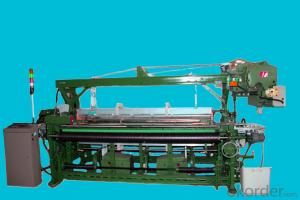

Weaving Machinery H

- Loading Port:

- China Main Port

- Payment Terms:

- TT

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 2 Sets Per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification of Weaving Machinery H

1. special medical gauze & bandage weaving machine,plain fabric

2. Machine working width:150cm

3. Fabric max width:145cm

4. Fabric min width:80cm

5. R.P.M:500-600

6. Mechanical take-up,mechanical let-off

7. Thread count:7-20pick per inch

8. Cotton yarn:25s-40s

9. warp beam diameter:800mm ,cloth roller diameter will be 800mm at most.

10. loom motor power:1.3kw

11. electricity consumption:1.5kw/h

12. air consumption:0

13.one air pump is installed in the machine

Packaging & Delivery of Weaving Machinery H

Packaging Detail: Pallet packing for long distance

Delivery Detail: 30-35days after reveive deposit or original L/C

Feature of Weaving Machinery H

1.Adopts the cam with eccentric shaft structure for making terry motion and replaces the old type of knocking bill motion structure. It assures the machine having high reliability of making terry and regulating conveniency.

2.Adopts shout crank arm beating-up motion, increasing greatly the beating-up force during weaving that assures the enough strength the weave the heavy towel.

3.thicker weft beating shaft assures enough beating rigidity, it can weaving the wide fabric more than 2800mm

4.adopts optimized six linkages weft insertion structure, make the weft insertion curve more soft

5.the two electromagnets which controlled the terry raising, controlled by technical program which set by electric control system, It can weaving high and low terry

6.the reed seat and other main parts made up of aluminum alloy, make the machine running faster more stable, more than 200rom speed make it the perfect model to replace the low speed towel rapier loom

- Q: How to judge the fan left and right rotation?

- From the motor side of the face, where the impeller in accordance with the clockwise rotation are called "right whirlwind" to the right; the other hand, is the "left fan" to the left.

- Q: What is the difference between a volute fan and a centrifugal fan?

- Centrifugal fans include a volute bulk fan (Housed centrifugal fan) and a voluteless centrifugal fan (Unhoused centrifugal fan).

- Q: How can a more intuitive distinction between centrifugal fans and axial fans?

- Because the gas flows parallel to the fan shaft. Axial fans are often used in situations where the flow rate is high and the pressure is low. The axial fan is fixed and moves the air.

- Q: Why should the safety valve be installed at the Roots blower exit?

- Even if the fan outlet is completely blocked (in fact, start the centrifugal fan should be closed the outlet) will not cause damage to the fan.

- Q: What is the operation of centrifugal fans and axial fans?

- Centrifugal fan is based on the principle of kinetic energy conversion to potential energy, the use of high-speed rotation of the impeller to accelerate the gas, and then slow down, change the flow, the kinetic energy into potential energy (pressure)

- Q: How to install explosion-proof axial fan?

- At the end of the fan must be installed winders, and hope to install protective net.

- Q: How to distinguish the high, medium and low pressure of the fan?

- High, medium and low pressure fan is its number of revolutions (n) to distinguish, n> 60 for the low pressure fan

- Q: What is the difference between a wind knife and an air knife?

- Air knife is the name suggests is to use air to dry, such as air compressor and so on.

- Q: What is the working principle of the suction blower?

- Take the fan as an example: observe the fan blade, the blade has an angle. When the blade is rotated, the air is cut, and the side of the blade is expelled from the air, resulting in an increase in the local pressure of the air, an increase in the air density (the power to automatically return to normal pressure)

- Q: Why does the fan start the current?

- The fan is a mechanical fluid that relies on the input of mechanical energy, which increases the gas pressure and sends the gas to the gas. It is a driven fluid machine.

1. Manufacturer Overview

| Location | Qingdao, China |

| Year Established | 2003 |

| Annual Output Value | 10-30Setyear |

| Main Markets | Mid East; Eastern Europe; Westen Europen |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao |

| Export Percentage | 80% |

| No.of Employees in Trade Department | 100 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 10000 square meters |

| No. of Production Lines | Above8 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Weaving Machinery H

- Loading Port:

- China Main Port

- Payment Terms:

- TT

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 2 Sets Per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords