the plywood?

- dead dead knots formed by the dead branches of trees, knots surrounded by the surrounding wood together, or even only part of the length of its cross-section of the length of about 1/4 or less than 1/4 , Texture hard or soft, and sometimes fall off the formation of empty.

- Q: Plywood in the processing of defects

- Separation delamination The separation of two adjacent veneers due to lack of glue or poor glue.

- Q: What is the plywood made of wood?

- Plywood is cut from the wood section into a veneer or cut from the wooden square cut into thin wood, and then made of adhesive glue from the three or more layers of plate-like material

Send your message to us

4x8 Sheet of 3/4 Inch Film Faced Plywood from China with 8 Years' Experience

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords