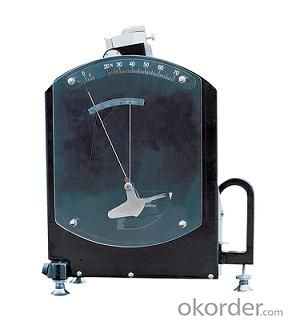

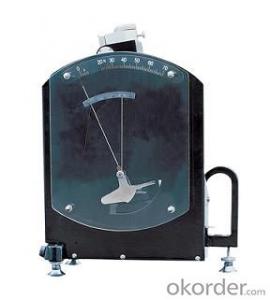

FIBRE BUNDLE STENGTH TESTER

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

SPECIFICATIONS

YG011 fiber bundle strength tester is an instrument to check the holdingstrength and elongation at breakage of fiber tufts

APPLICATION

STELOMETER is an instrument to check the holding strength and elongation at breakageof fiber tufts.

Holding strength reading on a graduated scale from 0 to 7 kPa (step0.1kPa), elongation reading on a graduated scale from 0% to 50%.

STANDARDS

Standard | ISO 3060 |

Note: this tester can conform to but not limit to the standards above, formore standards conformance, please contact us.

FEATURES

l Calibrate each stelometer by force measuring andelongation devices that are special designed by our company only, ensurepointer indications (force value and elongation) are match to real value andkeep test result stable and high accuracy;

l Special designed table clamps and pressley clamp (we aresupplier for USTER) can hold fiber tufts effectively, and avoid slipping oraffect test as hold tight;

l Read test values of breaking strength and elongationdirectly from two scales after finishing test;

l After fiber tufts breaks, there is no malfunctionmistakes;

l Test result with high accuracy and with good correlationwith yarn strength.

Standard Configuration of Fiber Bundle Strength Tester:

Thickness of sample holding clamp | 11.8mm |

Thickness of separator | 3.2mm |

Test Range | Breaking Load 20N-70N Elongation 0-50% (3.2mm) |

Applying load speed | 10N/s, adjustable |

Correction Coefficient (approxi.) | 0.9-1.1 |

Environment | Temperature be 20±2°C, Relative humidity be (65±3)%) |

Dimension | 320 x390 x160mm |

Weight | 10kg |

- Q: How to judge the fan left and right rotation?

- The No power fan is the use of natural wind and indoor and outdoor temperature difference caused by air heat convection, to promote the turbine rotation to the use of centrifugal and negative pressure effect of indoor fresh air is not fresh

- Q: What is the difference between a volute fan and a centrifugal fan?

- Centrifugal fan cover is a volute, is to increase its static pressure head and high pressure section of the fan efficiency. After the volute centrifuge fan removed the volute, the majority of the air volume range (high pressure area) of the static pressure head is lower than the centrifugal fan with a volute

- Q: What is the working principle of centrifugal fans?

- The pressure generated in the centrifugal fan is greatly influenced by changes in the inlet temperature or density. For a given intake air volume, the maximum intake air temperature (lowest air density) produces the lowest pressure. For a given pressure and flow characteristic curve, there is a power and flow characteristic curve. When the blower runs at constant speed , The required power increases with a decrease in the intake air temperature for a given flow rate.

- Q: What is the difference between the fan and the compressor?

- The At this time where the first compression, and then with the continuous rotation, the compression chamber volume is reduced. Since the compression process is carried out under full back pressure. Thus inefficient. Noise.

- Q: What are the characteristics of high-pressure axial fans?

- 2. High reliability When the use of changes, the machine can still operate safely. In addition to the impeller, the high pressure blower has no other action, so the reliability is almost free of maintenance. It has the following advantages: high compression ratio; low bearing running temperature; long life of lubricating grease; maintenance-free.

- Q: Fire high temperature exhaust fan is a centrifugal fan?

- Identify the axial fan and centrifugal fan, first from the two air flow to look. The air of the axial fan is 180 degrees

- Q: What is the difference between general-purpose inverter and fan-type inverter

- Machine tool spindle and rolling mill, paper machine, plastic film production line in the coiler, unwinding machine and other required torque, roughly inversely proportional to the speed, which is the so-called constant power load

- Q: How to install the axial fan?

- 2, to see how much air flow fan you need, and the fan inlet and outlet also need to receive air duct? If you need to know the length of the duct, and see the duct is straight pipe or elbow, three links (such as more elbow, three links, etc. need to increase the wind pressure);

- Q: What kinds of fans can be divided according to the use of material classification?

- 5. Fan in the form of pressure can also be divided into single, double or multi-stage pressure fan

- Q: What is the working principle of the suction blower?

- Take the fan as an example: observe the fan blade, the blade has an angle. When the blade is rotated, the air is cut, and the side of the blade is expelled from the air, resulting in an increase in the local pressure of the air, an increase in the air density (the power to automatically return to normal pressure)

Send your message to us

FIBRE BUNDLE STENGTH TESTER

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords